Sliding joints based on spherical plain bearings

A joint bearing and sliding technology, which is applied in the direction of building components, earthquake resistance, construction, etc., can solve the problems of steel structure damage, failure to realize vertical and horizontal sliding, and internal stress of steel structure cannot be released, so as to ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

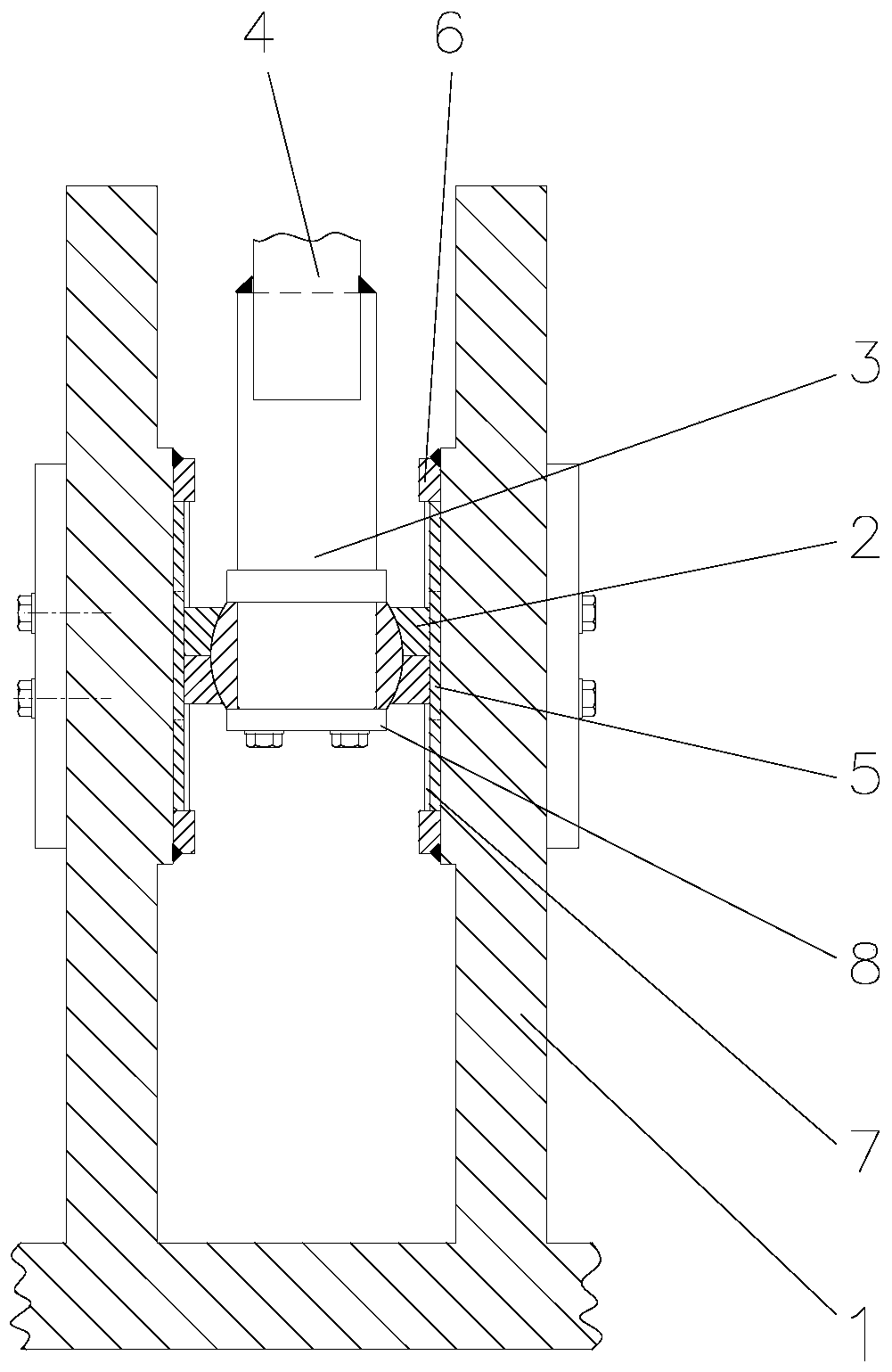

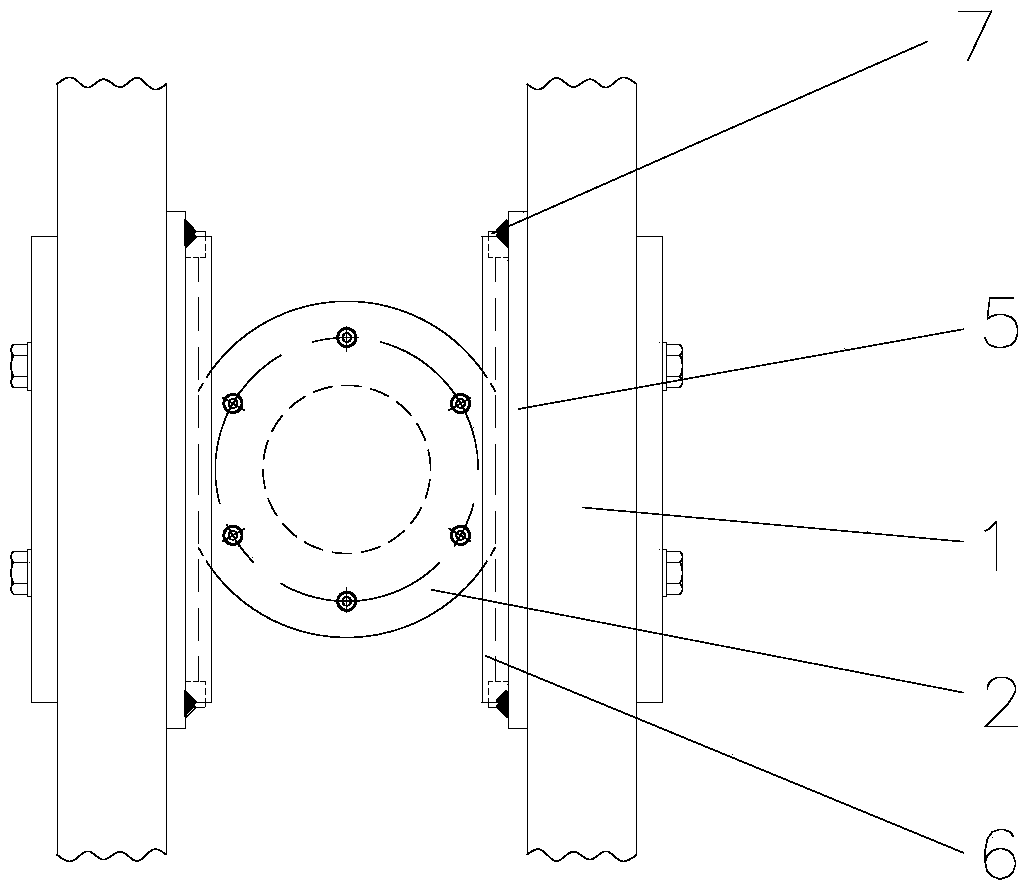

[0013] Such as figure 1 or figure 2 As shown, the present invention includes an outer ear plate 1, an articulated bearing 2, a pin shaft 3, and a middle ear plate 4; the outer ear plate 1 includes two side ears arranged at intervals, and the inner ring of the articulated bearing 2 is fixedly sleeved on one end of the pin shaft 3. The other end of the shaft 3 is fixedly connected with the middle ear plate 4; the opposite sides of the two side ears are respectively provided with inwardly protruding sliding parts, and the sliding part is fixed with a sliding plate 5, which is fixed by bolts or welding On the sliding part; the outer ring of the joint bearing 2 has two sliding planes parallel to each other, the two sliding planes of the joint bearing 2 are clamped between the two sliding plates 5, and the two sliding planes are respectively The sliding plate 5 on the same side is slidingly connected.

[0014] The sliding plate 5 is respectively provided with first limiting blocks 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com