Connection flange for double walled high pressure gas pipe

A double-walled pipe and flange technology, applied in flange connection, pipe/pipe joint/pipe fitting, pipe element, etc., can solve the problem that the connection is not modular.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

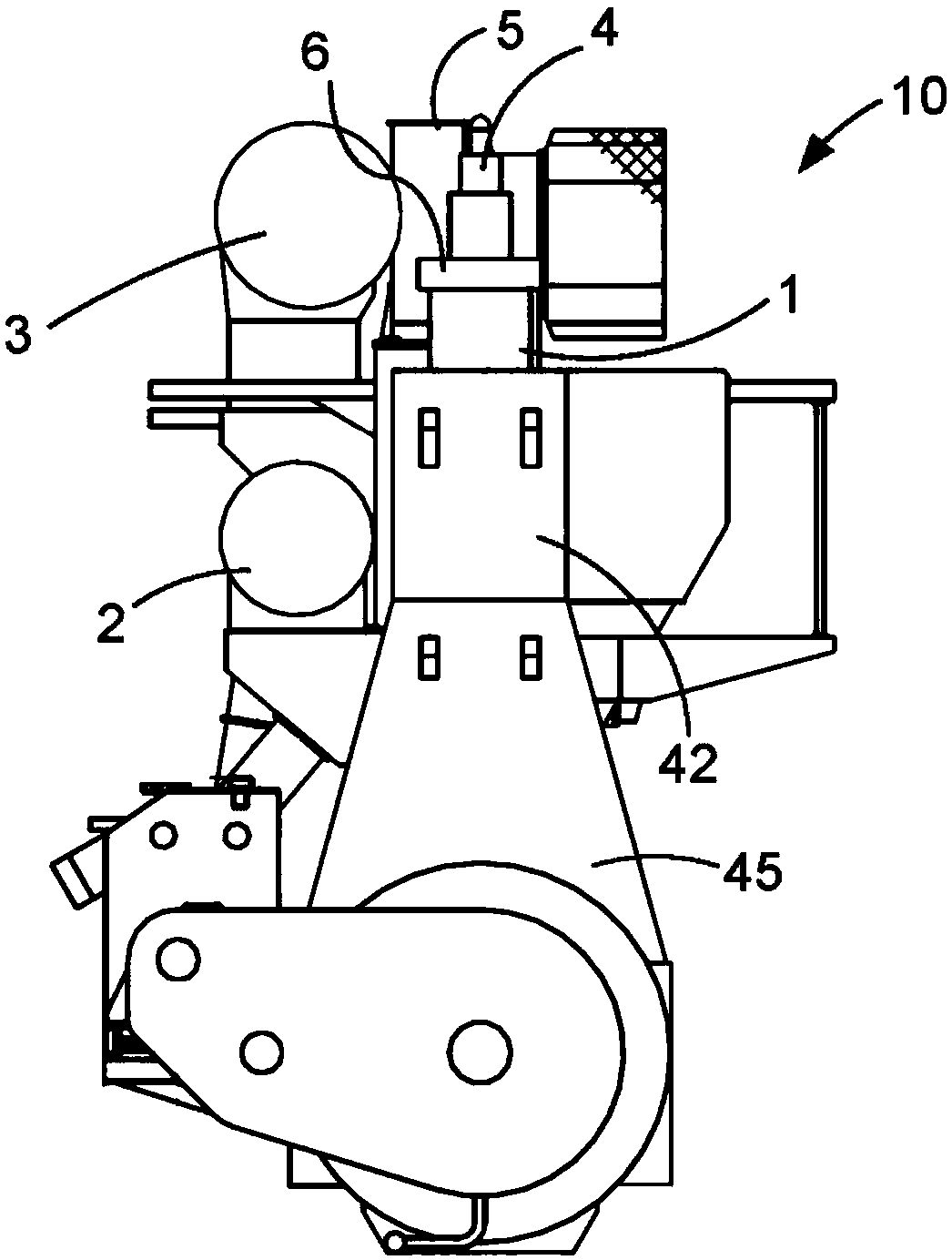

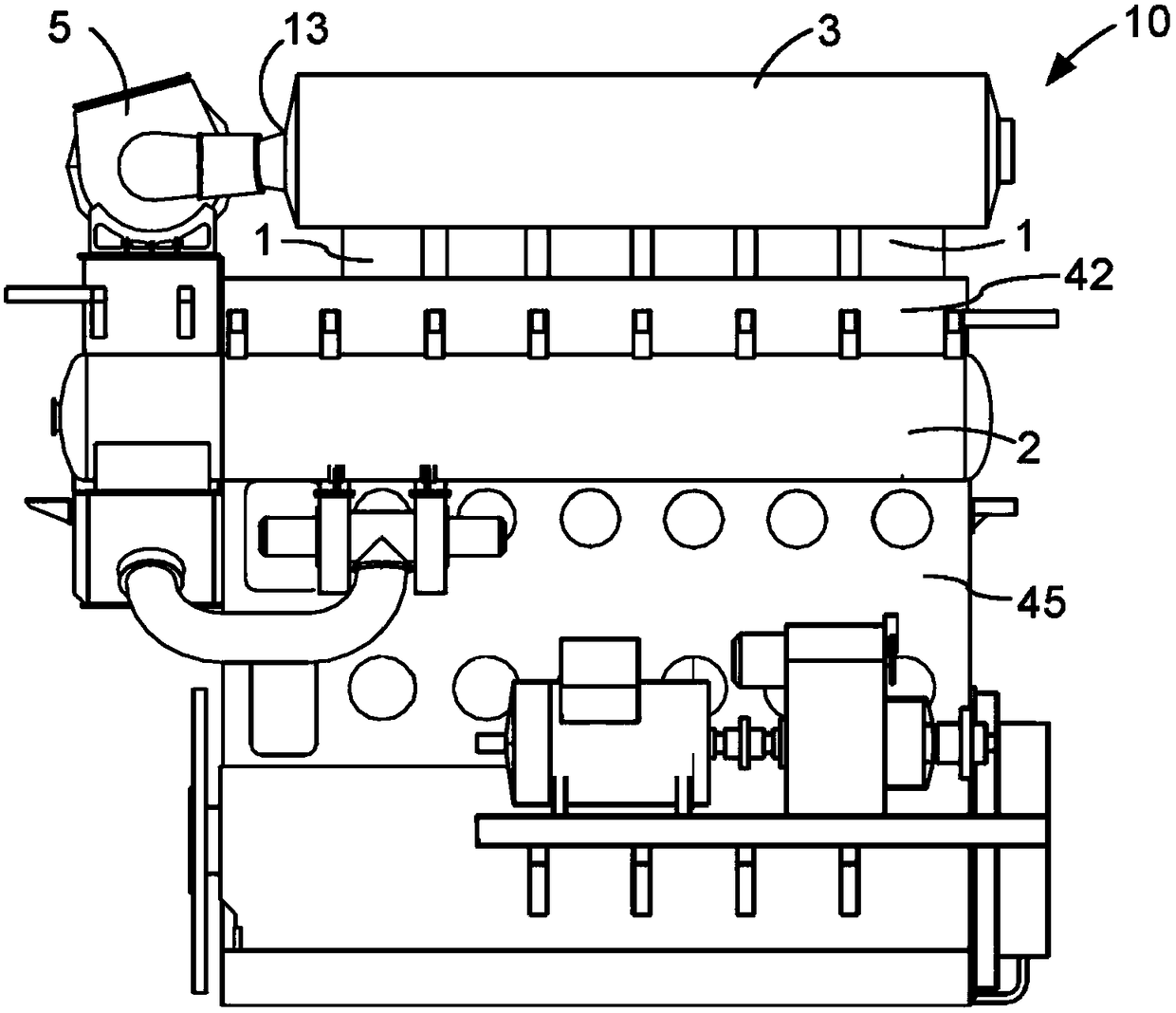

[0077] In the following detailed description, flanges, flange assemblies, and high pressure conduits will be described by way of exemplary embodiments. figure 1 with figure 2 A large low-speed turbocharged two-stroke diesel engine 10 with a crankshaft and crosshead and its intake and exhaust systems are shown. Large turbocharged two-stroke diesel engines typically have from 5 to 16 cylinders 1 in line, in this example six cylinders, carried by the cylinder frame 42. The cylinder frame 42 is carried on an engine frame 45 .

[0078] The engine 10 is a two-stroke single-flow engine having a scavenging port (not shown) in the lower region of the cylinder 1 and an exhaust valve 4 at the top of the cylinder 1 . Charge air is routed from a charge receiver 2 (also called a scavenging receiver) to the scavenging port of each cylinder 1 . A piston (not shown) in cylinder 1 compresses a charge, fuel is injected and then combusted to generate exhaust gases. When the exhaust valve 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com