Pose identification method of arc sensing welding gun

An identification method and arc sensing technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of limited pose information, difficult to meet, insufficient identification, etc., and achieve the effect of avoiding aliasing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

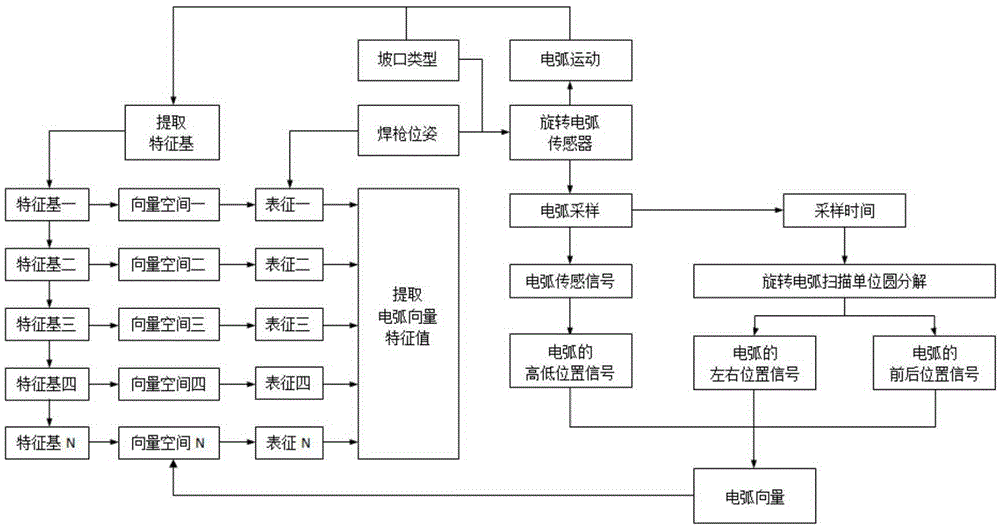

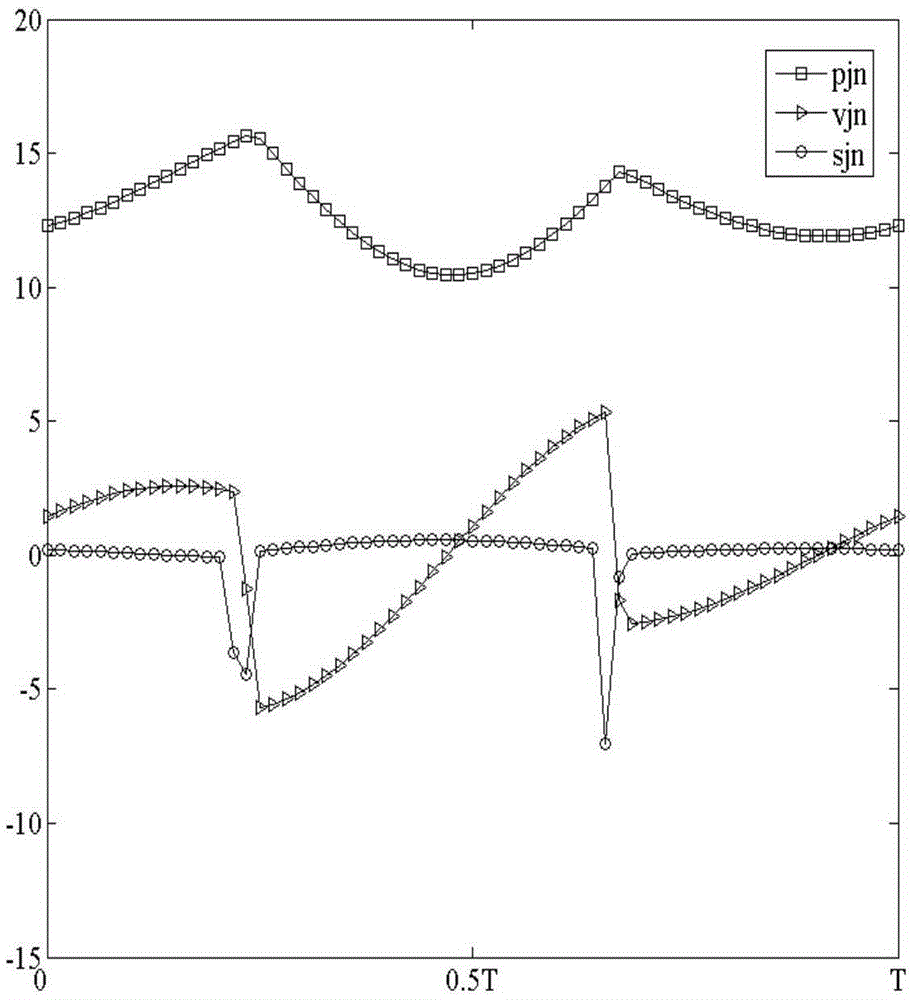

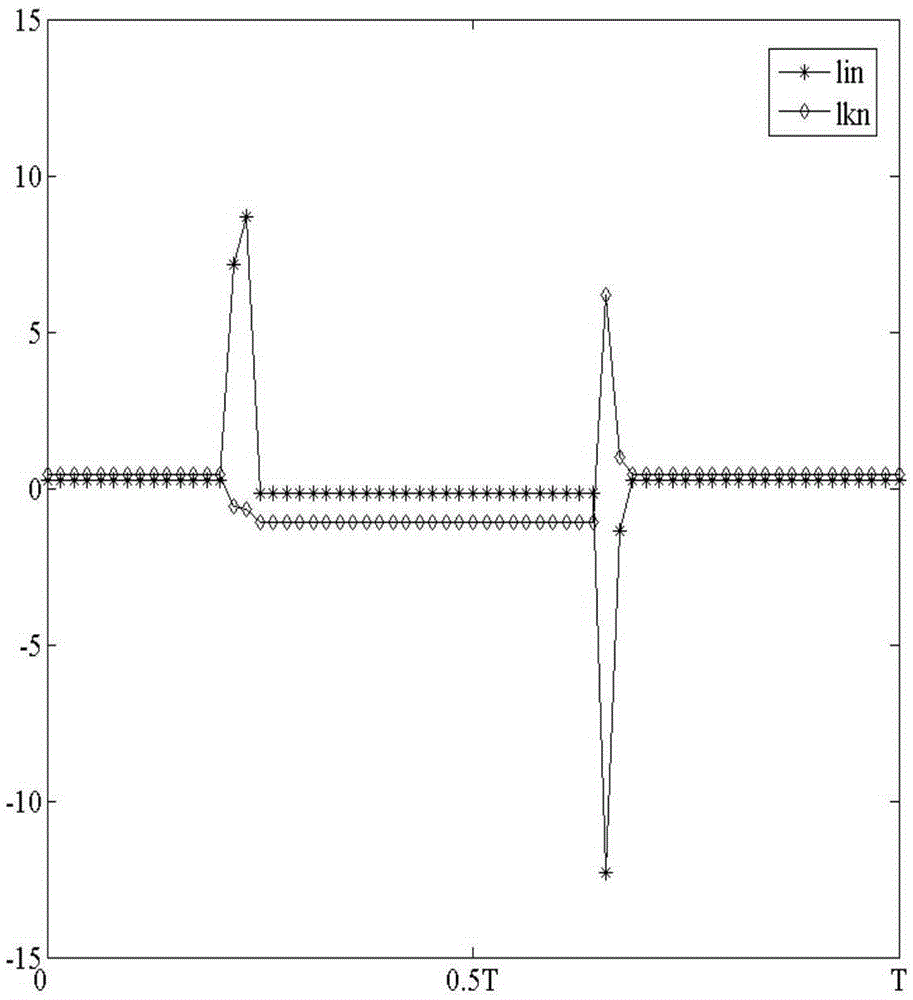

[0016] see figure 1 , the present embodiment adopts the rotary arc sensor to weld the V-groove weld, and the arc sampling is carried out by the rotary arc sensor during welding, and the arc sensing signal I is obtained by sampling. n (n=1,2...N, N is the total sampling number of a sampling period), due to the arc sampling signal I n It not only includes the bevel type and welding torch posture during welding, but also represents the distance between the welding torch and the workpiece at each sampling time, so the arc sampling signal I n Converted to the high and low position signal y of the arc in turn n (n=1,2...N).

[0017] The arc scanning time of the rotating arc sensor is T, and the time signal of each arc sampling is t n (n=1,2...N), will sample the time signal t n Decompose the unit circle by scanning the rotating arc, and decompose it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com