Machine and gate integrated gate

A one-type, machine door technology, applied in the field of lifting gates, can solve the problems of high cost of bottom pivoting flap doors, heavy civil engineering workload, difficult maintenance of rotating shafts, etc., and achieves convenient opening and closing of gates, less auxiliary buildings, and low maintenance convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

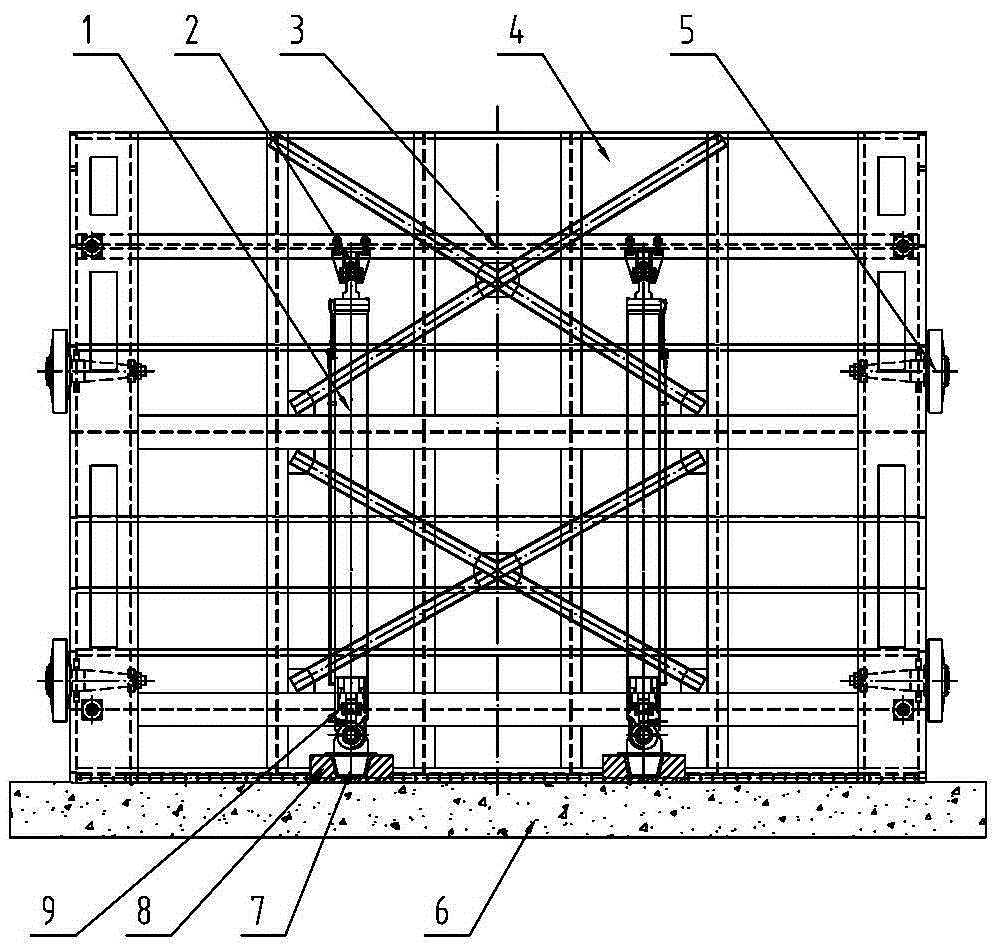

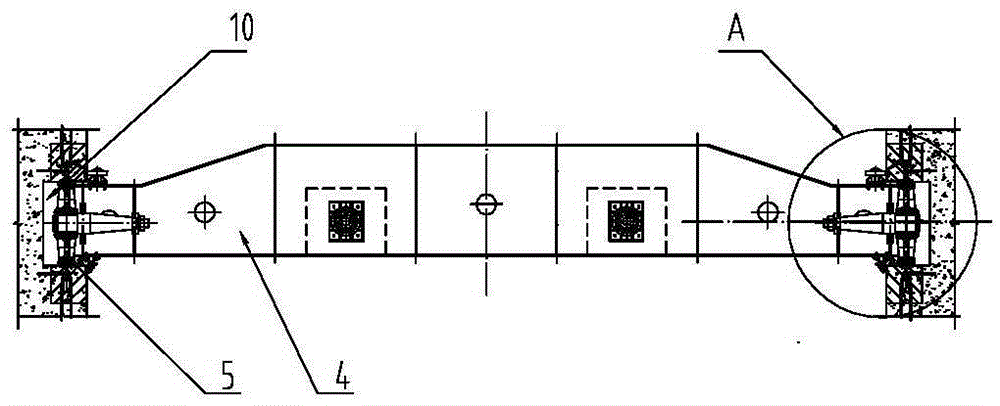

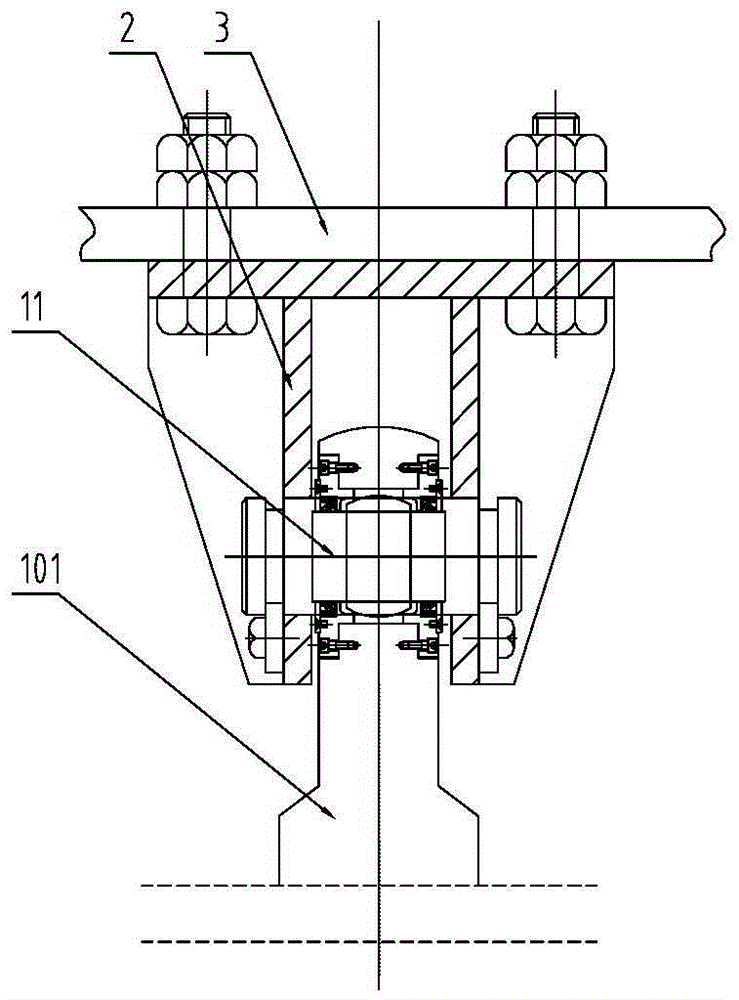

[0016] Such as Figure 1-5 As shown, it is a machine-door integrated gate, which includes a door body 4 blocked on the river, a bottom sill 6 is provided under the door body 4, door grooves 10 are provided on both sides of the door body 4, and a door groove 10 is provided on the backwater side of the door body 4. There is a crossbeam 3, and a hydraulic cylinder 1 is vertically arranged under the crossbeam 3, and two hydraulic cylinders 1 are arranged symmetrically on the backwater side of the door body 4. The piston rod 101 of the hydraulic cylinder 1 protrudes from the upper end of the hydraulic cylinder 1, and the hydraulic cylinder 1 The upper end of the piston rod 101 is connected with the fixed support 2 on the lower side of the beam 3 through the upper pin shaft 11, the lower end of the cylinder body 102 of the hydraulic cylinder 1 is connected with the movable support 9 through the lower pin shaft 12, and the lower end of the movable support 9 is provided with The taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com