Stator winding glue spray positioning support turntable and stator winding glue spray method

A stator winding and positioning support technology, which is applied in the direction of electric components, devices for coating liquid on the surface, electromechanical devices, etc., can solve the design requirements of low operating standards, difficult control of fluorosilicone thickness accuracy, and difficulty in achieving thickness accuracy and other problems, to achieve the effect of simple and convenient installation and disassembly, high reliability of use, and improvement of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Attached below Figure 1~5 Embodiments of the present invention are described in detail.

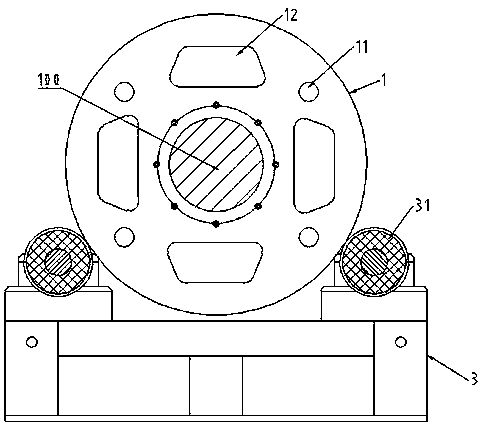

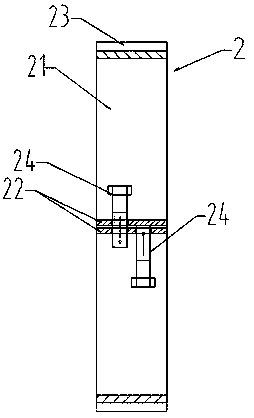

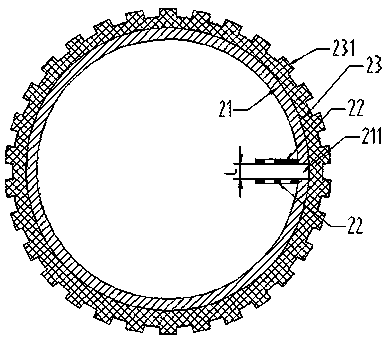

[0036] The stator winding glue spraying positioning support turntable is characterized in that it includes a support roller 1 installed at both ends of the stator winding, an expansion ring 2 and a rolling table 3 for positioning the glue spraying position, and the two expansion rings 2 are expanded tightly and attached to each other. Closed on both sides of the glue spraying position in the inner cavity of the stator winding, the outer diameter of the supporting roller 1 is larger than the outer diameter of the stator winding, the supporting roller 1 is placed on the rolling table 3, and is connected with the rotatable rotating rod 31 on the rolling table 3 Contact, the external power drives the rolling support roller 1 to rotate uniformly on the rotating rod 31, so that the stator winding rotates uniformly.

[0037] Such as figure 1 As shown, the support roller 1 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com