A method for adjusting the output pressure of a load-sensing valve during automobile braking

A technology of output pressure and automobile braking, applied in the directions of brakes, brake components, control valves and air release valves, etc., can solve the problems of limited adjustment length and ineffectiveness, and achieve a clear algorithm process, improve calculation accuracy, and facilitate The effect of modeling and simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

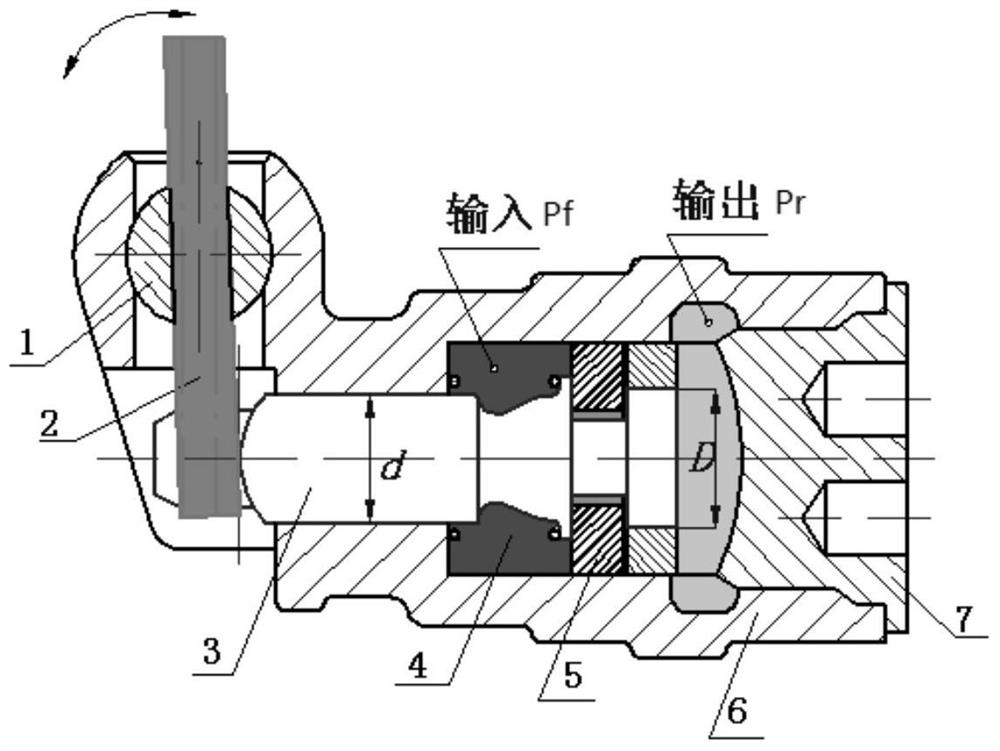

[0027] In the method for adjusting the output pressure of the load-sensing valve during the braking process of the automobile provided by this embodiment, the structure of the load-sensing valve involved is as follows: figure 1 As shown, including the valve body 6, the pin shaft 1 placed in the valve body 6, the torsion bar 2, the spool valve piston 3, the spool valve spring 4, the sealing ring 5 sleeved on the spool valve piston 3, and the valve body 6 End caps 7 on the output side.

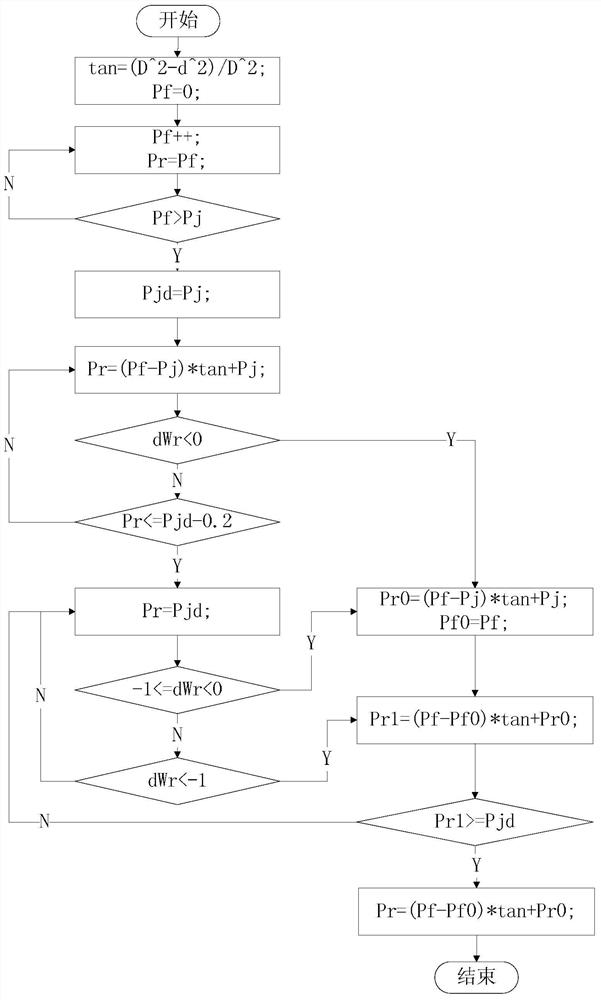

[0028] The method for testing the load-sensing valve by simulating the braking process of the automobile provided in this embodiment, the finishing process is as follows figure 2 As shown, follow the steps below:

[0029] a. Load-sensing valve self-inspection, measuring the diameters d and D of the input and output ends of the spool valve piston, calculating the slope of the static characteristic curve, and calculating the initial static characteristic ratio of the load-sensing valve according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com