Welding mask with head-up displaying automatic light adjusting filter

A head-up display and welding mask technology, which is applied in the direction of instruments, helmets, optics, etc., can solve the problems of consuming the operator's physical strength, affecting the welding work, and the operator's discomfort, so as to improve work convenience, ensure discomfort, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

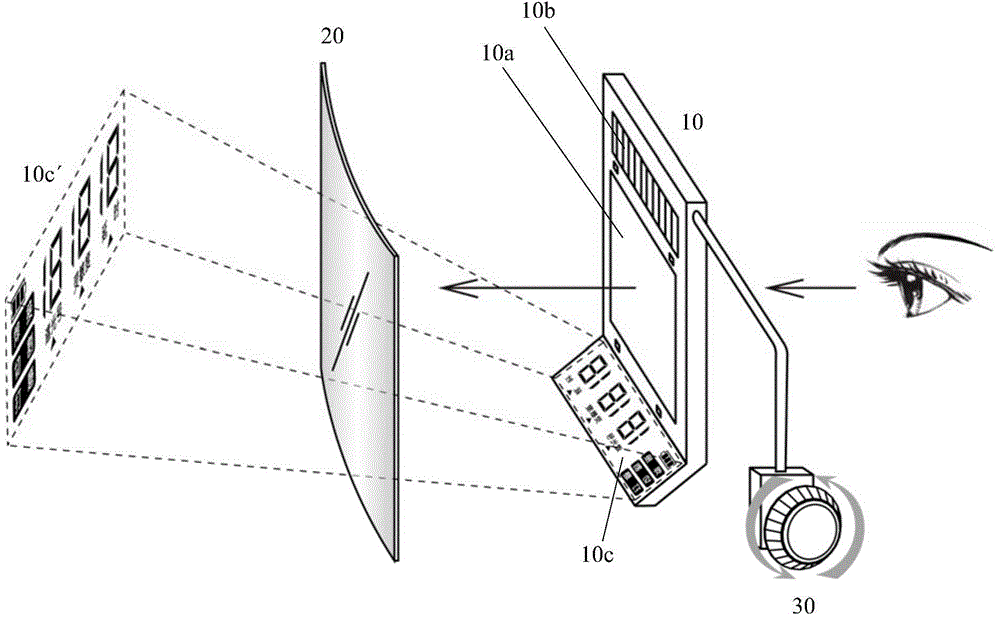

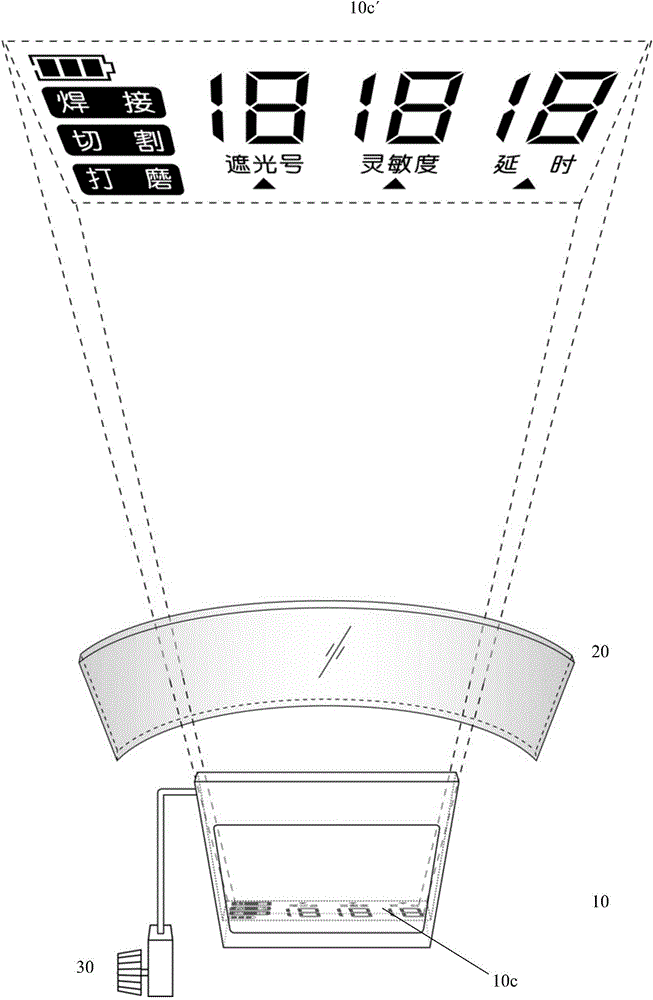

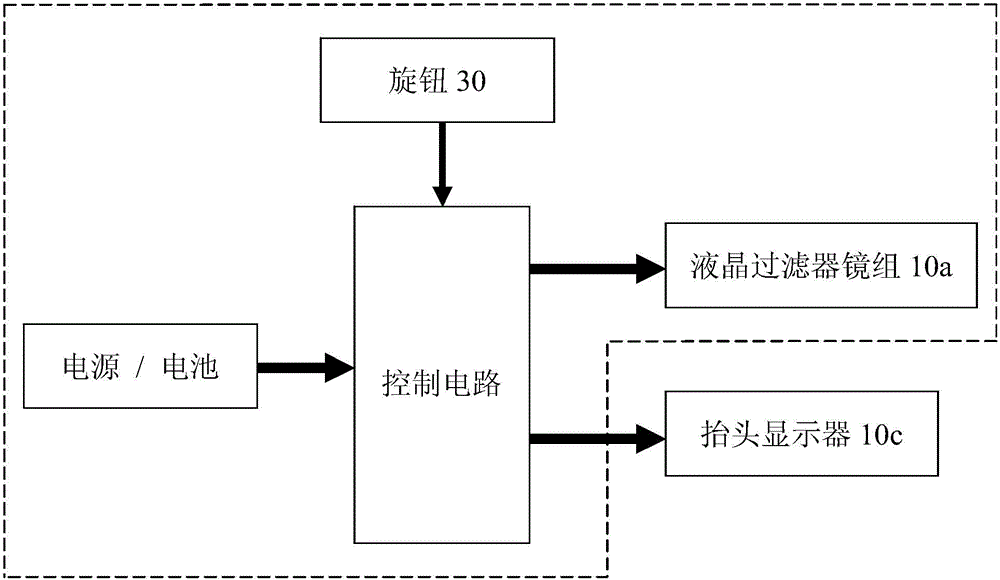

[0030] According to the Head Up Display (HUD for short) automatic dimming filter of the present invention, the operator can set various operating parameters of the automatic dimming filter without removing the mask. like figure 1 As shown, the automatic darkening filter 10 includes a liquid crystal filter lens set 10a, a solar cell set 10b, and a head-up display 10c.

[0031] A liquid crystal filter lens group 10a, a solar cell group 10b are located on the main body of the automatic darkening filter 10, and a head-up display 10c is obliquely disposed under the main body. The head-up display 10c is a liquid crystal display, on which all operating parameters related to the auto-dimming filter 10 can be displayed in good time.

[0032] It should be pointed out that, except for the head-up display 10c and the content described ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap