Non-slip branch shearing device for cuttage

A shearing device and branch technology, applied in the field of agriculture and forestry, can solve the problems of misplacement of the predetermined cutting position of the branches, difficulty in forming a cutting and forming part, low efficiency, etc., and achieve the effects of simple and stable device structure, high-efficiency shearing and forming, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

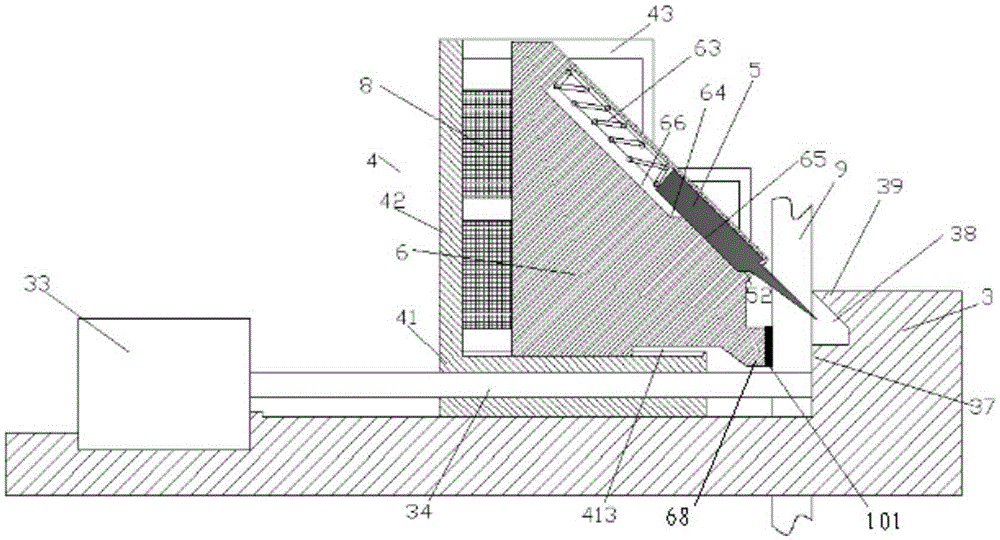

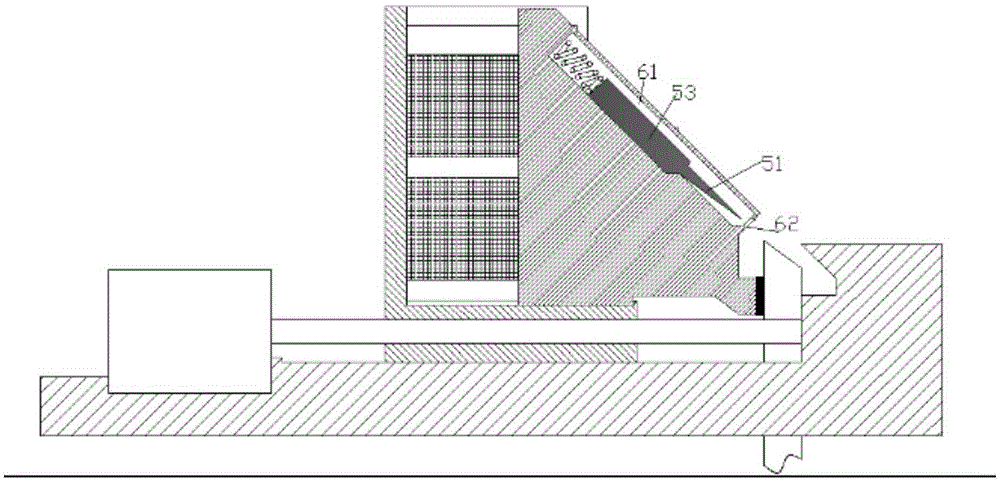

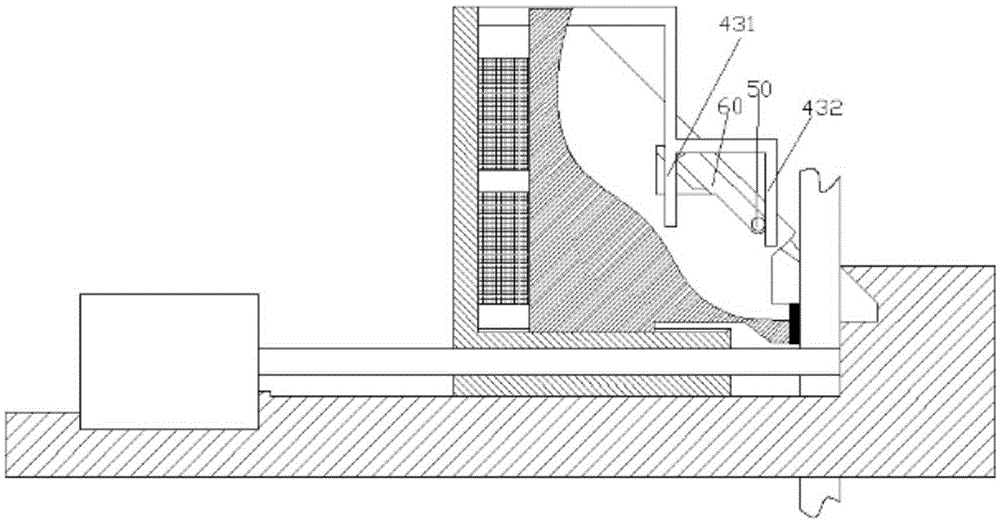

[0013] Combine below Figure 1-4 The present invention will be described in detail.

[0014] According to an embodiment, a non-slip branch cutting device for cuttings includes a frame 3, a sliding frame that can slide on the frame 3 driven by a motor 33 fixedly installed on the frame 3 through a screw 34 4 and the clamping ramp block 6 installed on the sliding frame 4, wherein the sliding frame 4 includes a horizontal part 41 threadedly fitted with the screw rod 34, and a vertical part 42 fixedly connected with the horizontal part 41 And the toggle portion 43 fixedly connected to the vertical portion 42 at the front and rear sides of the clamping ramp block 6, wherein the bottom of the clamping ramp block 6 is slidably mounted on the horizontal portion In the chute 413 on the upper side of 41, a compression elastic part 8 is provided between the vertical part 42 and the left side of the clamping ramp block 6 to place the clamping ramp block 6 on the The chute 413 is biased t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com