Vacuum wall crawler

A crawler and vacuum technology, applied in the field of toothed belts, can solve problems such as expensive and complex manufacturing, and achieve the effect of a simple solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the following detailed description, the vacuum wall crawler 1 and the adsorption crawler unit 100 according to the present invention will be described through preferred embodiments.

[0062] The construction and operation of the vacuum wall crawler 1 is well known and therefore requires no further explanation in context. However, further details regarding the operation of the vacuum wall crawler 1 are provided below.

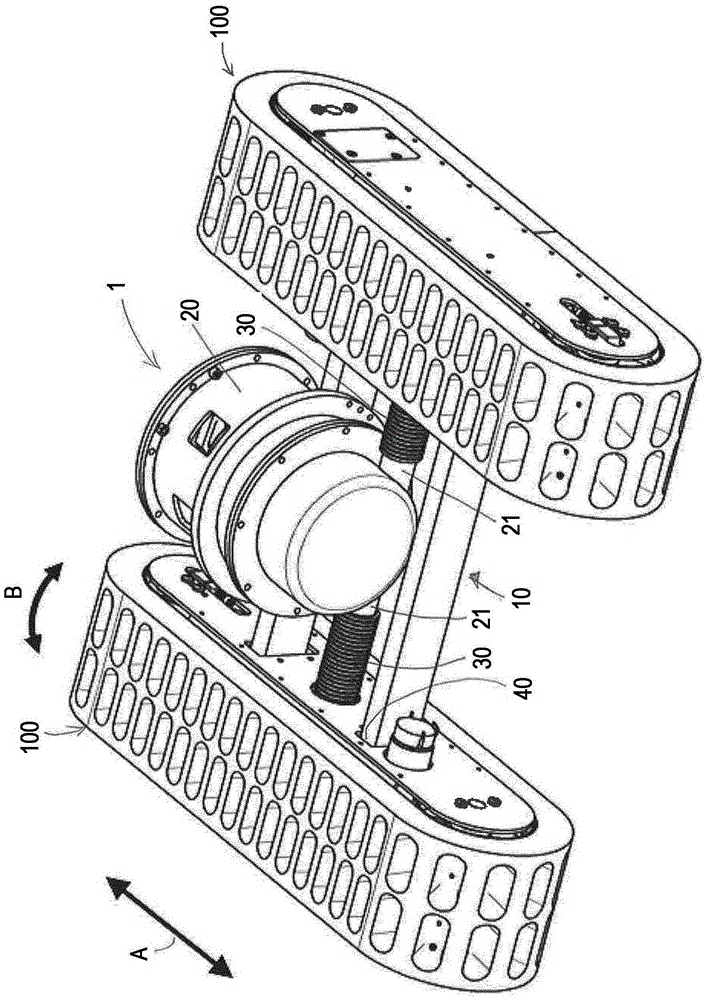

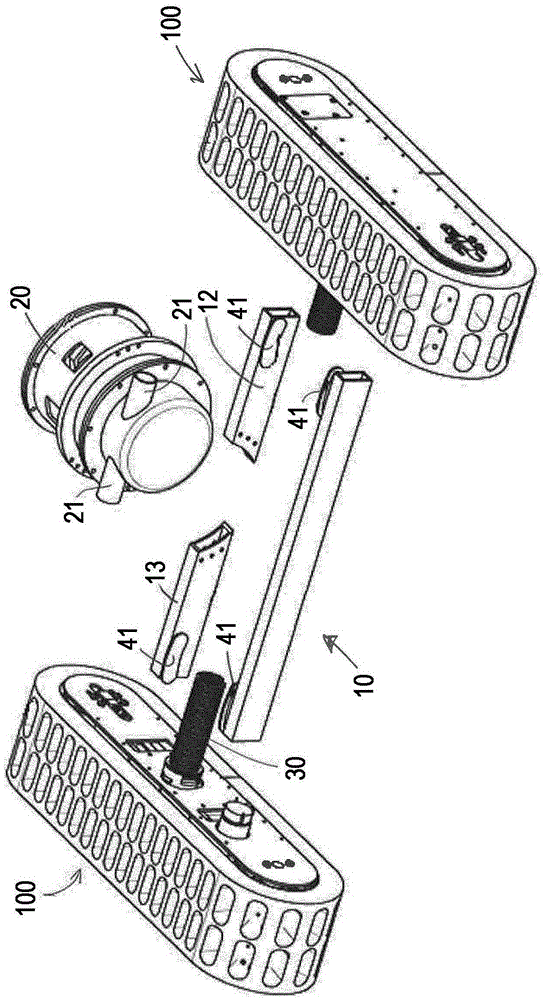

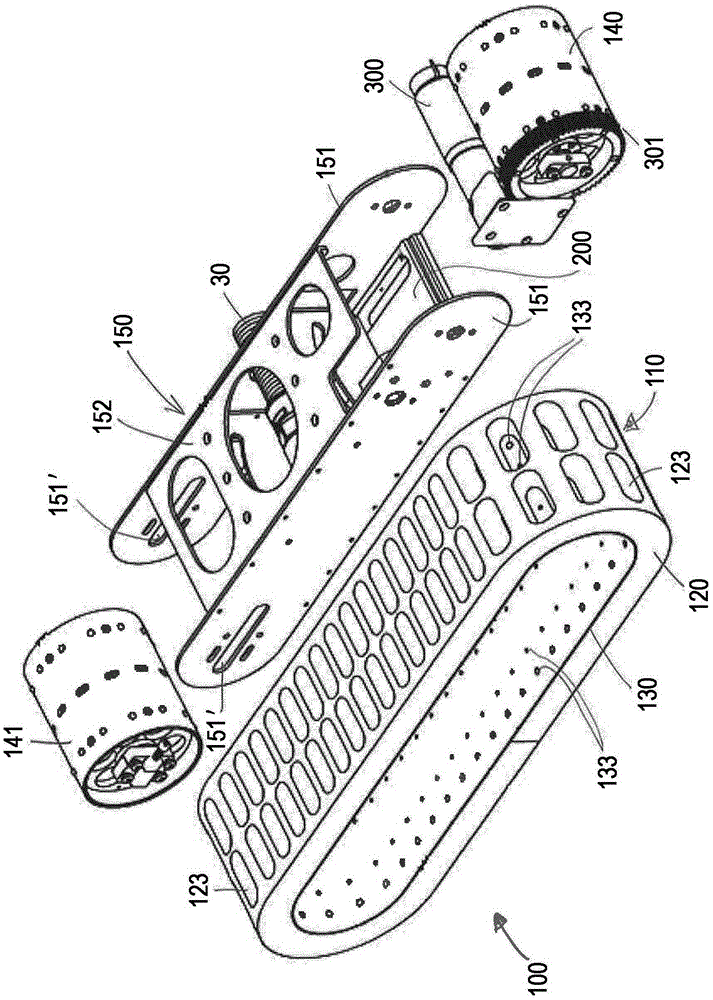

[0063] figure 1 A first exemplary embodiment of a vacuum wall crawler 1 is shown.

[0064] The vacuum wall crawler 1 is a mobile device that can be attached to a surface (eg a wall or ceiling etc.) by using one or more suction crawler units 100 . figure 1 The vacuum wall crawler 1 shown in has two suction crawler units 100 . The suction track unit 100 is connected to the main frame 10 by a joint 40 which allows the vacuum wall crawler 1 to adapt to the curved surface on which it travels, see below.

[0065] In other embodiments (not shown), the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com