Solar energy electricity supply type punching device for punching multiple holes in thin plate and using method of solar energy electricity supply type punching device

A technology of solar power supply and punching device, applied in the field of punching equipment, can solve the problems of increasing the overall weight of the punch, delaying the action of lifting the punch, and reducing the control response, so as to achieve a stable device structure, convenient use, and improved response. The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

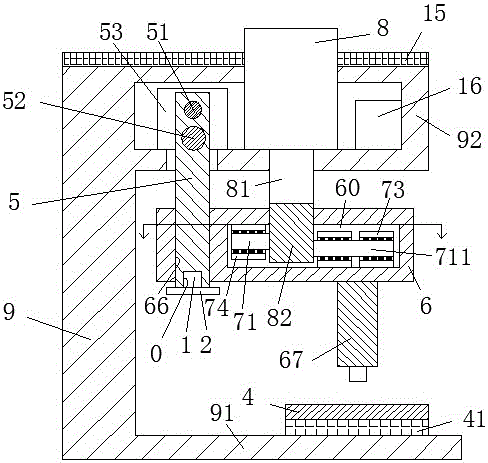

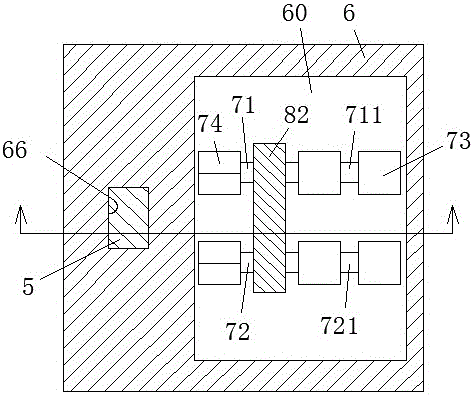

[0009] Combine below Figure 1-2 The present invention will be described in detail.

[0010] According to an embodiment of the present invention, a solar-powered punching device for punching thin plates with multiple holes is used for punching a plurality of punching holes on a thin plate 4, including a fixed device for carrying the thin plate 4 and a punching liner 41 The workbench 91 and the frame 9 of the upper installation box 92 are fixedly installed with the punching lifting drive device 8 comprising the telescopic rod 81 in the upper installation cabinet 92, and the lower end of the telescopic rod 81 is connected with the front and rear sliding guide blocks. 82 is fixedly connected, the front and rear pressing rollers 72 and the rear pressing rollers 71 of the front and rear pressing rollers 74 are rotatably separated from the front and rear directions on the left side of the lower part of the front and rear sliding guide blocks 82. , the right side of the lower part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com