Sticky candy special-purpose boiling stirrer

A technology of blender and kraft candy, applied in confectionery, application, confectionery industry, etc., can solve the problems of labor-intensive, different taste of kraft candy, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

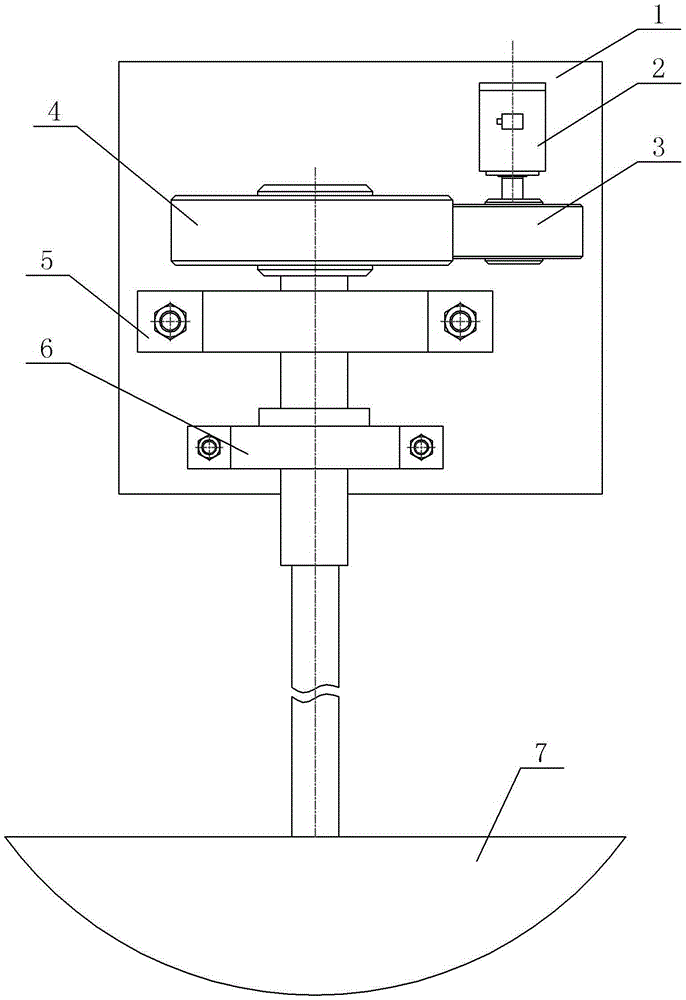

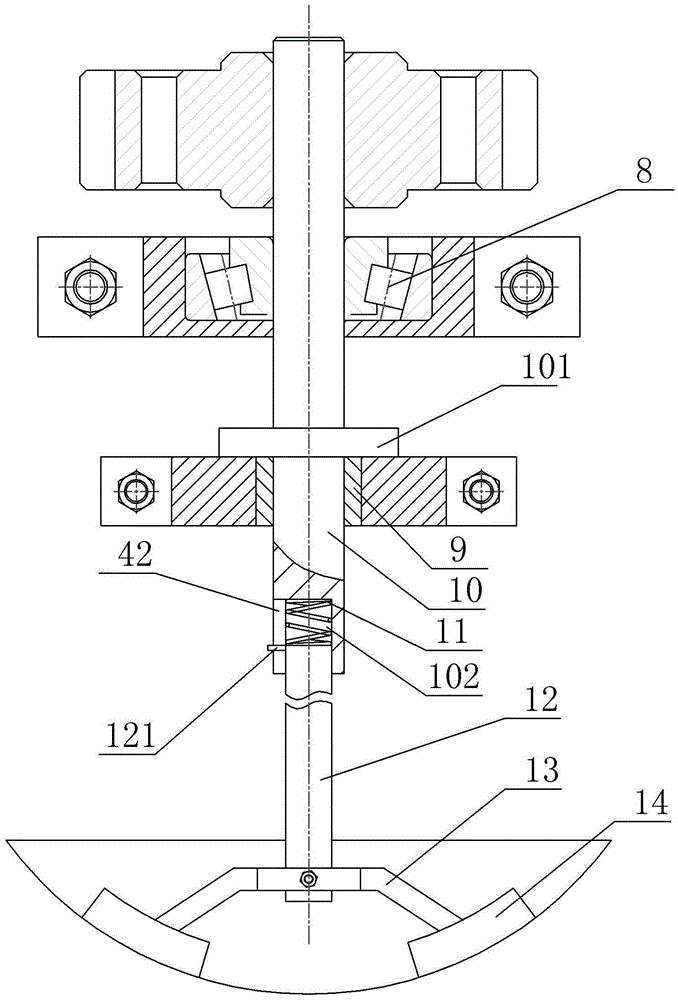

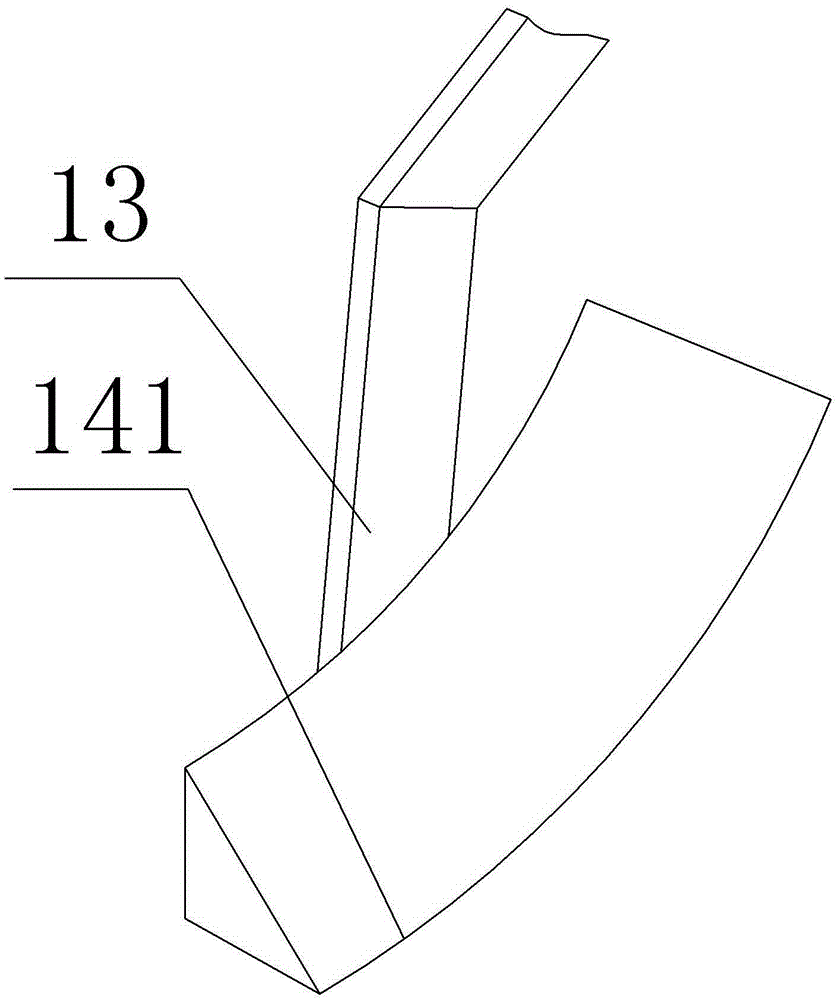

[0017] Such as figure 1 and figure 2 The shown kraft candy cooking special mixer includes a frame 1, a power unit, a stirring device, and a cooking pot 7. The power unit includes a motor 2 and a driving gear 3. The motor 2 is fixedly installed on the frame 1, and the driving gear 3 is fixed. Installed on the output shaft of the motor 2. The stirring device includes a driven gear 4, a bearing seat 5, a support seat 6, a bearing 8, a copper sleeve 9, a drive shaft 10, a compression spring 11, a stirring rod 12, a support 13, and a stirring block 14, such as figure 1 and figure 2 As shown, the drive shaft 10 is sequentially installed with a driven gear 4, a bearing 8, and a copper sleeve 9 from top to bottom. The driven gear 4 meshes with the driving gear 3 and is fixedly installed on the upper end of the drive shaft 10 , the bearing 8 is sleeved on the drive shaft 10 and fixedly installed in the bearing seat 5 , and the bearing seat 5 is fixedly installed on the frame 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com