Single-feed conveying support of dispenser

A technology of dispensing machine and feeding conveyor belt, applied in the field of dispensing machine, can solve the problems of high labor intensity, high cost and low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

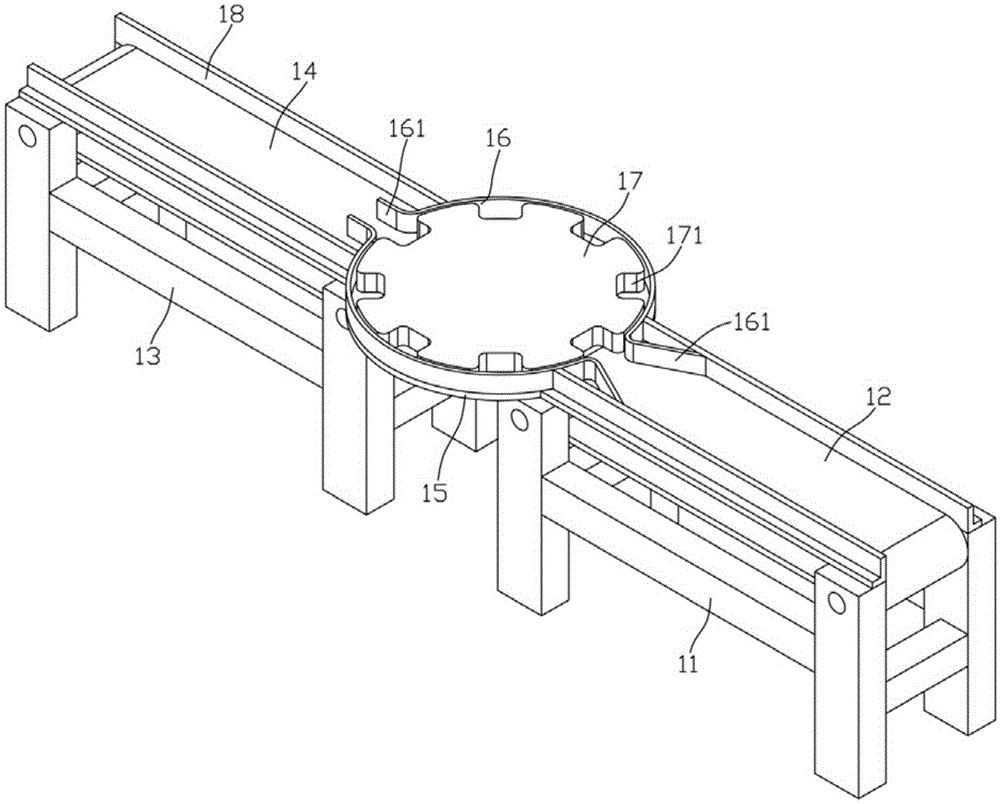

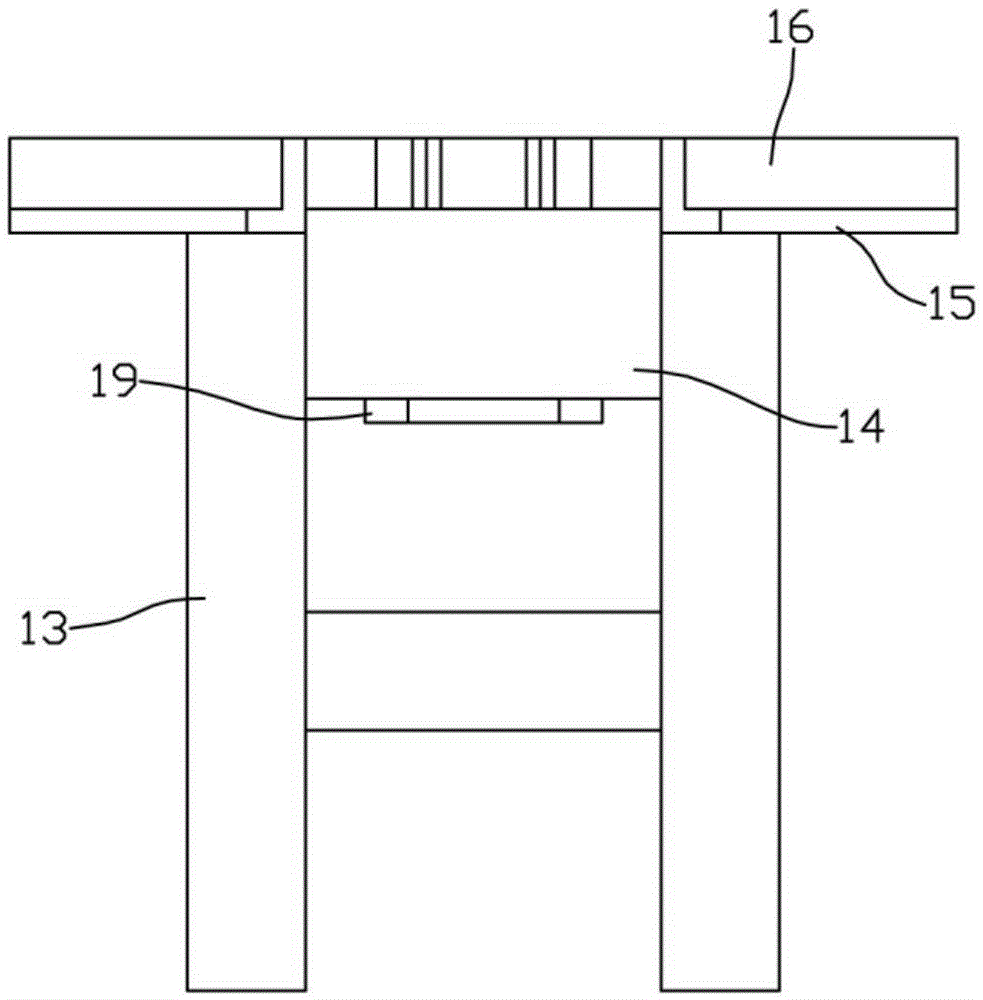

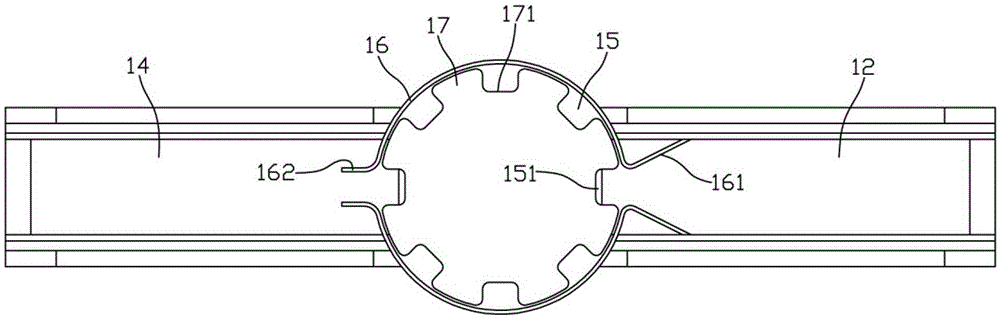

[0015] Example: see Figures 1 to 3 As shown, a single-feed conveying bracket for a glue dispenser includes a first frame 11 and a second frame 12 on the front and rear sides, and the first frame 11 and the second frame 12 are respectively provided with feeding conveyor belts 12 and the discharge conveyor belt 14, the both sides of the feed conveyor belt 12 and the discharge conveyor belt 14 are respectively fixed with a baffle plate 18, and the baffle plate 18 is fixed on the first frame 11 and the second frame 12, the first machine A chassis 15 is provided between the frame 11 and the second frame 12, and the two sides of the chassis 15 are respectively fixed on the rear end of the first frame 11 and the front end of the second frame 12, and the chassis 15 is formed with a feeding conveyor belt 12 and The avoidance notch 151 of the discharge conveyer belt 14 is fixed with two retaining bars 16 respectively on the outer edges of the chassis 15 on both sides of the avoiding no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com