Automatic water adding device for steam tank

A technology of automatic water filling and steam tank, which is applied in the direction of steam generation, water supply control, lighting and heating equipment, etc., which can solve the problems of contradiction between supply and demand and the inability to form steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

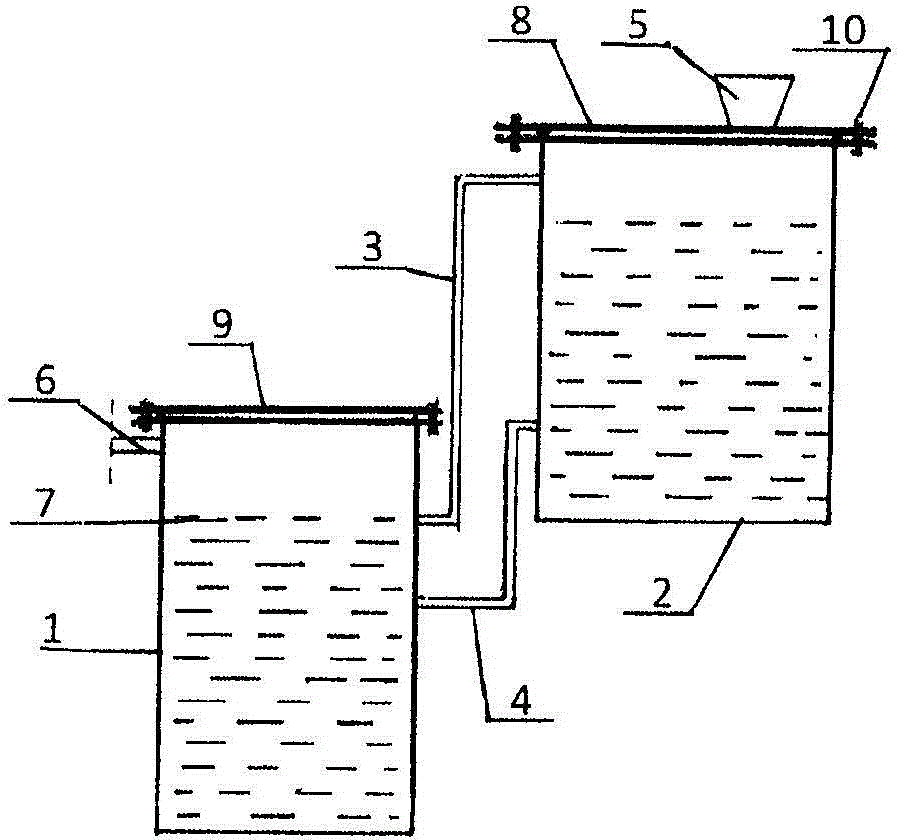

[0008] Further description will be made below in conjunction with the accompanying drawings.

[0009] refer to figure 1 , the installation position of the steam tank 1 is lower than the height of the water storage tank 2, the internal space of the two is filled with water that is not completely full and its horizontal surface 7, and the upper end of the air inlet pipe 3 on the top is located in the upper space area in the water storage tank 2, and its The inlet of the lower end is located inside the steam tank and is at the same level as the upper plane 7 of the water level. The upper inlet of the lower water delivery pipe 4 is located in the lower water in the water storage tank, and its outlet is located below the water level in the steam tank. A cone for adding water is installed on the upper top of the water storage tank. The bucket opening 5 is sealed with a fine sand bag (not shown in the figure) after adding water, and the steam output nozzle 6 is installed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com