Spray-type air splicer

An air-twister and spray-type technology, applied in the field of air-twisters, can solve the problems of high maintenance cost, unfavorable market competition, and inability to adjust the spray volume, and achieve simple and convenient maintenance, outstanding substantive features, and stable and good appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

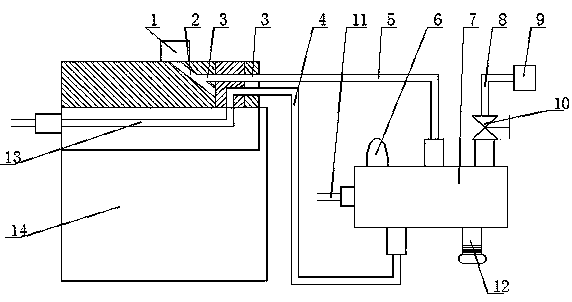

[0019] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

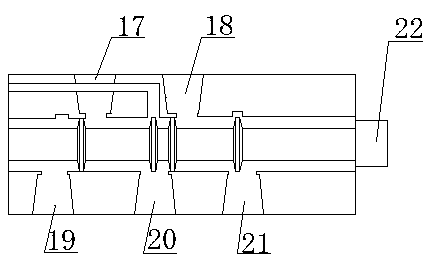

[0020] As can be seen from the accompanying drawings, a spray-type air twister includes an air twister body 14, a splicing chamber 1 is arranged in the air twister body 14, and a twisting gas passage is arranged in the air twister body 14 13. The air twister body 14 is provided with a water mist channel, the outlet of the twisting gas channel 13 communicates with the water mist generating mechanism, the outlet of the water mist generating mechanism communicates with the inlet of the water mist channel, the The outlet of the water mist channel communicates with the splicing chamber 1 .

[0021] The water mist generating mechanism includes a single air-controlled two-position five-way reversing valve 7 , and the single air-controlled two-position five-way reversing valve 7 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com