Aero-engine simulation test bed on the basis of birotor simplified dynamic model design

An aero-engine and dynamic model technology, applied in simulators, instruments, control/regulation systems, etc., can solve the problems of complex model structure, low efficiency of quantitative analysis and calculation, and difficult to achieve qualitative analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

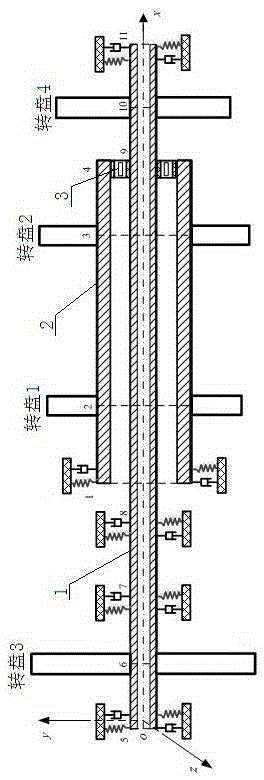

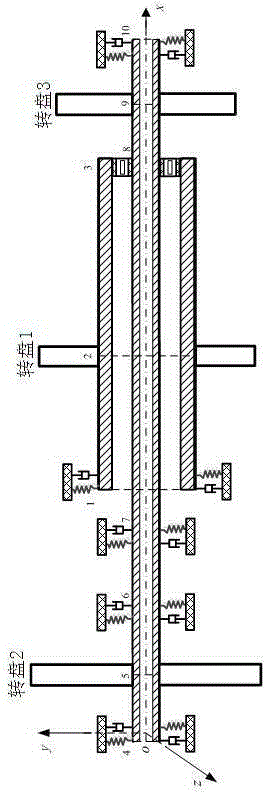

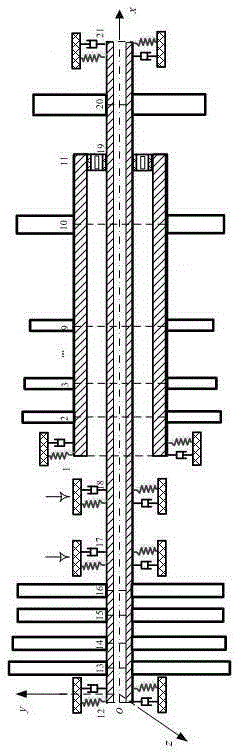

[0069] A kind of aero-engine simulation test-bed based on double-rotor simplified dynamics model design, its composition comprises: test-bed frame, described frame adopts the structure supporting low-pressure rotating shaft 1 of 6-point support and the high-pressure rotating shaft that is sleeved on the outside of low-pressure rotating shaft 2;

[0070] The dual-rotor system of an aero-engine adopts a 6-point support structure, in which the high-pressure rotor system adopts a two-point structure and adopts a 1-0-1 support method; the low-pressure rotor system adopts a four-point structure and adopts a 1-2-1 support method; The bearing supports in the dual-rotor system are numbered 1-6 from left to right, and bearing 5 is the intermediate bearing 3. According to the support structure and working principle of the aero-engine dual-rotor system, a relatively accurate complex dynamic discrete model ModelA of the aero-engine dual-rotor system with a 6-point support structure is esta...

Embodiment 2

[0106] According to the aero-engine simulation test-bed designed based on the dual-rotor simplified dynamic model described in Example 1, the critical speeds of the three models and the relative errors between the simplified model and the complex model under different elastic support coefficients. The support is an isotropic elastic support. In this paper, the dual-rotor system model is discretely modeled and simplified. Here, it can be assumed that all supports have the same stiffness, and the elastic support coefficient is 1*10 4 N / m changes to 2*10 for approximately rigid support 9 N / m. representing different models i order critical speed, where ,Model B and model C First i order critical speed with respect to the model A No. i critical speed error Expressed as

[0107] (11)

[0108] Figure 4 to Figure 11 When the system rotates in the same direction and the high-voltage rotor is the main excitation, the comparative analysis diagrams of the first four criti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com