Bicycle chain wheel manufacturing method

A manufacturing method and technology of sprocket sets, which are applied to belts/chains/gears, gear teeth, vehicle parts, etc., can solve the problems of failure to achieve light weight, time-consuming and troublesome manufacturing and assembly of rear sprocket sets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

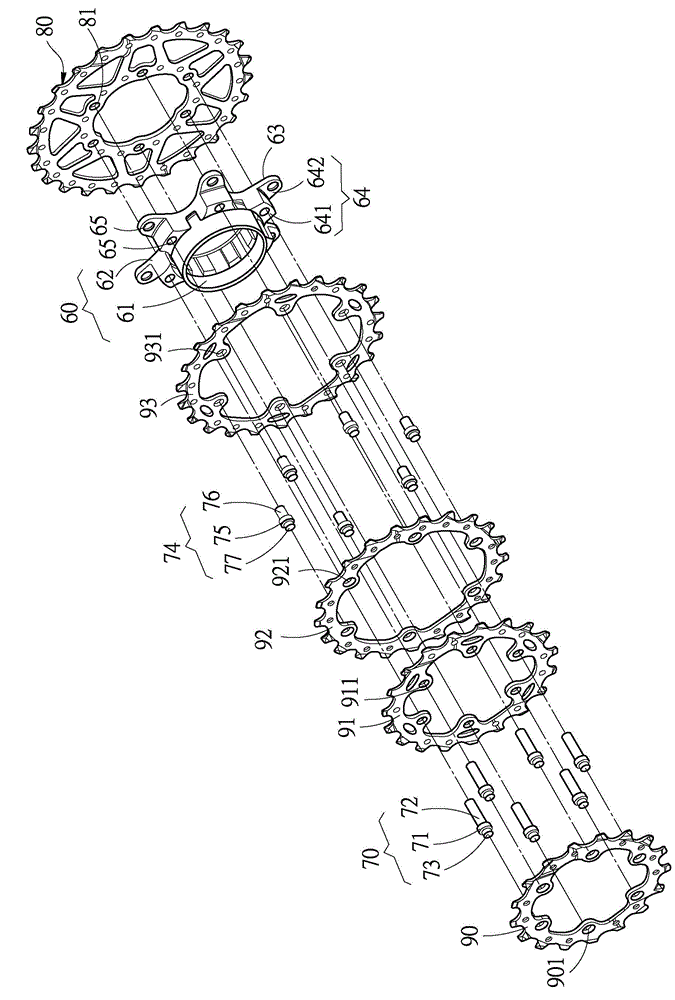

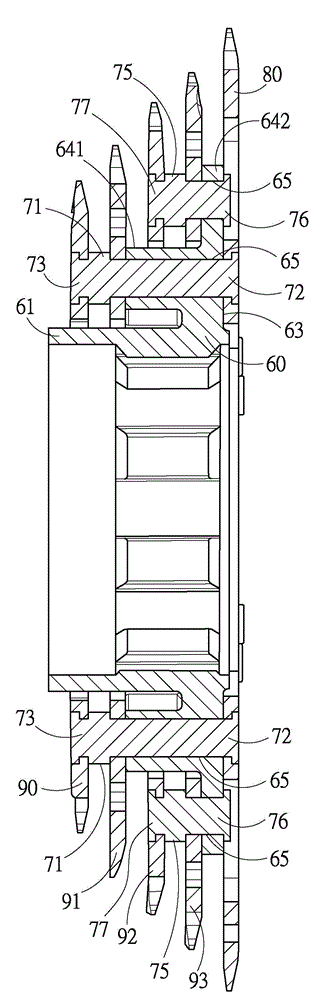

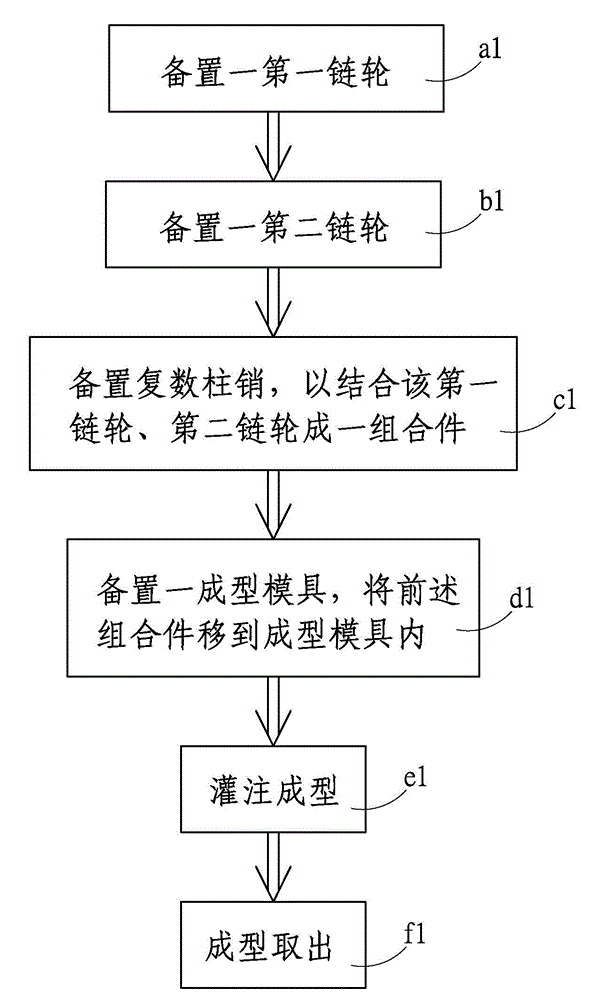

[0058] see Figure 3~Figure 6 , the present invention discloses a method for manufacturing a bicycle sprocket set, the first embodiment of which includes the following steps:

[0059] Step (a1): First prepare a first sprocket 10, the first sprocket 10 has a first outer ring portion 11 and a first inner ring portion 12, the first outer ring portion 11 is provided with a plurality of first sprockets 13, and the first inner ring part 12 is provided with a plurality of first male connectors 14, in this embodiment the plurality of first male connectors 14 are arranged equidistantly on the first inner ring part 12, and the first male connectors 14 A first positioning hole 15 is provided.

[0060] Step (b1): prepare a second sprocket 20, the second sprocket 20 is smaller than the first sprocket 10 and has a second outer ring part 21 and a second inner ring part 22, the second outer ring part 21 is set There are a plurality of second chain teeth 23, and the second inner ring portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com