Quick molding punch

A forming punch, rapid technology, applied in the direction of forming tools, applications, household appliances, etc., can solve the problems of low production efficiency and numerous processes, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

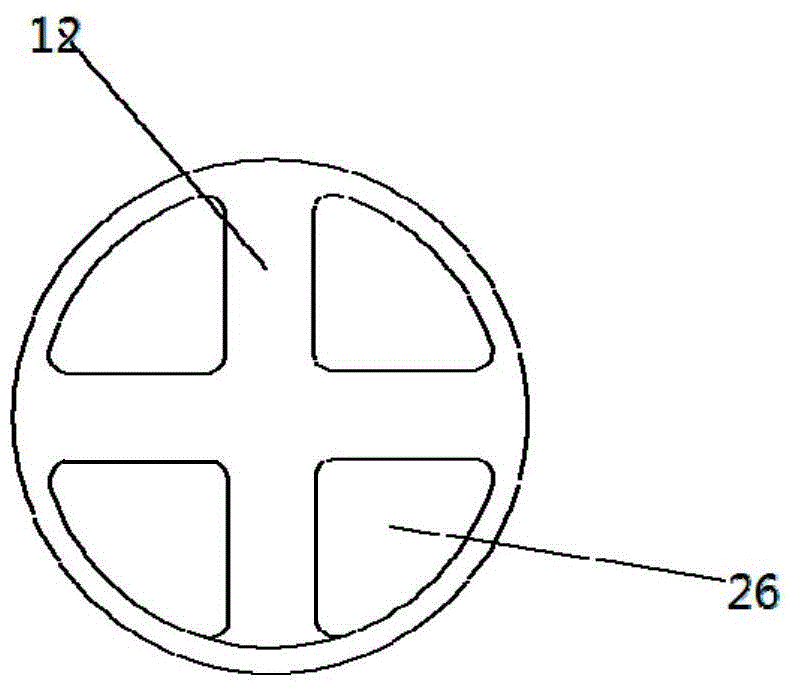

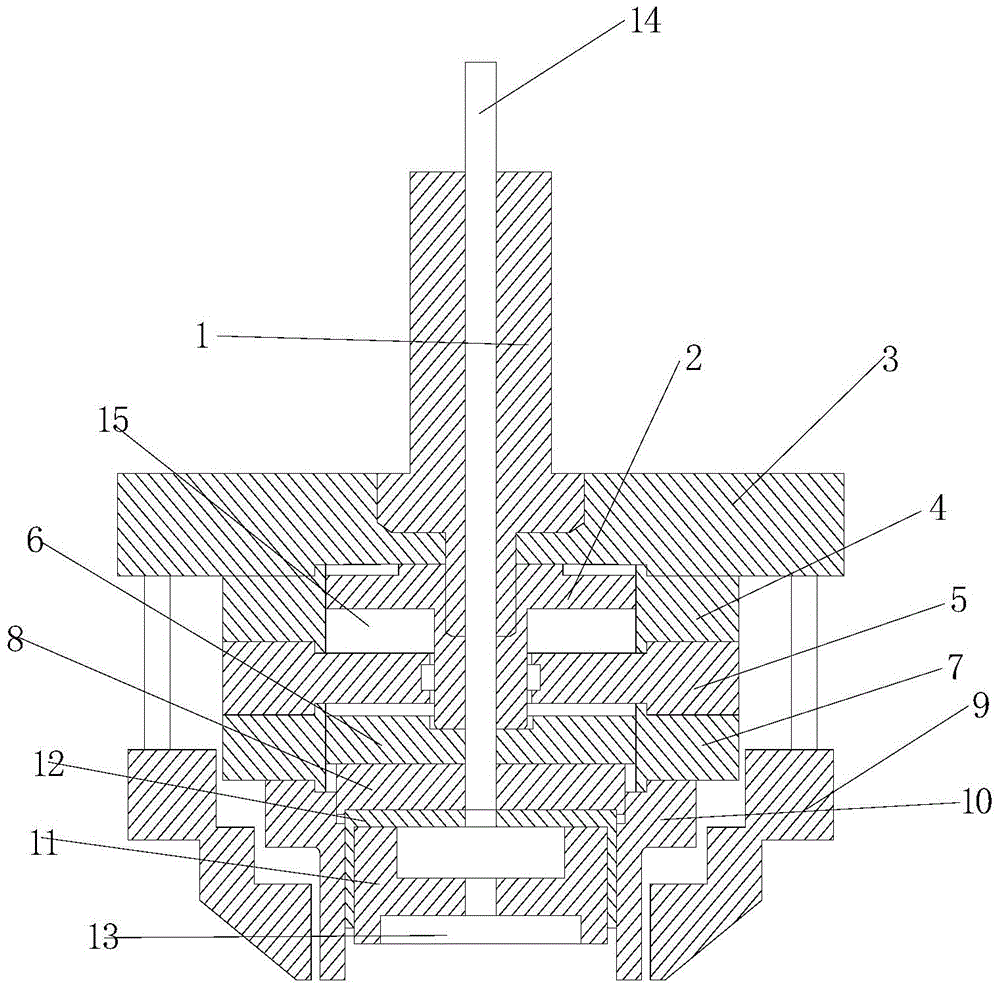

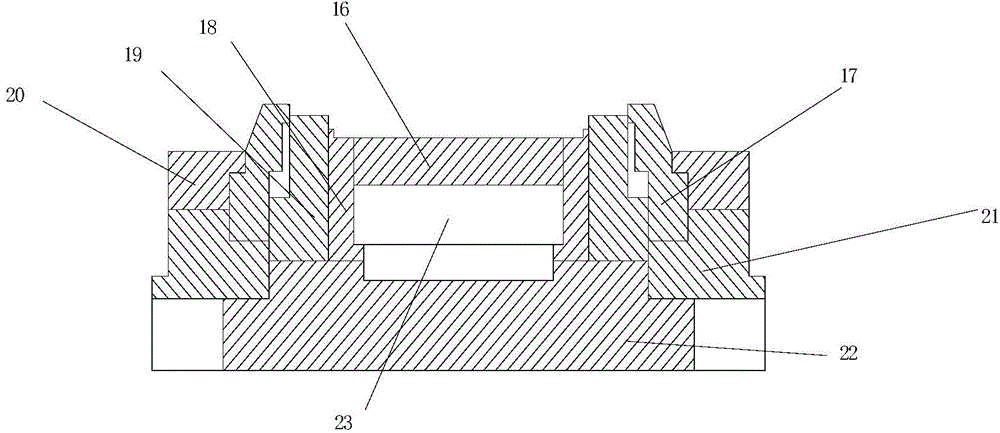

[0026] As shown in the figure, the present invention provides a rapid prototyping punch, including an upper mold unit and a lower mold unit, and the upper mold unit includes a mold handle 1, an upper mold plate 3, a first cylinder block 4, a second cylinder block 7, and a cylinder Separator body 5, first piston 2, second piston 6, fixed plate 8, punch and die 10, beating plate 12, upper mold core 11 and beating rod 14;

[0027] The mold handle 1 is fixed on the upper mold plate 3, the first cylinder block 4 is fixed on the bottom of the upper mold plate 3, the cylinder partition body 5 is fixed on the bottom of the first cylinder block 4, and the second cylinder block 7 is fixed on the cylinder partition body 5 bottom;

[0028] There is a first piston 2 in the air chamber of the first cylinder body 4, and the first piston 2 can move up and down in the air chamber of the first cylinder body 4, and there is a second piston 6 in the air chamber of the second cylinder body 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com