Stem Seal

A technology of sealing device and valve stem, which is applied in valve device, shaft seal, valve details, etc., to achieve the effects of reducing wear, reducing sealing force, and simple and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

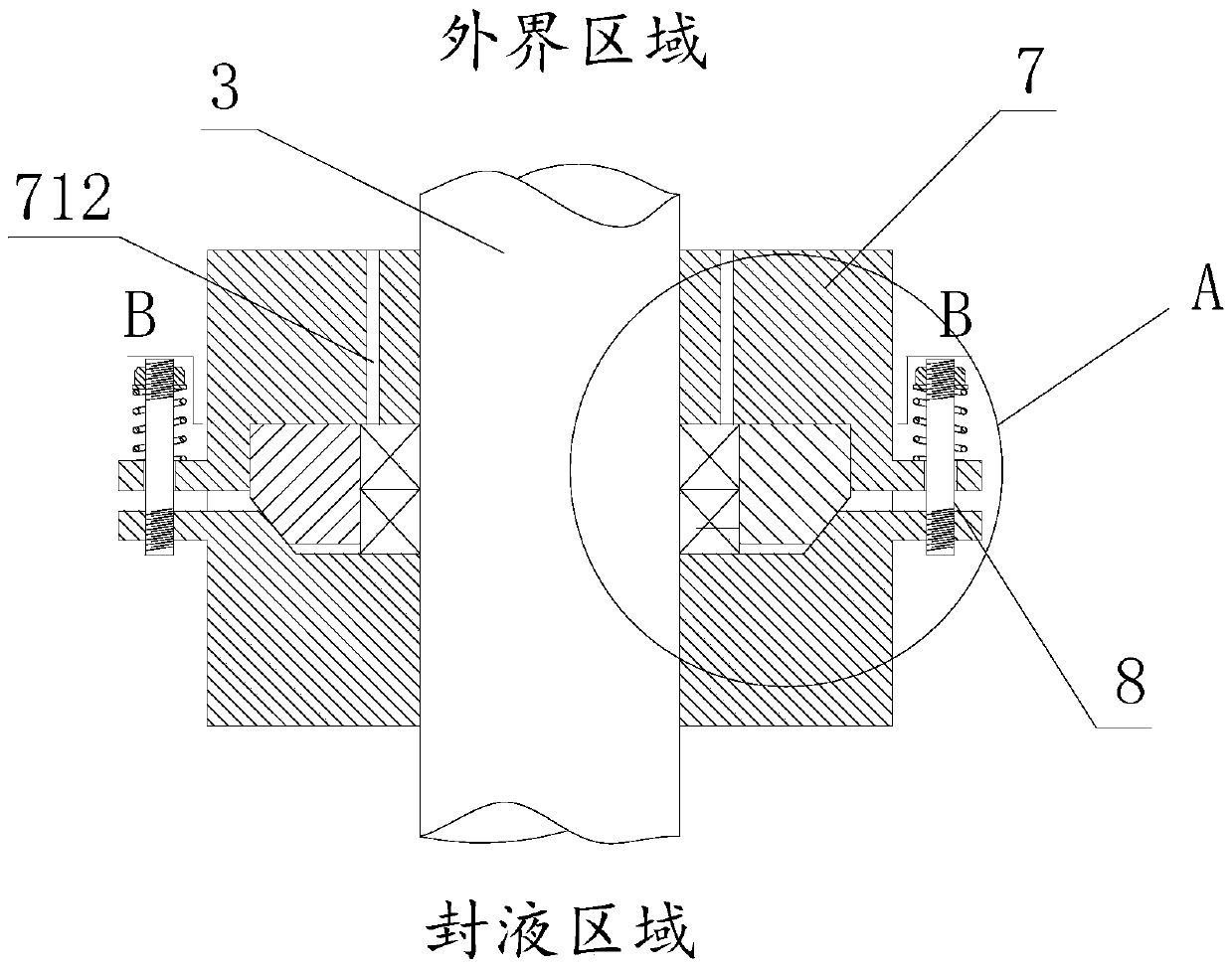

