Combined jig for improving manufacturing efficiency of small-sized transformer and method thereof

A technology of combining fixtures and transformers, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems such as the inability of the transformer to be placed in an orderly manner, the accumulation of materials in the dispensing section, and the inefficiency, so as to ensure consistency performance and quality of workmanship, reduce processing time, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

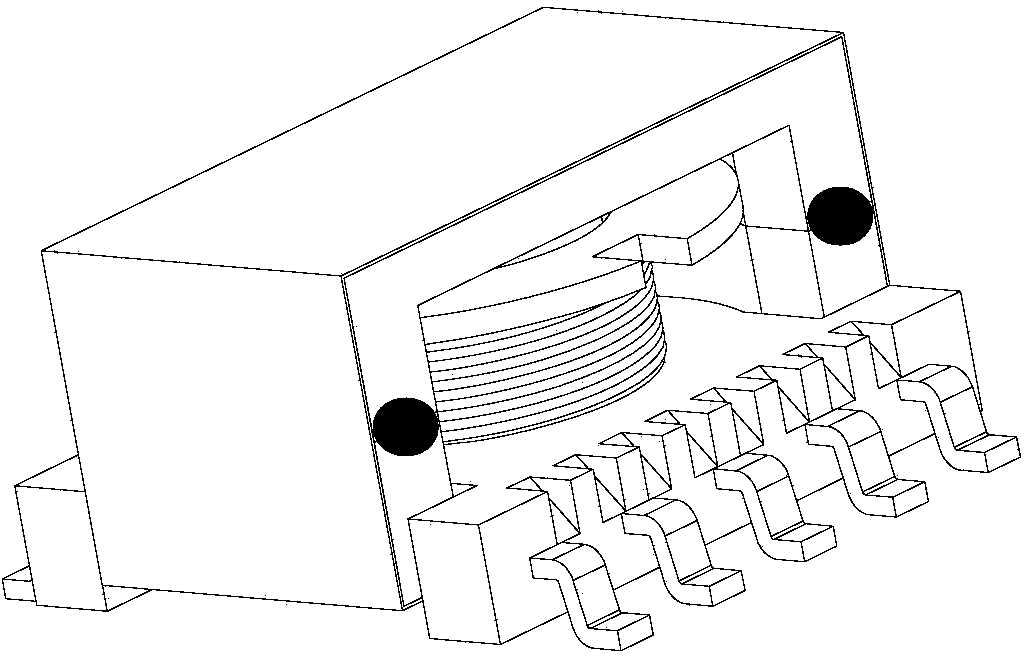

[0073] The combined jig of the present invention will be described in detail below with reference to the schematic diagram.

[0074] Such as Figure 4 , Figure 4a , Figure 5 As shown, the chute plate 20 adopts a rectangular alloy plate with light weight and high strength. There are multiple slides excavated on the front of the slab. Each slide is provided with two slots with different widths and depths. The wider and shallower wide slot 23 is used for the test section to slide into the transformer. The objects are the two rows of pins of the transformer, so the width B of the slot is wider and shallower. The narrower and deeper narrow groove 22 is used to remove the transformer from the back end of the dispensing section. The bearing of the slide is the core surface on the top of the transformer, so its width A is narrow and deep; the narrow groove 22 is located in the wide groove 23 intermediate.

[0075] In order to slide into the transformer conveniently, one end of each sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com