Water-cooled reactor with multiple groups of water inlets and outlets

A water-cooled reactor and reactor technology, which is applied in the direction of transformer/inductor cooling, cooling/ventilation/heating transformation, etc., can solve the problems of potential safety hazards, elevation, and inability to achieve cooling effects, so as to reduce potential safety hazards, The effect of avoiding burnout and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

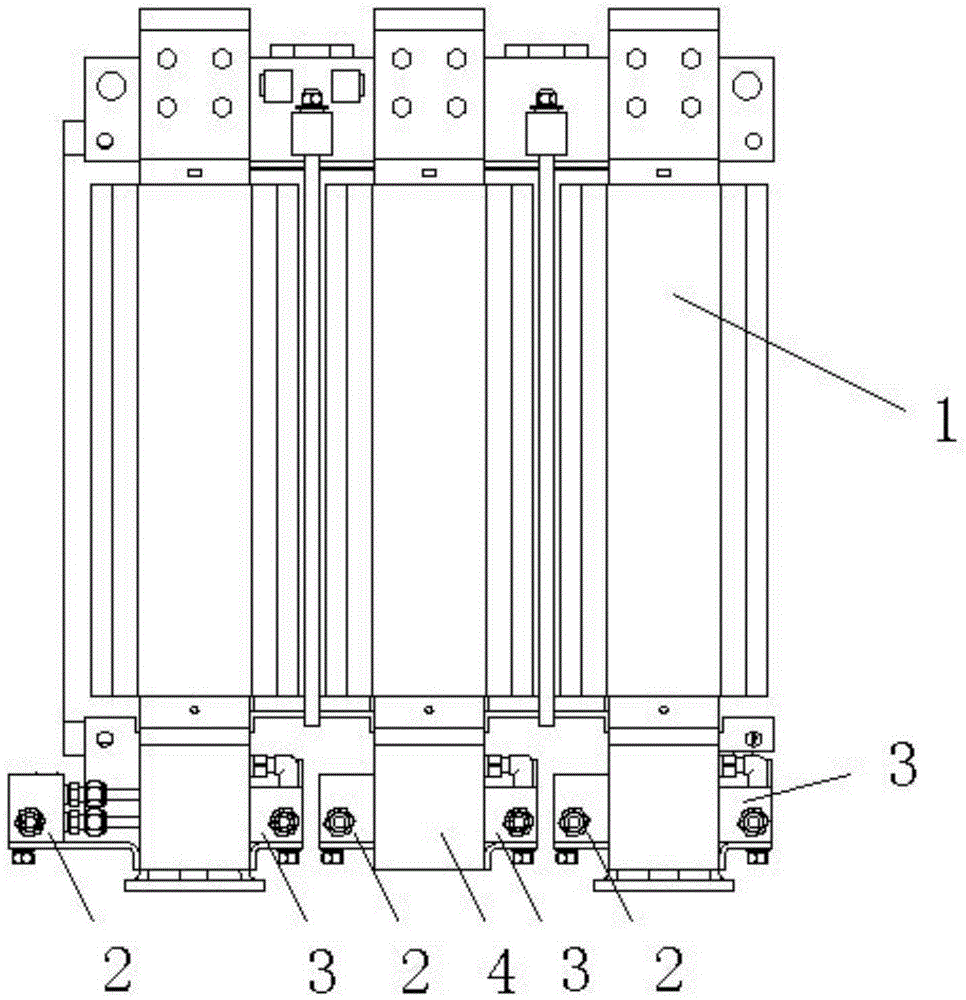

[0012] Such as figure 1 As shown, a water-cooled reactor with multiple sets of water in and out according to the present invention includes multiple sets of water in and out components and a whole composed of a plurality of reactor units 1; each reactor unit 1 corresponds to a group of water in and out components , each group of water inlet and outlet components includes a water inlet 2 and a water outlet 3, and the water inlet 2 and the water outlet 3 are connected through a water-cooling channel, and the water-cooling channel is set in the corresponding reactor unit 1; the bottom of each reactor unit 1 Both sides are provided with brackets 4, and the water inlet 2 and the water outlet 3 are respectively arranged on both sides of the bracket 4.

[0013] The above-mentioned structure also avoids the problem that a plurality of water inlets 2 corresponding to one water outlet 3 designed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap