An Efficient Sorting Method Based on Tire Sorting

A sorting method and tire technology, applied in the sorting field, can solve the problems of affecting the company's inventory, prone to errors, low efficiency, etc., to achieve the effect of improving accurate time, improving efficiency, and reducing production errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

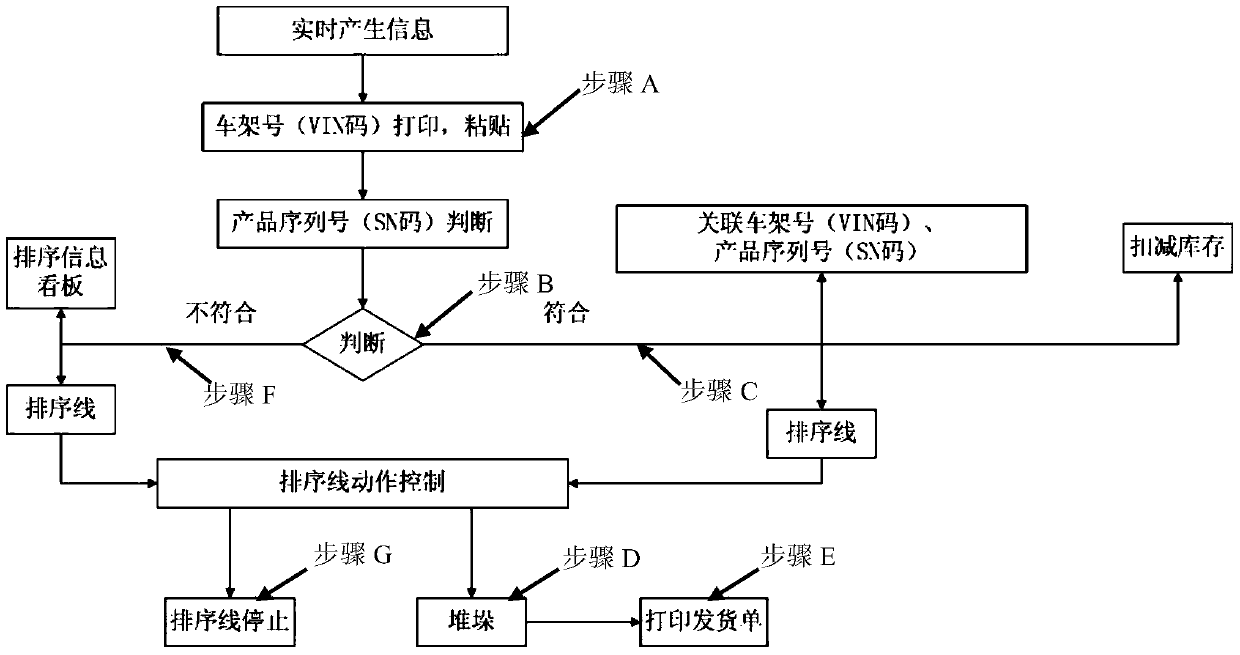

[0020] figure 1 It is a flowchart of an efficient sorting method based on tire sorting in an embodiment of the present invention.

[0021] Such as figure 1 As shown, an efficient sorting method based on tire sorting has the following steps:

[0022] Step A: Print the vehicle chassis number (VIN code) according to the real-time production information of the vehicle manufacturer, and paste it on the corresponding vehicle, and proceed to step B.

[0023] Step B, judging whether the product serial number (SN code) on the tire meets the requirements, if it meets the requirements, go to step C, if not, go to step F.

[0024] Step C: Associating the vehicle frame number (VIN code) with the product serial number (SN code), deducting the inventory, the sorting line information board displays "Passed", and at the same time, the programmable logic controller (PLC) controls the action of the sorting line, and enters the step d.

[0025] Step D: The programmable logic controller (PLC) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com