On-site grinding device for brake pads

A brake pad and grinding technology, which is applied in the direction of grinding drive devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of inaccurate wheel matching accuracy, inaccurate matching accuracy, poor braking effect, etc. , to achieve the effect of good braking effect, fast grinding speed and high grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

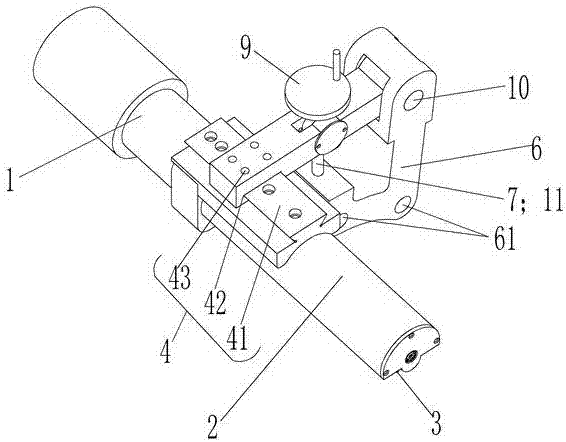

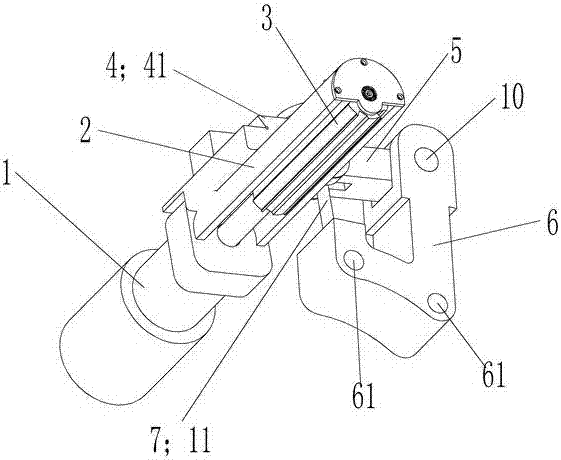

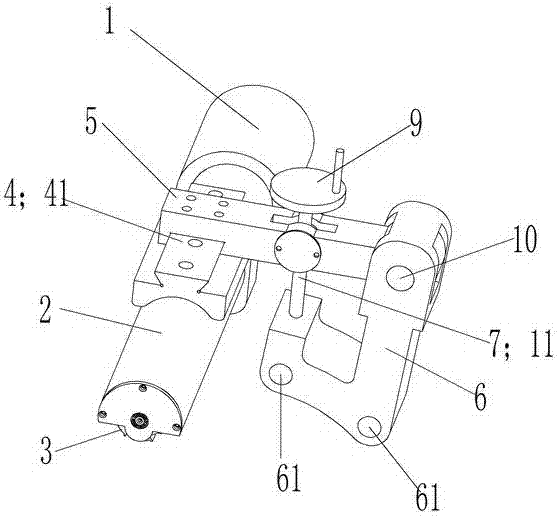

[0016] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention comprises a power input device 1, a housing 2, a grinding shaft 3, a front and rear adjustment device 4 and a grinding amount adjustment device 7. The front and rear adjustment device 4 is composed of a dovetail slider 41, a dovetail groove 42 and a tight The two ends of the grinding cutter shaft 3 are arranged in the front section of the housing 2 through bearings, and the front section of the housing 2 is in a semi-arc shape; the power input device 1 is arranged at the rear end of the housing 2, and the power input device 1 The input shaft is connected with the grinding shaft 3; the dovetail slider 41 is arranged on the housing 2, and the boom 5 has a dovetail groove 42, and the dovetail slider 41 is slid in the dovetail groove 42, and the fastening bolt 43 is connected from the dovetail groove 42. The dovetail slider 41 is fastened through the top, and the dovetail slider 41 moves ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com