Plane low-friction spring and cam constant-force mechanism

A low-friction, cam technology, used in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problems of low stability of output torque value and narrow torque value range, and achieve less impact interference and strong versatility. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

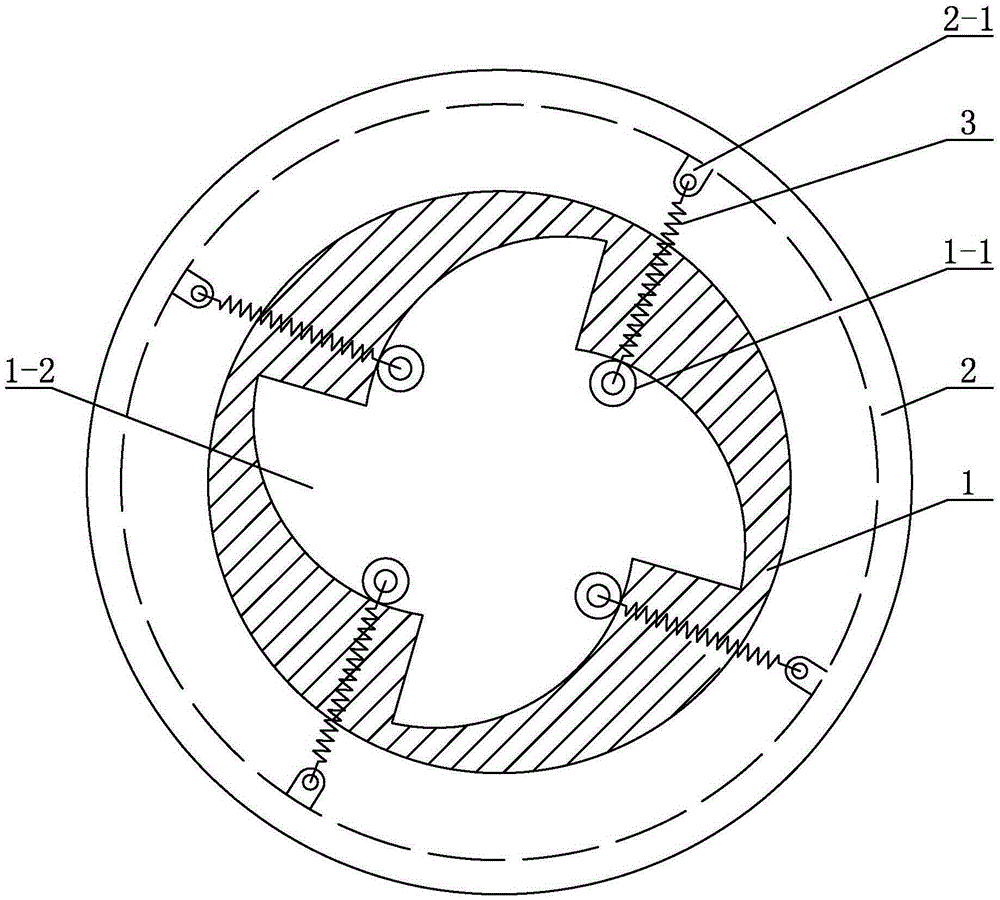

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, a flat low-friction spring cam constant force mechanism described in this embodiment includes a cam 1, an output end reel 2 and a plurality of springs 3, the cam 1 is arranged in the output reel 2, and the output end reel 2 A plurality of rollers 2-1 are evenly distributed along the circumferential direction on the inner side wall of the cam 1, and a plurality of articulated rings 1-1 are evenly distributed along the circumferential direction on the surface of the cam 1, and one end of each spring 3 is connected with a roller 2-1 Connection, the other end of each spring 3 is connected with a corresponding articulated ring 1-1.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To illustrate this embodiment, each spring 3 of the planar low-friction spring cam constant force mechanism described in this embodiment is made of a cylindrical helical tension spring. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the plurality of springs 3 of a flat low-friction spring cam constant force mechanism described in this embodiment refers to four springs 3, and the plurality of articulated rings 1-1 refers to four articulated rings 1-1 , a plurality of rollers 2-1 refers to four rollers 2-1. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com