Dust collector floor brush

A vacuum cleaner, ground technology, applied in the direction of the suction nozzle, etc., can solve the problem of large moving resistance of the floor brush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0046] A specific implementation case is introduced below, so as to understand the features and applications of the technology more clearly.

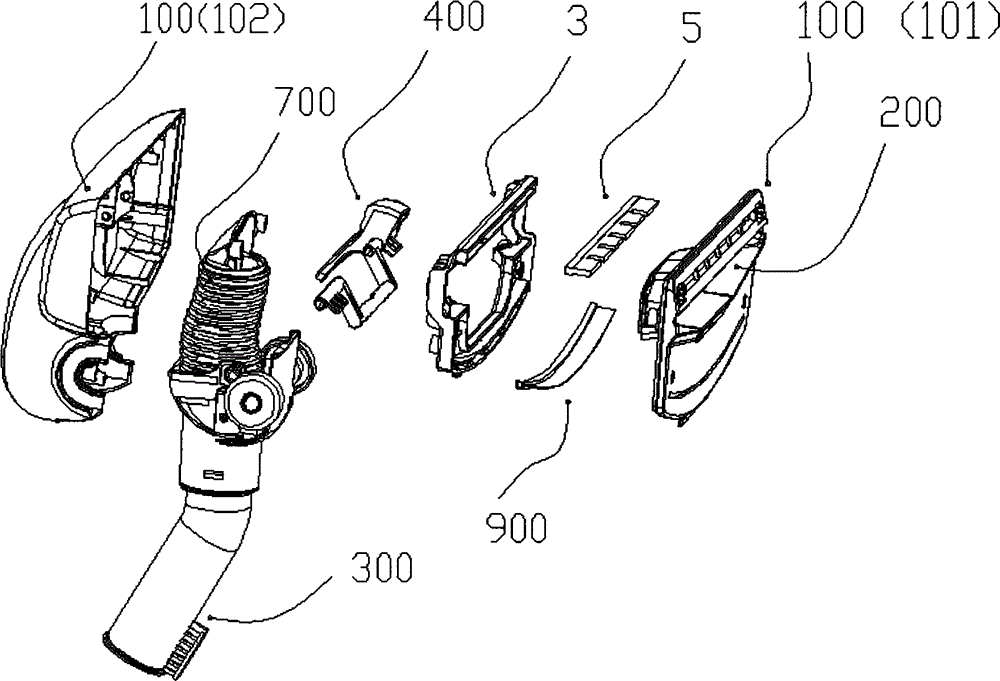

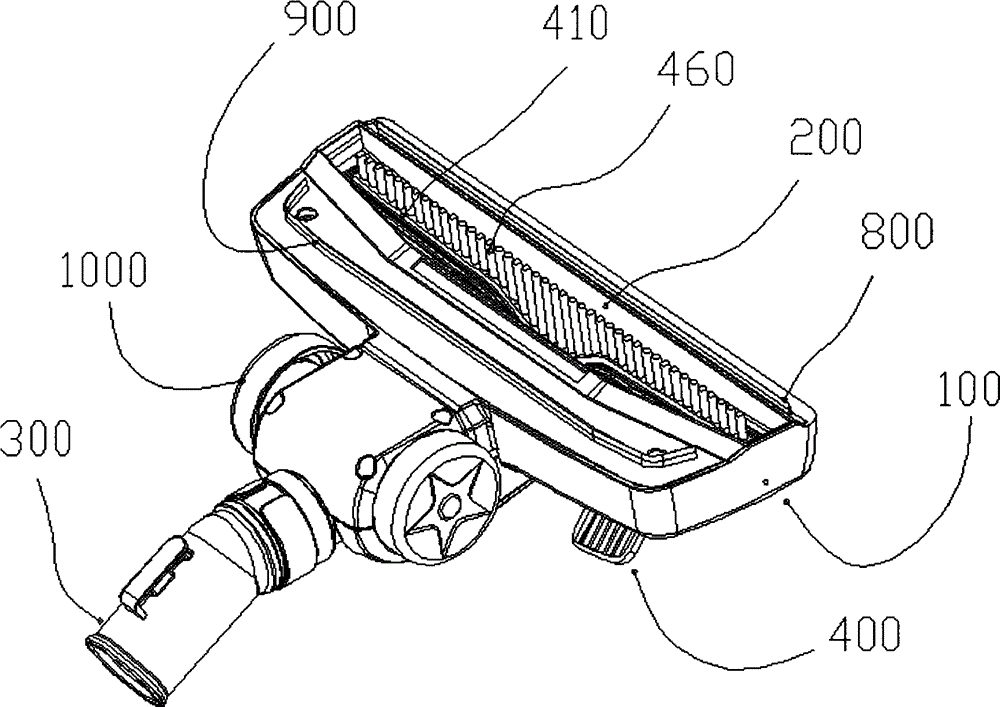

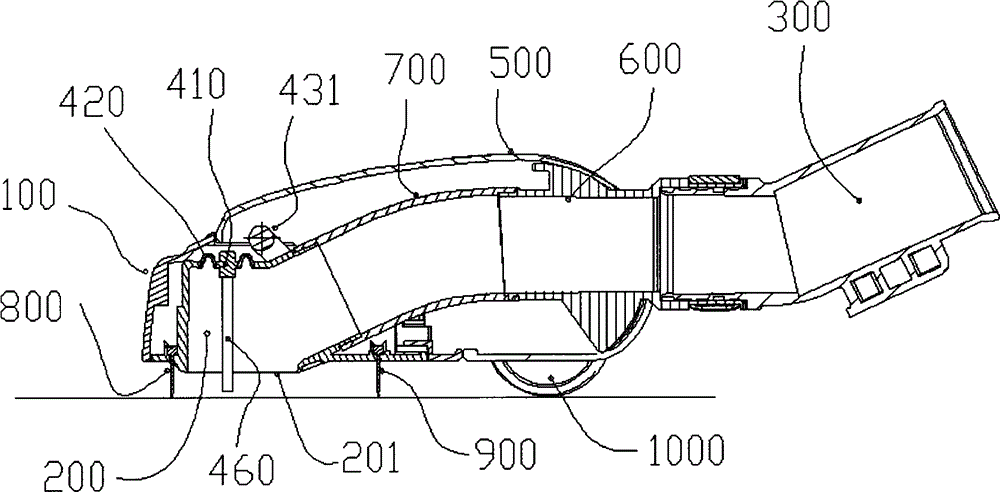

[0047] Such as Figure 5 , Figure 6 As shown, it is a specific embodiment of the present invention, which includes a ground brush body 100. The ground brush body 100 is composed of a ground brush bottom plate 101 and a ground brush surface cover 102. The bottom of the ground brush body 100 is set There is an air inlet chamber 200 into which dust-laden gas flows, and the air inlet chamber 200 faces the bottom plane 201 of the air inlet chamber on the ground, and there is an annular cutout 210 at the upper end of the air inlet chamber 200 . The lifting plate 410 is airtightly connected with the annular cutout 210 through the soft sealing apron 420 to form a part of the air inlet cavity 200 , so that external air can only flow in from the bottom plane 201 of the air inlet cavity. In practical applications, the soft sealing apron 420 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com