Concrete automatic spraying maintenance device

A concrete and sprinkler technology, applied in roads, buildings, road repairs, etc., can solve the problems of poor artificial spraying and maintenance effects, and achieve the effects of avoiding serious waste of water resources, improving quality, and increasing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

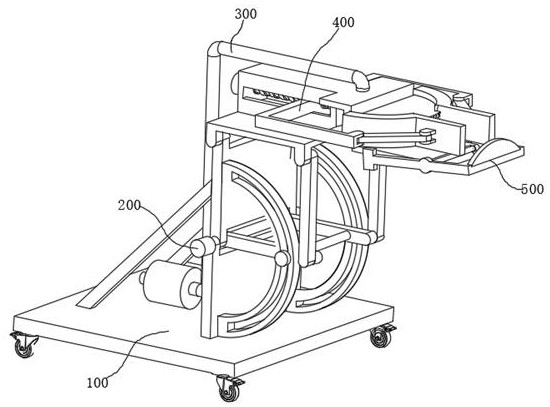

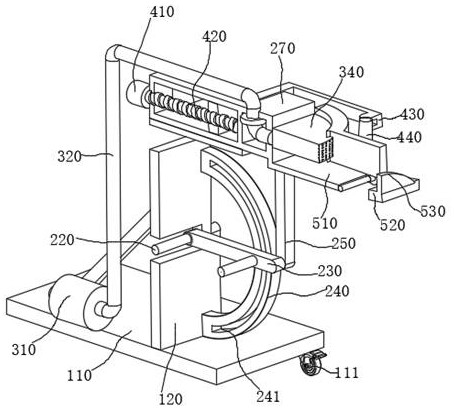

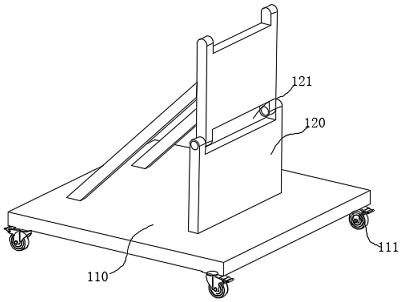

Image

Examples

Embodiment

[0045] After the concrete is poured, if the climate is hot and the air is dry, if the maintenance is not carried out in time, the water in the concrete will evaporate too quickly, forming a dehydration phenomenon, which will make the cement particles that have formed a gel body unable to fully hydrate and cannot be transformed into stable crystals. Lack of sufficient cohesion, resulting in flaking or powdering off the concrete surface. In addition, when the concrete does not have sufficient strength, the premature evaporation of water will also cause large shrinkage deformation and dry shrinkage cracks. Therefore, the maintenance of the initial stage after concrete pouring is very important.

[0046] After the surface covering or formwork is removed from the concrete, measures such as water storage, watering or covering and sprinkling should be used for moisture curing of the concrete.

[0047] Generally, the spraying maintenance of concrete is operated by manually pulling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com