Production line and production technology for manufacturing foam ceramic insulation board

A technology of foam ceramics and insulation boards, which is applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of difficult guarantee of product mechanical strength and low processing efficiency, and achieve mechanical strength improvement, high production efficiency, and uniform cloth distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those of ordinary skill in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

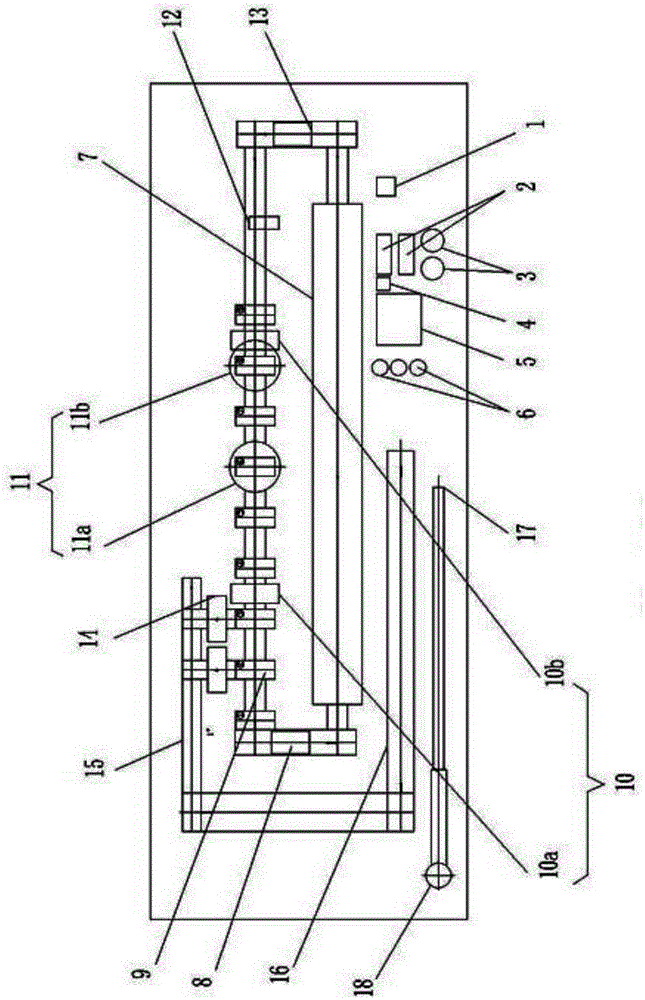

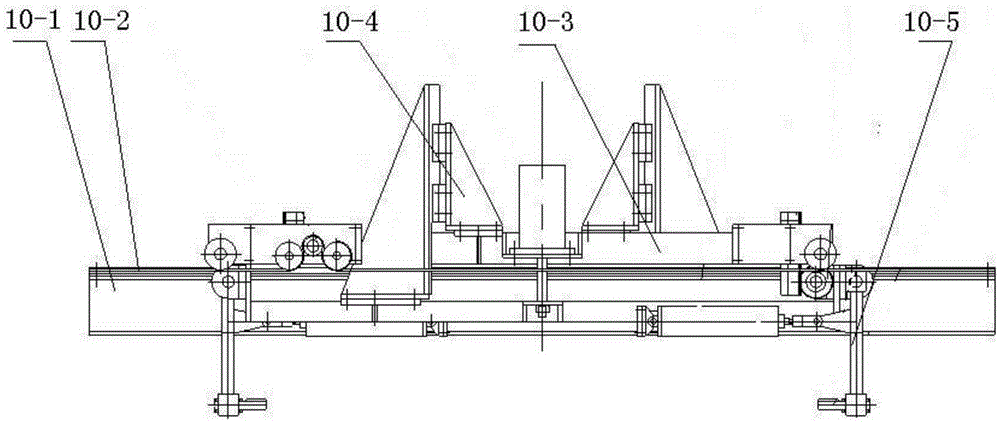

[0029] Such as figure 1 , figure 2 As shown, a production line for manufacturing foam ceramic insulation boards includes: crusher 1, ball mill 2, slurry tank 3, plunger pump 4, spray drying tower 5, silo 6, kiln 7, kiln outlet machine 8, Kiln car 9, mold automatic loading and unloading vehicle 10, automatic distributing machine 11, stepping machine 12, kiln entering machine 13, automatic unloading car 14, conveying line 15, automatic cutting line 16, waste conveyor 17 and waste bin 18.

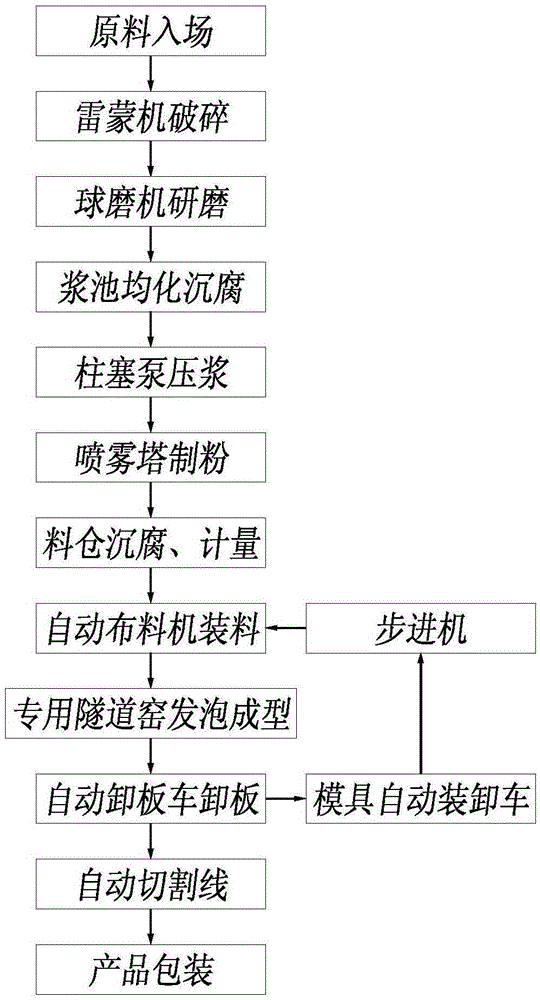

[0030] The crusher 1 crushes various raw materials into small pieces, mixes them in proportion and puts them into the ball mill 2 to run for a period of time to make mud and put them into the slurry pool 3 . The mud in the slur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap