Gate valve sealing structure

A sealing structure and gate valve technology, applied in sliding valves, valve devices, engine components, etc., can solve problems such as failure of transmission pair, large gap between casting and valve body guide groove width, etc. The effect of seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be explained below with reference to the drawings.

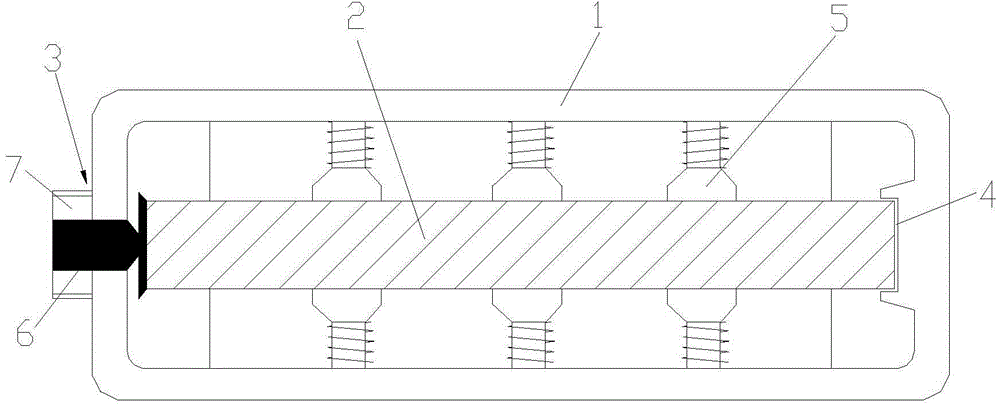

[0012] Attached figure 1 It is a gate valve sealing structure according to the present invention, which includes a valve body 1 and a gate 2; one end of the inner wall of the valve body 1 is provided with an adjusting jacking table 3, and the other end is provided with a guide rail 4; The tightening table 3 and the guide rail 4 are arranged in the valve body 1 in cooperation; the upper and lower ends of the gate 2 are provided with spring support columns 5, and the number of the spring support columns 5 is at least two groups, at least two in each group; The spring support column 5 pushes the gate plate 2 through the spring extension; the adjusting jacking table 3 includes a jacking rod 6 and a nut 7; one end of the jacking rod 6 pushes the gate plate 2 and the other end extends out of the valve body 1 and fix with nut 7.

[0013] According to a gate valve sealing structure of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com