Monitoring conversion control system

A conversion control and conversion system technology, applied in the field of conversion systems, can solve the problems of plastic packaging equipment not supporting the SECS international standard protocol, equipment unable to access the automatic control system, affecting equipment production capacity and product quality, etc. The effect of fast and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

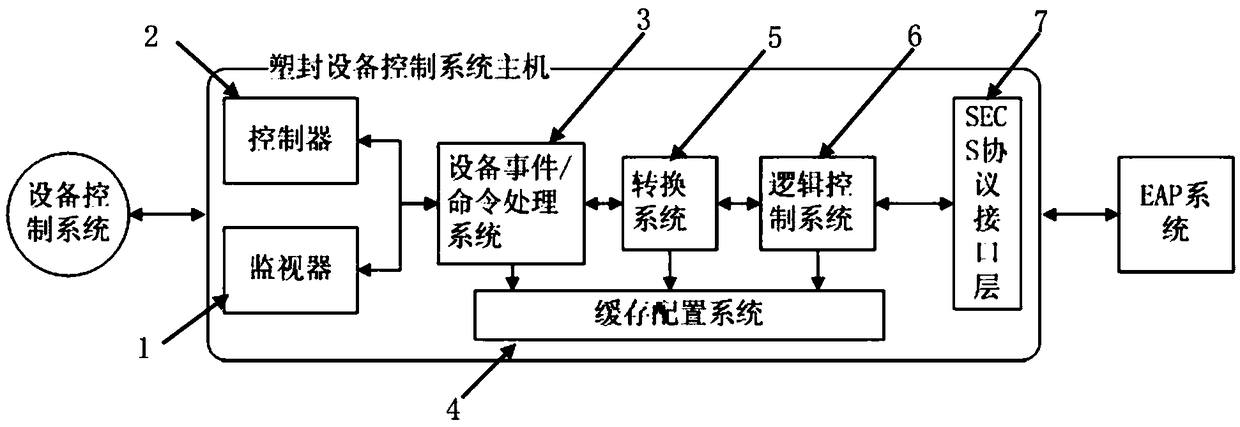

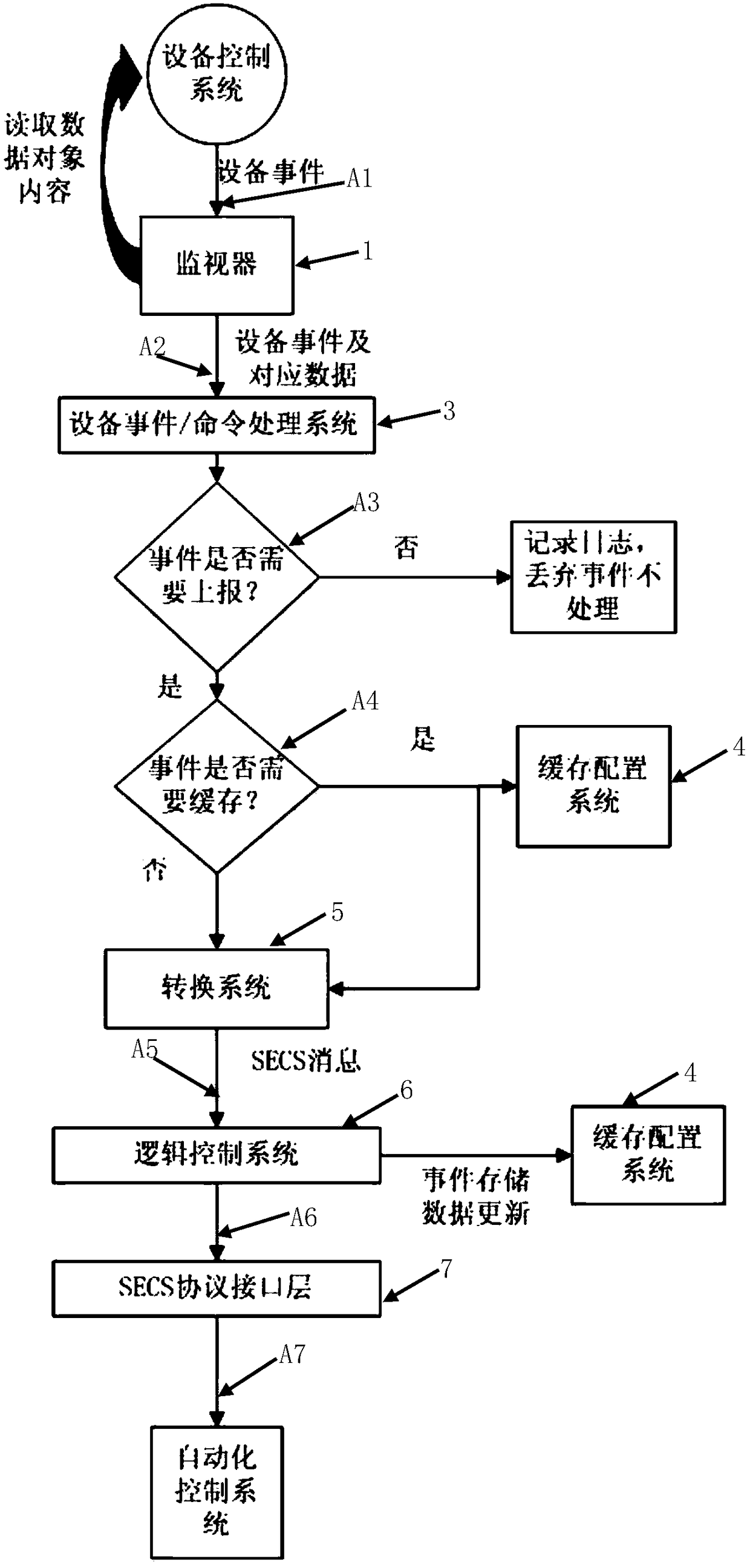

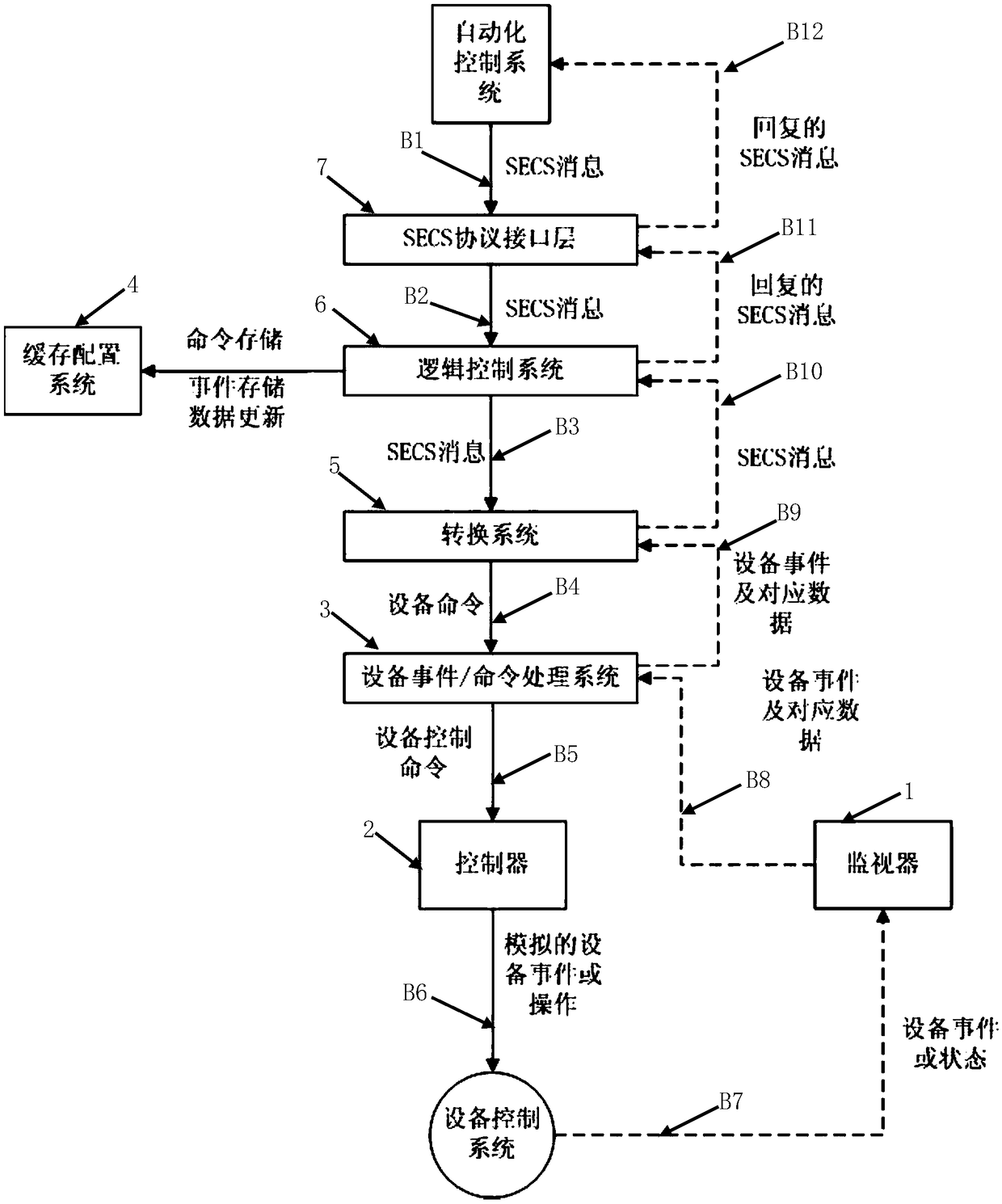

[0053] figure 1 It is a structural block diagram of the monitoring conversion control system in the embodiment of the present invention.

[0054] Such as figure 1 As shown, the monitoring conversion control system has: a monitor 1, a controller 2, a device event / command processing system 3, a buffer configuration system 4, a conversion system 5, a logic control system 6 and a SECS protocol interface layer 7.

[0055] The monitoring conversion control system is connected between the equipment control system and the automation control system, so that the equipment control system can be connected with the automation control system to ensure normal communication.

[0056] Monitor 1 monitors events, operations, and data objects of the equipment control system.

[0057] The controller 2 converts the control commands into corresponding operations or events of the equipment control system, and sends them to the equipment control system.

[0058] The equipment event / command processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com