Tire installation device and method using electric control

An installation device and tire technology, which is applied in the directions of tire installation, tire parts, transportation and packaging, can solve the problems of time-consuming and laborious installation methods, tire maintenance, and high personnel, so as to reduce labor intensity, improve installation efficiency, and save labor. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

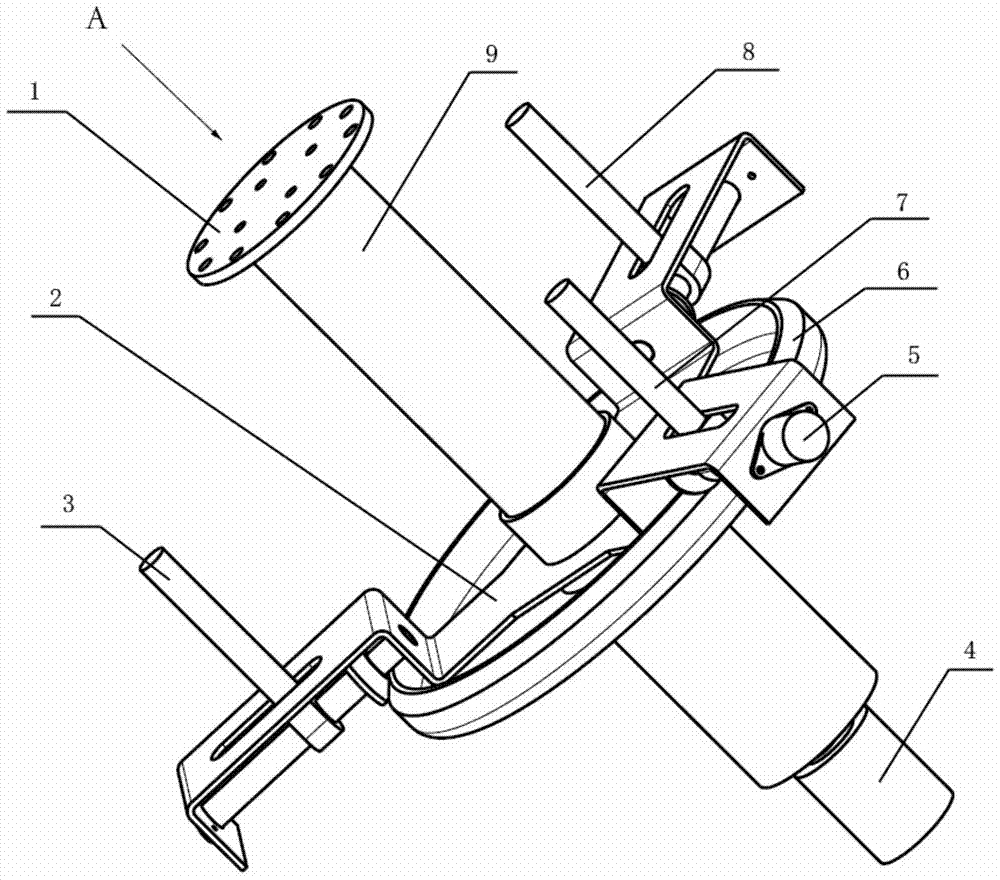

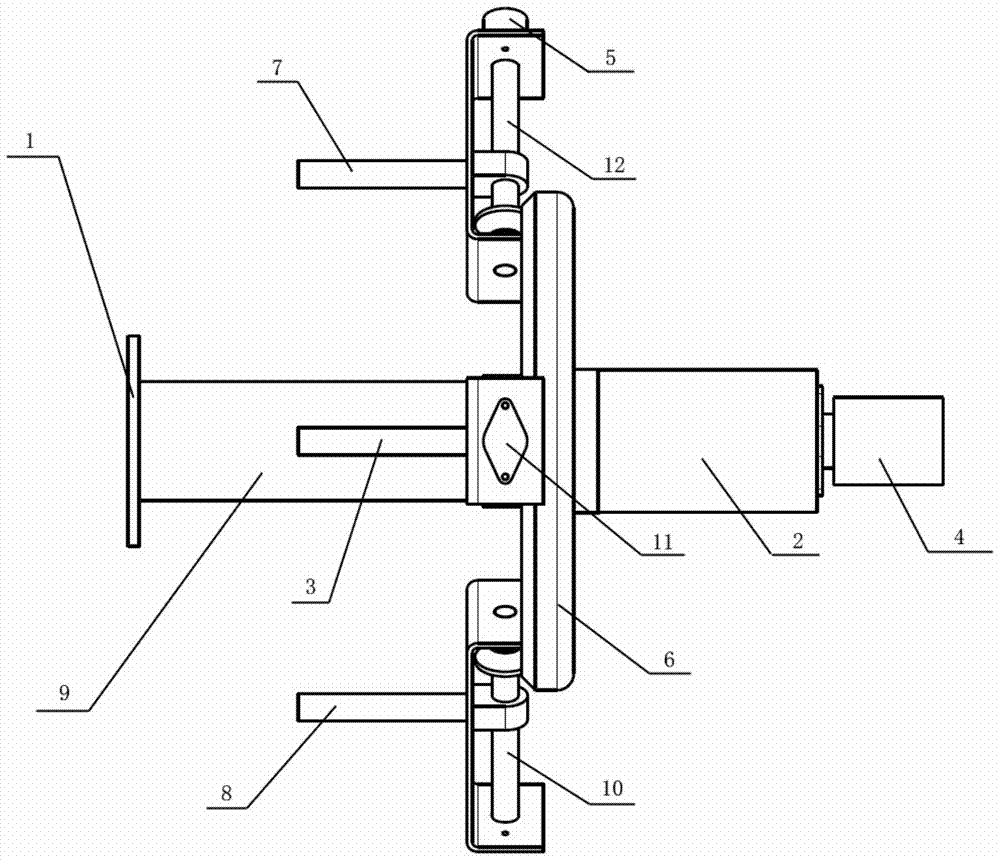

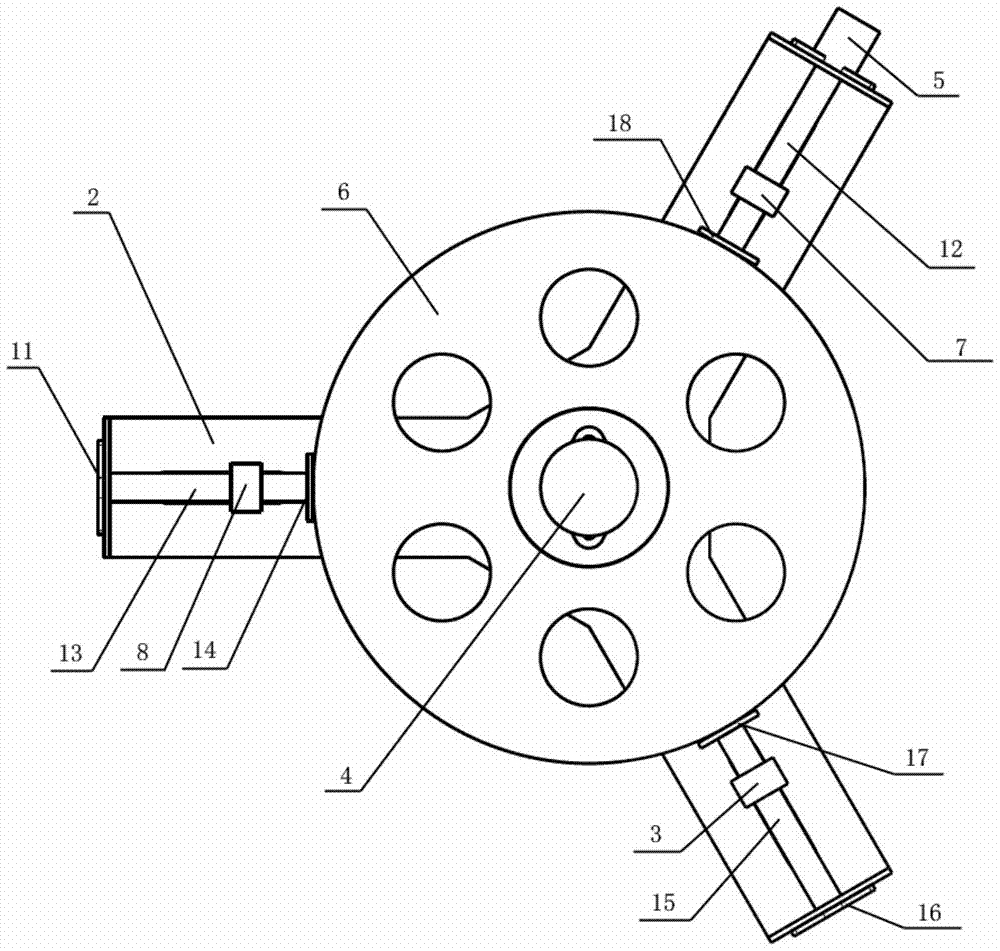

[0033] combine Figure 1 to Figure 7 , a tire installation device, which includes: a mounting plate 1, a fixed base 2, a first positioning rod 3, a first motor 4, a second motor 5, a large vertebral gear 6, a second positioning rod 7, a third positioning rod 8, and a lifting rod 9. The first screw 10, the first stopper 11, the second screw 12, the third screw 13, the first small vertebral gear 14, the second screw 15, the second stopper 16, the second small vertebral gear 17, the third small vertebral gear 18.

[0034] Concrete connection relationship is: the first screw mandrel 10, the second screw mandrel 12, the 3rd screw mandrel 13 are installed on the positioning holes at the two ends of the C-shaped limit of the fixed base 2, the first positioning rod 3, the second positioning rod 7, the first positioning rod Three positioning rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com