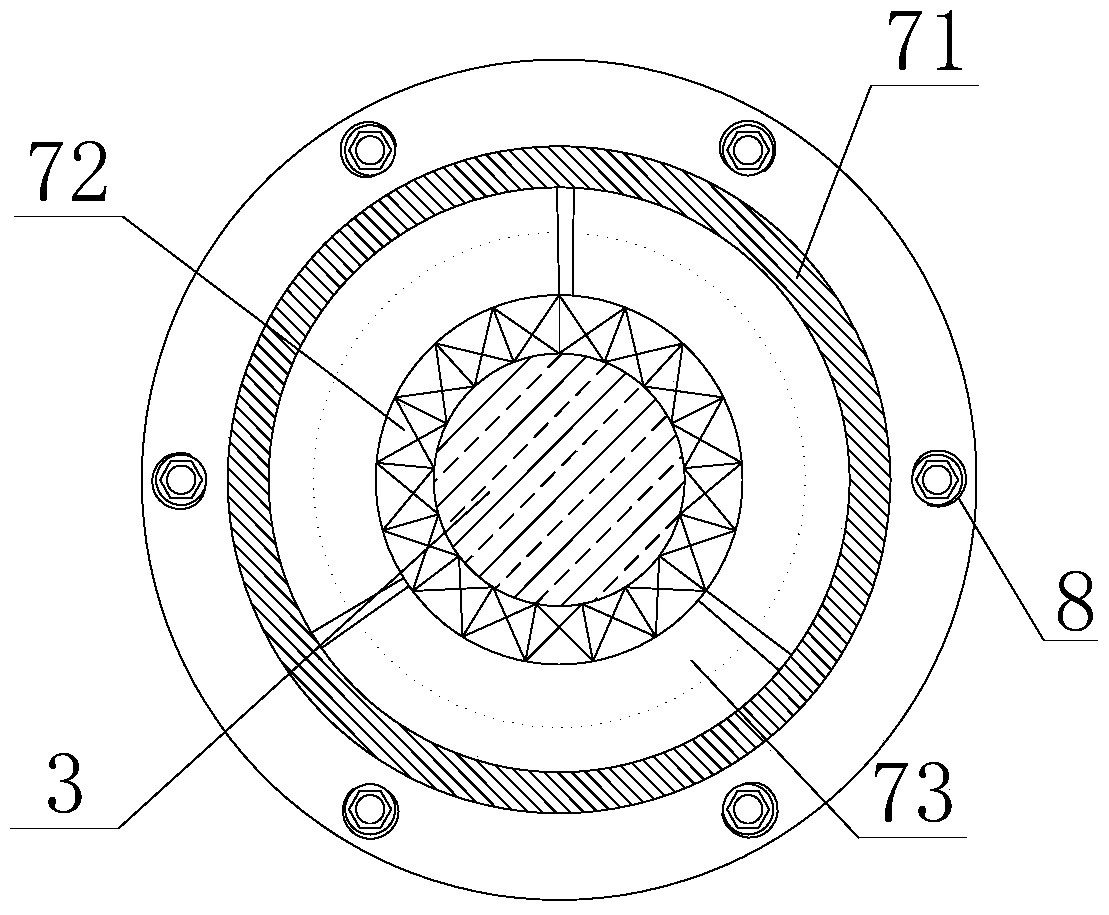

[0019] Such as Figures 1 to 4 A valve stem sealing device is shown, the valve stem sealing device is mainly aimed at the valve stem 3 having a circular cross-section, and the valve stem 3 needs to be rotated and moved axially during operation.

