Quartz gas discharge lamp providing photocatalytic oxidation

A photocatalysis and oxidant technology, applied in the parts, chemistry, tube/lamp screen manufacturing of gas discharge lamps, etc., can solve the problems of short life, low power output, unsatisfactory use of fluorescent lamps, etc., and the proportion or degree is easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

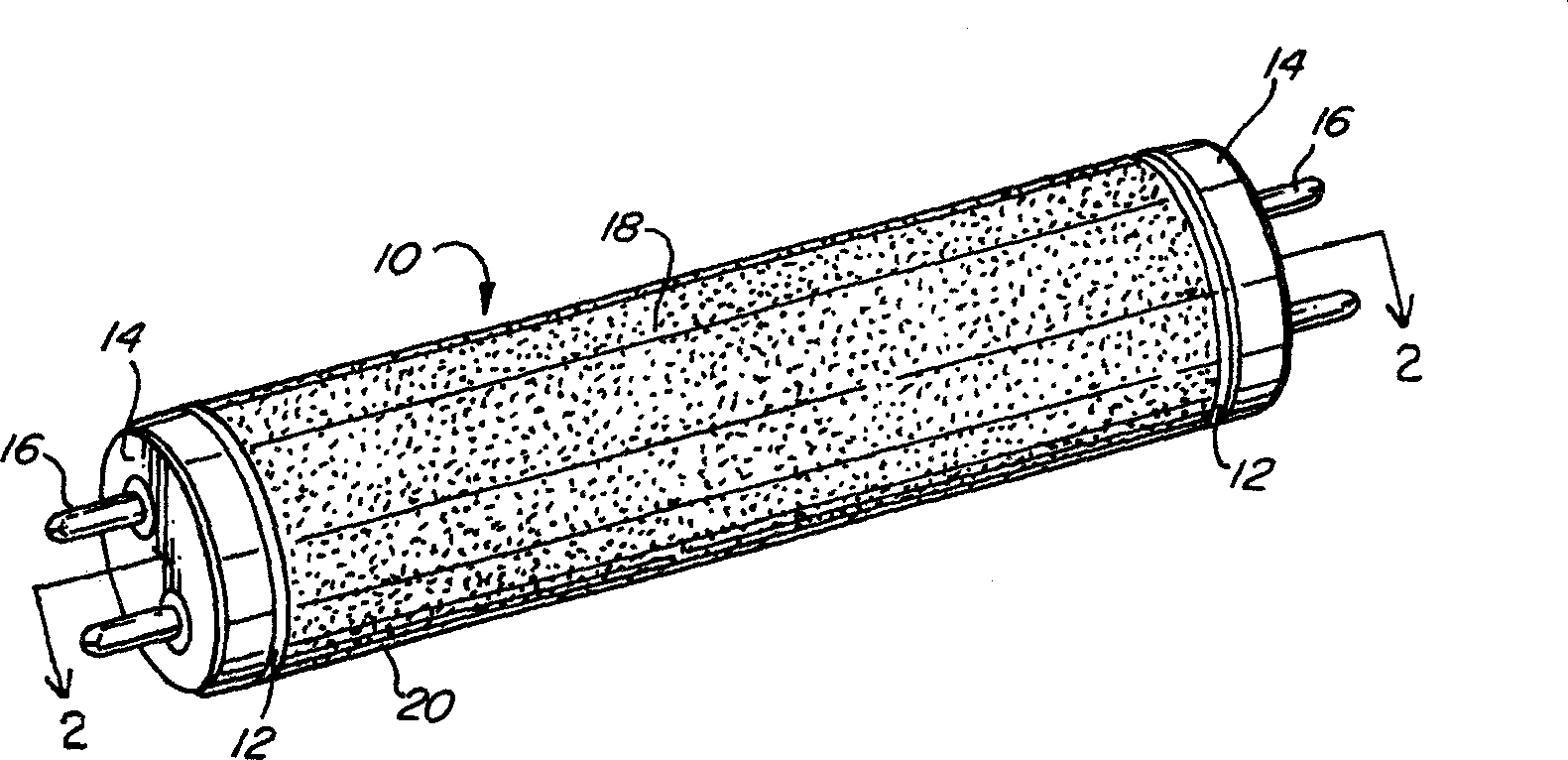

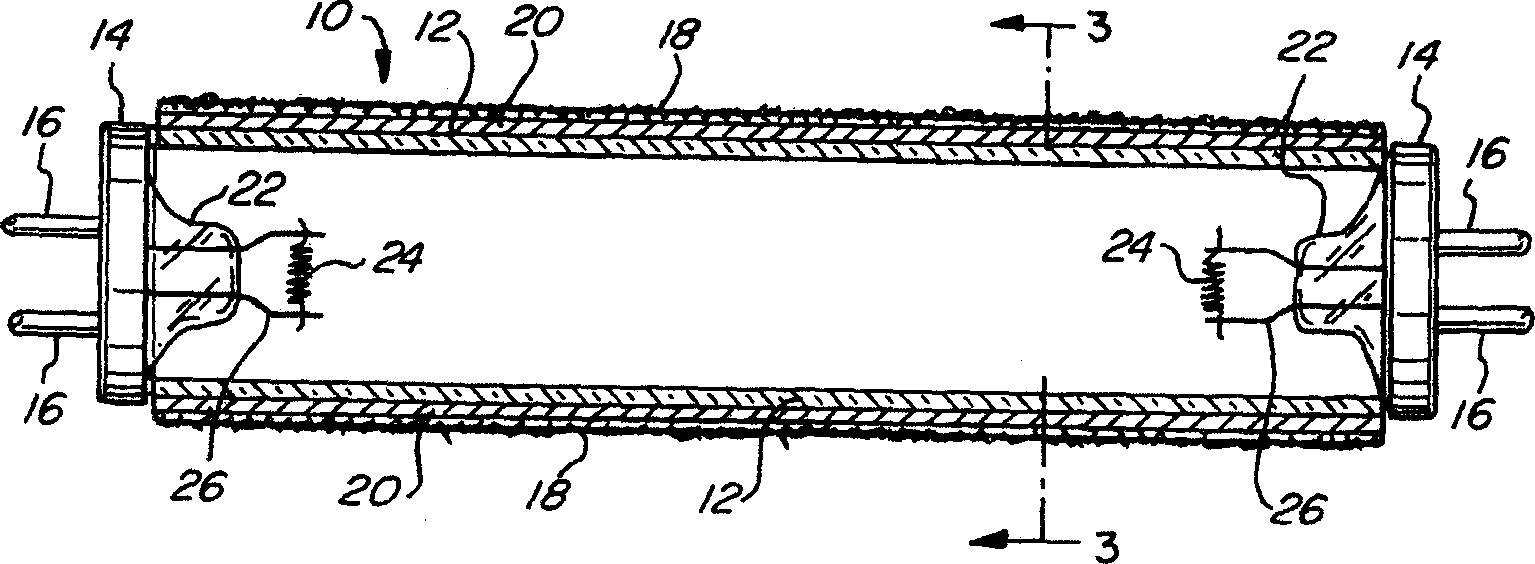

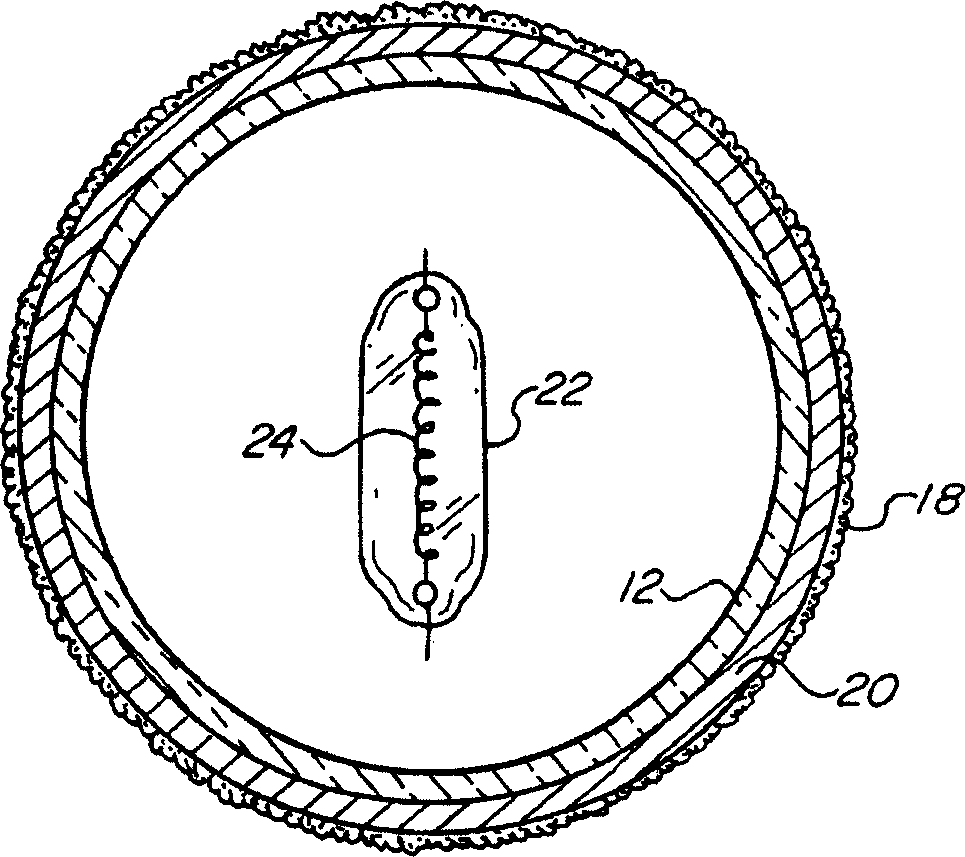

[0023] figure 1 is a schematic perspective view showing an embodiment of the present invention. This example shows a quartz gas discharge lamp 10 with a photocatalytic oxidation coating. The gas discharge lamp 10 has a quartz tube 12 provided with a spring case cover 14 . The spring case cover 14 is provided with contact pins 16 extending outward. A sleeve 20 is provided around the quartz tube 12 . The casing 20 is impregnated with titanium dioxide 18 . Sleeve 20 is preferably made of a material having a lower melting point than quartz tube 12 and titanium dioxide 18 . Sleeve 20 is preferably made of fluorinated ethylene propylene or other suitable fluorinated polymer (commonly available under the trade name Teflon). Fluorinated ethylene propylene sleeves are durable and able to withstand relatively harsh conditions. Fluorinated ethylene propylene sleeves are generally non-adhesive; however, titanium dioxide 18 can be impregnated or embedded into the sleeve when the slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com