Steel wire rope surface grease

A technology of surface grease and steel wire rope, applied in the field of surface grease of steel wire rope, can solve the problems of high cost, poor drop point and low temperature performance of surface grease of steel wire rope, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the surface fat that embodiment 1~4 provides is:

[0026] Mix wax oil and solvent oil in proportion to obtain base oil, put it into the kettle, add thickener, viscous oil and microcrystalline wax, heat up and stir until uniform, when the temperature rises to 120-130°C, keep stirring for 30 ~50min, stop heating, add anti-rust agent when the temperature is lowered to 110-120°C, stir evenly to obtain steel wire rope surface grease.

Embodiment 1

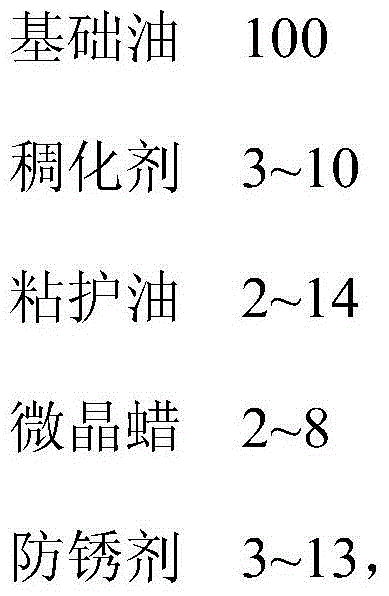

[0028] A kind of steel wire rope surface grease comprises following components:

[0029]

Embodiment 2

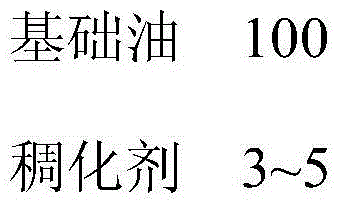

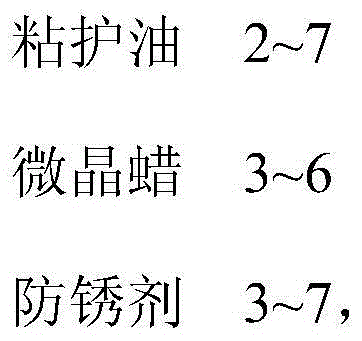

[0031] A kind of steel wire rope surface grease comprises following components:

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com