Spring, cam and torsion bar type constant force mechanism

A cam mechanism and torsion bar technology, applied in the field of passive adaptive constant force loading mechanism, can solve problems such as difficulty in adapting to various tasks, failure to achieve large torque output, low torque value, etc., and achieve easy constant force feedback closed-loop control , small inertia and adjustable torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

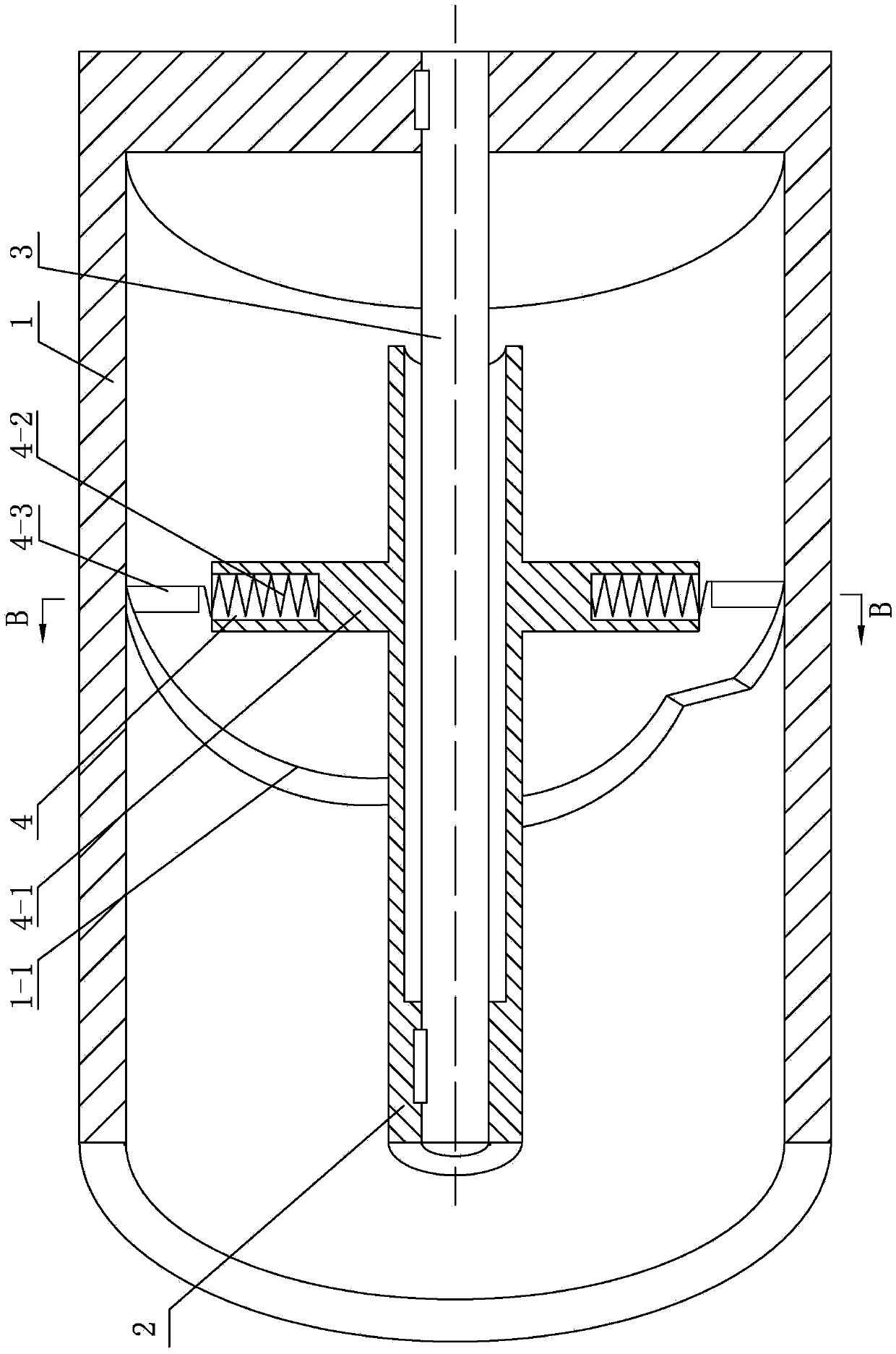

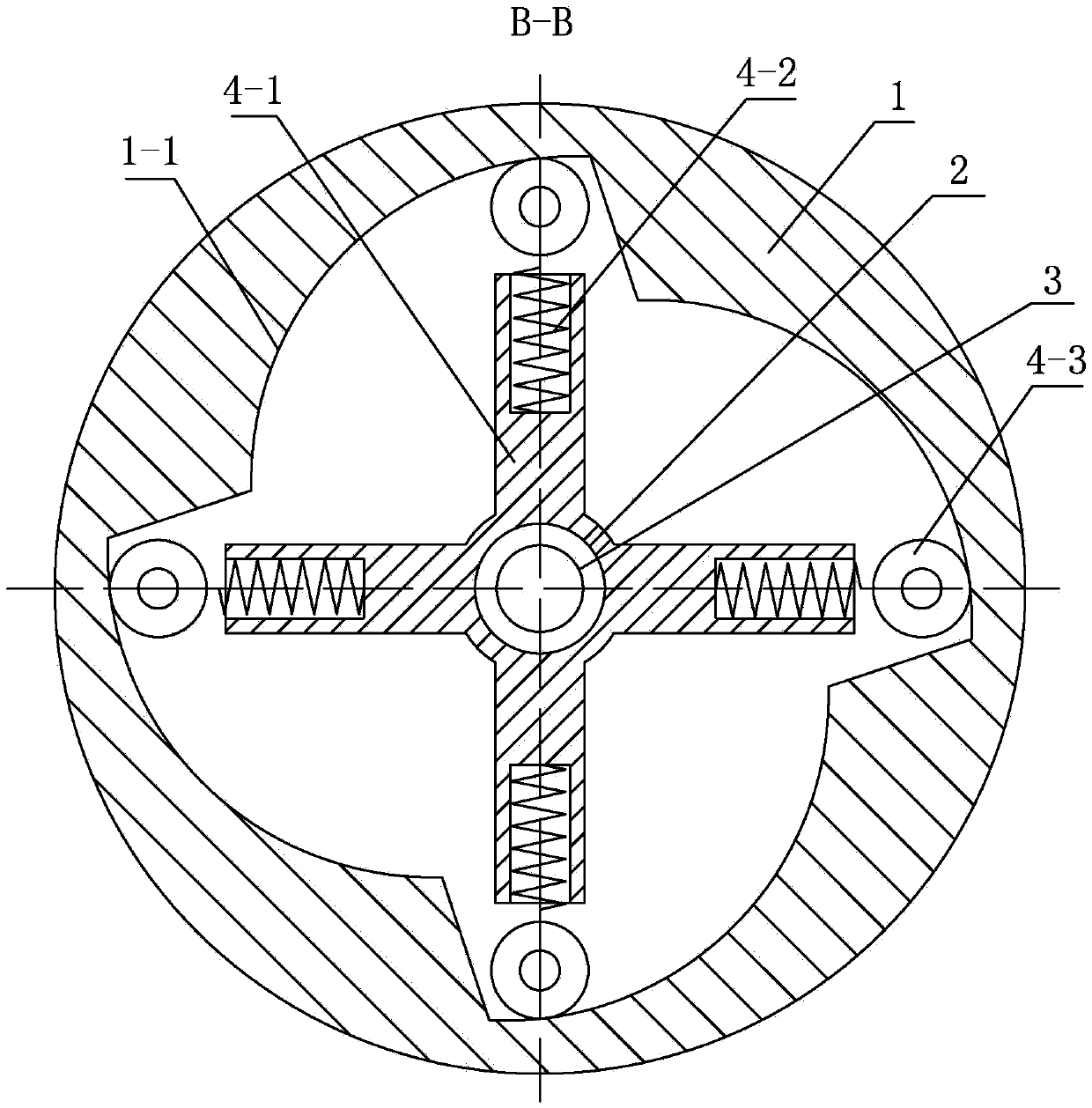

[0009] Specific implementation mode one: combine Figure 1-Figure 2 Explain that the spring cam torsion bar type constant force mechanism of the present embodiment includes an output reel 1, an input shaft 2, a torsion bar 3 and several groups of spring cam mechanisms 4, and each group of spring cam mechanisms 4 includes N sleeves 4- 1. N springs 4-2 and N rollers 4-3, wherein N is a positive integer;

[0010] Several groups of spring cam mechanisms 4 are arranged side by side in the output reel 1 along the axial direction of the output reel, and a torsion bar 3 is arranged in the hollow cavity of the input shaft 2, and the two ends of the torsion bar 3 are connected with the input shaft 2 and the output reel respectively. 1 is fixed, the sleeve 4-1 is a sleeve with grooves, and a plurality of sleeves 4-1 are evenly distributed along the circumference of the input shaft 2 on the outer wall of the input shaft 2, and there are arranged in the sleeve 4-1 The spring 4-2, the two ...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 and figure 2 Note that the spring 4-2 in this embodiment is a cylindrical helical compression spring. The structure is simple and easy to use. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 2 Note that both the input shaft 2 and the torsion bar 3 in this embodiment are cylindrical structures. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com