Traction material bag traction device with gap detection function

A technology of traction device and detection device, which is applied in the field of machinery, can solve problems such as poor sealing of the bag body, rupture during use, and damage to items, and achieve the effect of good bag body sealing and complex mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

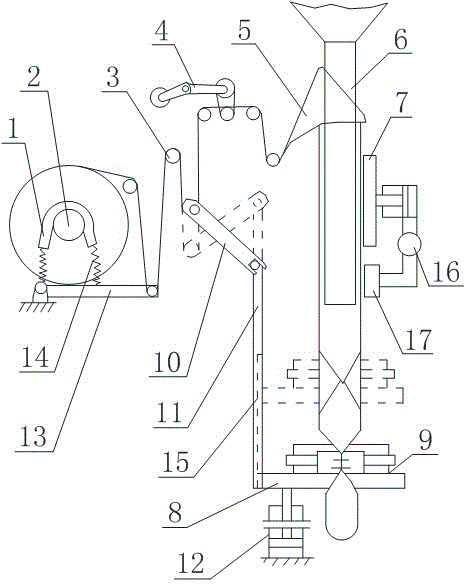

[0012] Such as figure 1 As shown, the traction bag traction device for gap detection includes a film support device 2, an adjustment plate 13 is arranged below the film support device 2, and several guide rollers 3 are arranged outside the film support device 2, one of which guides The roller 3 is connected with the adjustment plate 13; it also includes a charging conduit 6 arranged on the outside of the film supporting device 2, and a lapel forming molder 5 is arranged outside the charging conduit 6, and the lapel forming molder 5 is arranged on the guide roller 3 and the charging conduit 6 Between and close to the outer wall of the charging conduit 6, a longitudinal seam device 7 is arranged on the outer wall of the charging conduit 6, and the longitudinal seam device 7 is arranged below the lapel forming molder 5, and a slit is provided on the outer wall of the charging conduit 6 Detection device 17, the gap detection device 17 is arranged directly below the longitudinal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com