Fixing fixture for glue barrel of glue dispenser

A technology for fixing fixtures and dispensing machines, which is applied in the field of dispensing machines, can solve problems such as troubles and clogging of rubber cartridges, and achieve the effect of simple structure, convenient disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

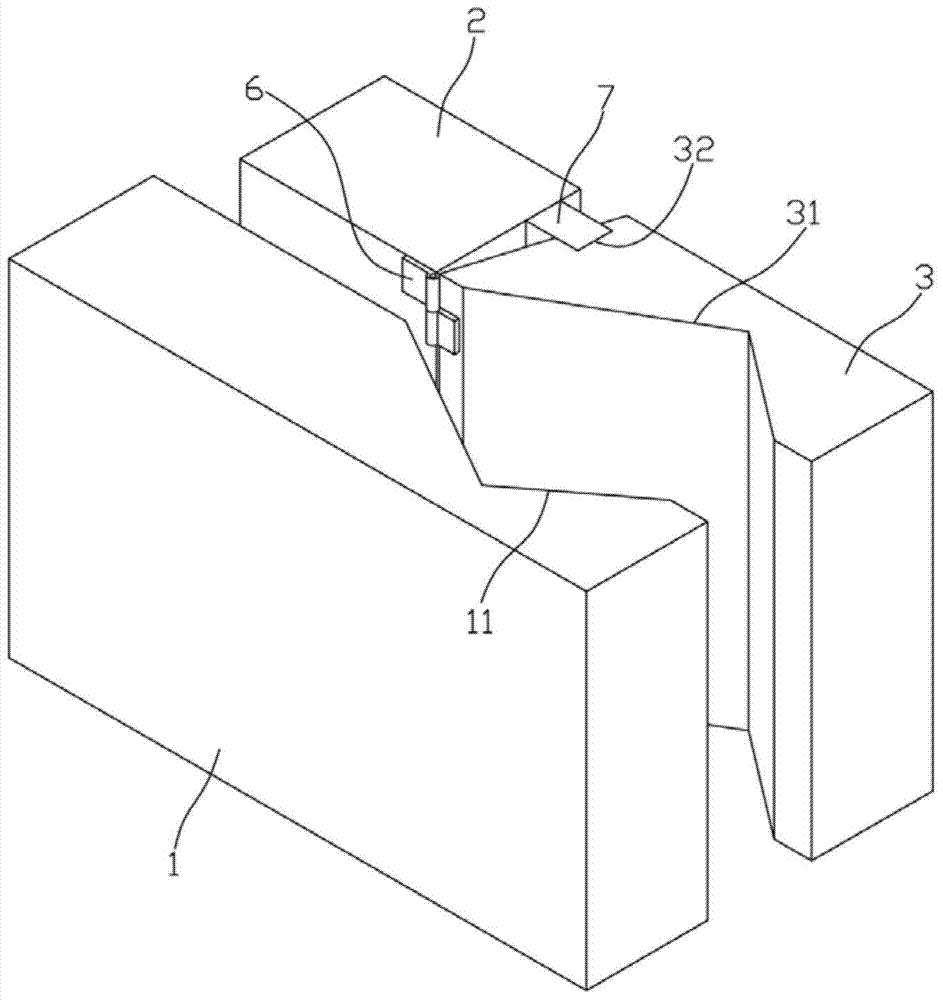

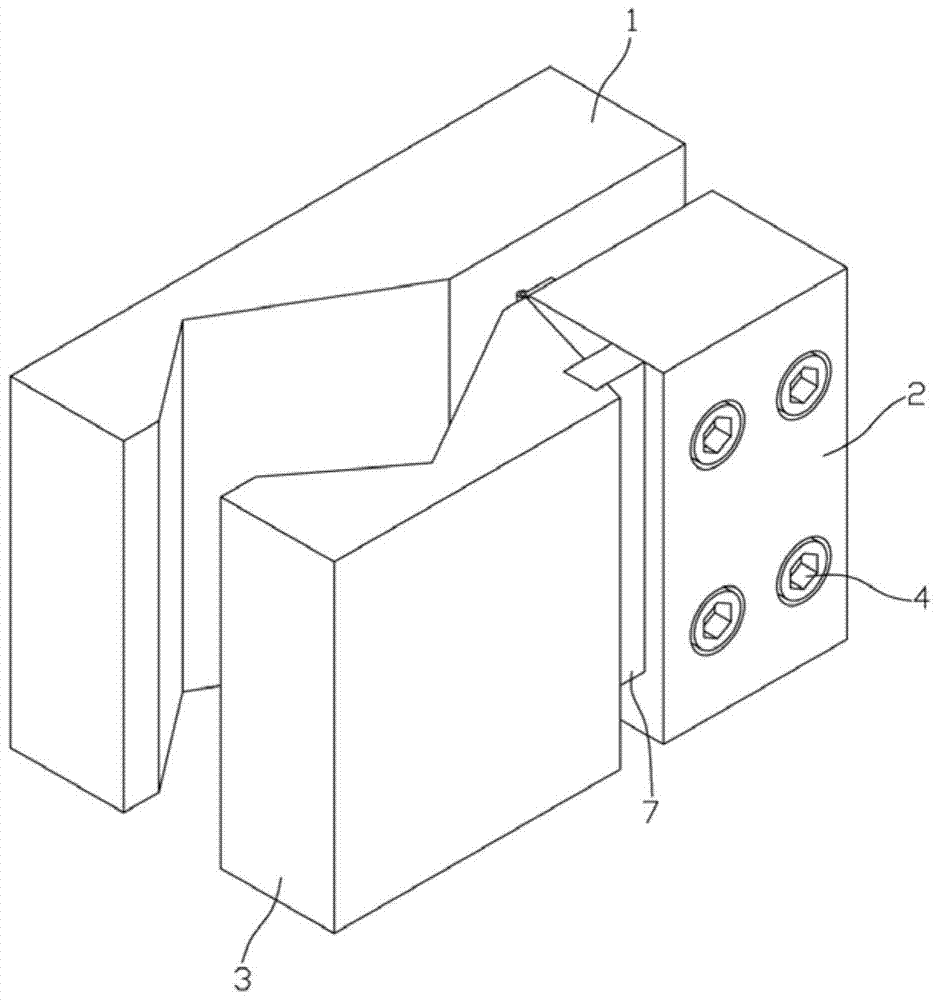

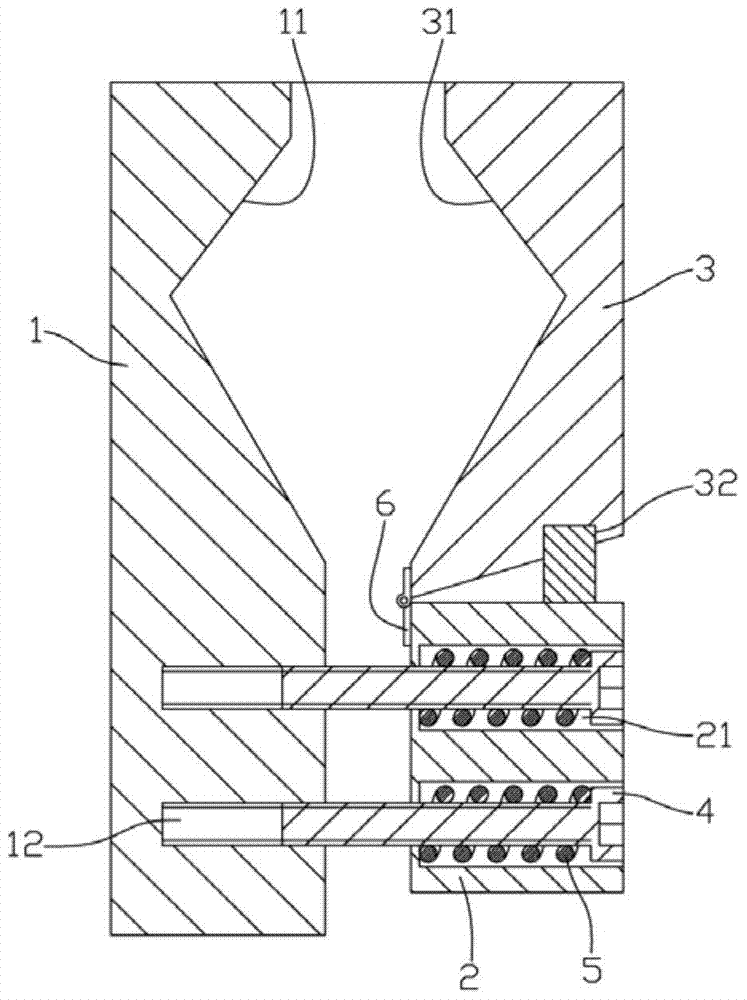

[0020] Example: see Figures 1 to 3 As shown, a fixing fixture for a rubber cartridge of a dispensing machine includes a fixed clamp block 1, a V-shaped first notch 11 is formed on a side wall of the fixed clamp block 1, and a fixed clamp on the same side as the first notch 11 Threaded holes 12 are formed on the side wall of the block 1; several stepped holes 21 are formed on the tension block 2, and bolts 4 are inserted into the stepped holes 21, and the tail ends of the bolts 4 pass through the stepped holes 21 of the tension block 2. Connected in the threaded hole 12 of the fixed clamping block 1, the bolt 4 is inserted with a compression spring 5, and the two ends of the compression spring 5 respectively abut against the head of the bolt 4 and the step of the step hole 21 of the tension block 2 On the surface; the tension block 2 is hinged with the movable clamp block 3 through the hinge 6, and the movable clamp block 3 is formed with a V-shaped second notch 31 opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com