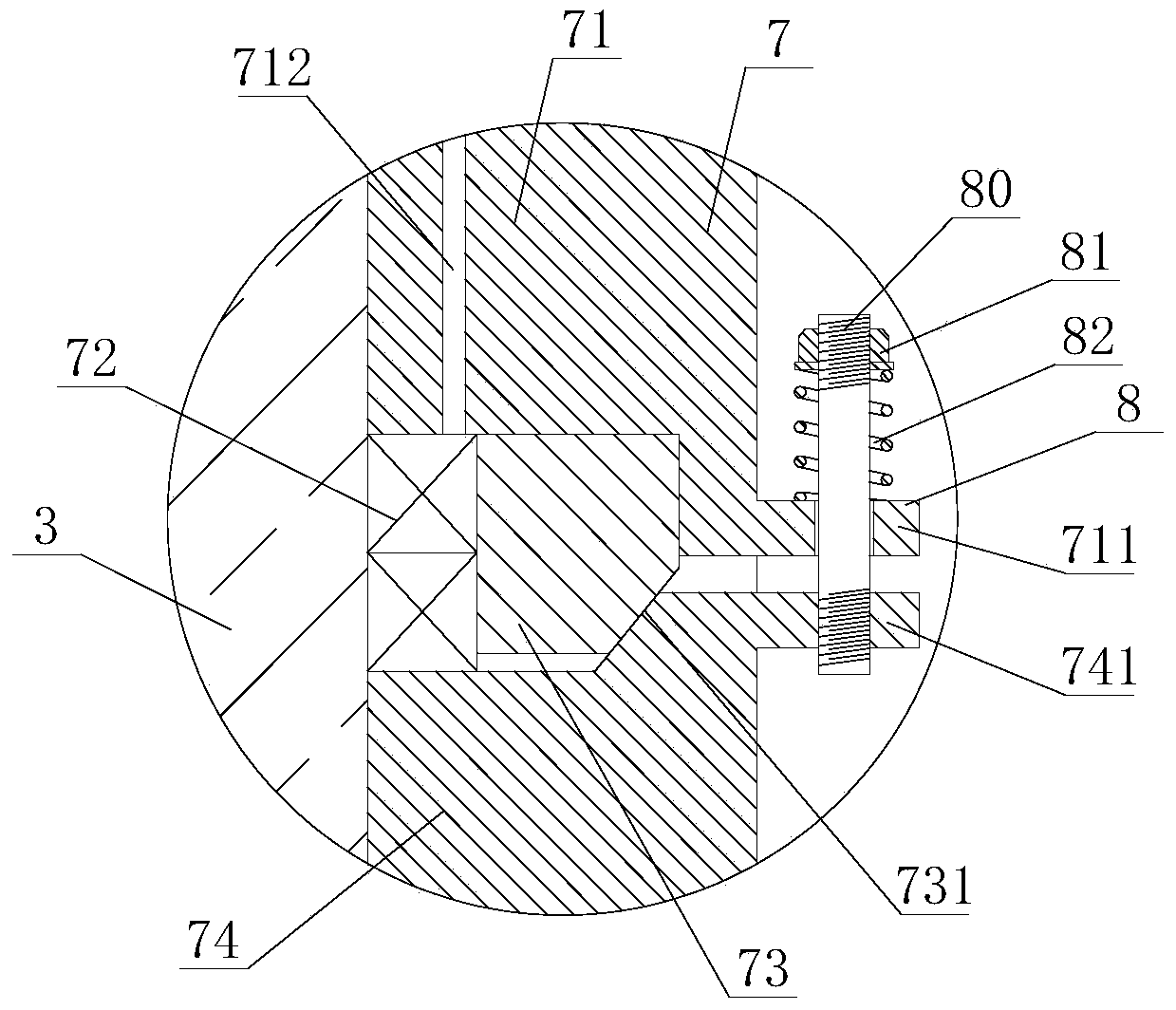

[0020] The sealing device for the valve stem includes a sleeve 7 sleeved on the outside of the valve stem, a packing 72 for sealing the valve stem, a pressing piece 73 for pressing the packing, and a pressing mechanism 8 . And the sleeve 7 includes an upper sleeve 71 and a lower sleeve 74 . Both the filler 72 and the pressure piece 73 are located between the upper sleeve 71 and the lower sleeve 74 , and since the valve stem 3 is a polished rod with a circular cross section, the filler 72 also forms a ring and is located outside the valve stem 3 . The inner side of the pressing piece 73 is against the outer periphery of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com