A communication device used in waste incineration system

A technology of waste incineration and communication, which is applied in the field of Unicom devices and Unicom devices in waste incineration systems, can solve the problems of shortening the service life of Unicom devices, economic losses of environmental protection service enterprises, frequent maintenance of Unicom devices, etc., and achieves significant economic benefits and structure. Novel, saving castable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

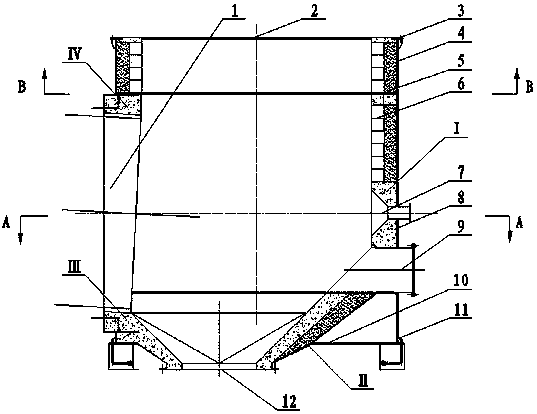

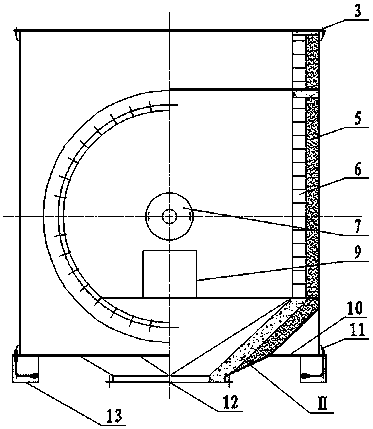

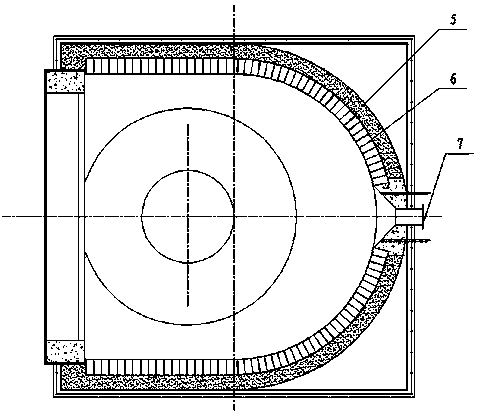

[0021] figure 1 , 2 Among them, the present invention includes a cylinder assembly 4 and a cylinder bottom 10 . Among them, the upper end of the cylinder assembly 4 is welded with a flange 3, and the right middle part has an observation port 7 for observing the situation in the communication device, and the lower right part of the cylinder assembly 4 has an inspection port 9 for irregular inspection and maintenance of equipment 1. A number of ribs 11 are welded between the cylinder assembly 4 and the cylinder bottom 10 in order to improve the structural strength. On the left side of the entire communication device, there is a connection port 1, which is externally connected to the rotary kiln tail through anchor bolts; at the top is a connection port 2, which is connected to the second combustion chamber through a flange; at the bottom is a connection port 3 12, which is connected through a flange External vertical furnace. Refractory castable 8 is poured in the area I near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com