Sealing sluice valve

A technology of gate valve and gate plate, which is applied in the field of gate valve, can solve the problems of large gap between casting and guide rail groove width of valve body, failure of transmission pair, etc., and achieve the effect of eliminating seal failure, solving failure and ensuring reliable bidirectional sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

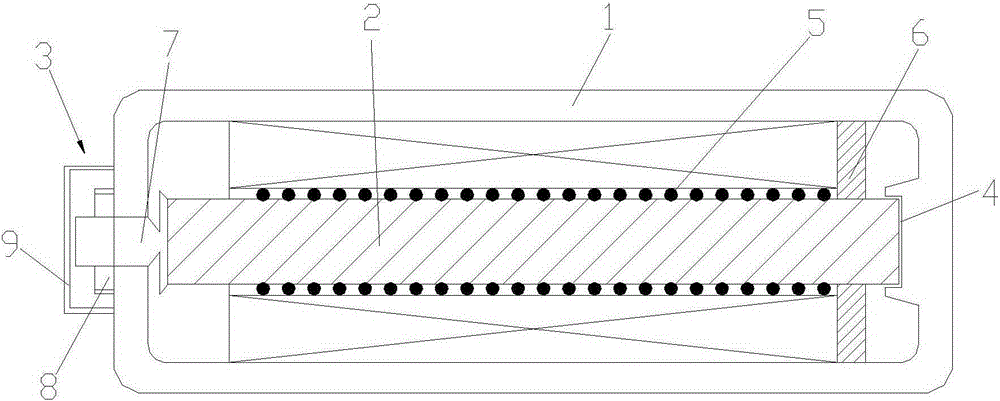

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 It is a sealed gate valve according to the present invention, which includes a valve body 1 and a gate plate 2; one end of the inner wall of the valve body 1 is provided with an adjusting and tightening platform 3, and the other end is provided with a guide rail 4; The tight platform 3 is arranged in the valve body 1 in cooperation with the guide rail 4; the upper and lower ends of the gate 2 are provided with sealing balls 5; the sealing balls 5 are evenly arranged on the upper and lower sides of the gate 2; the gate 2 is set There is also a sealing ring 6 at the end of the guide rail 4; the adjustable clamping platform 3 includes a clamping rod 7 and a nut 8; fixed; the nut 8 is provided with a sealing cover 9; the sealing balls 5 are arrayed on the upper and lower sides of the gate 2, and there are at least 18 on each side; the valve body 1 is made of stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com