A closed-cell foaming process of sebs/eva blend material

A process method and closed-cell technology, which is applied in the field of closed-cell foaming of SEBS/EVA blended materials, can solve the problems of product color difference, poor plasticization, black spots, etc., and achieves easy operation, low product processing cost, and process steps. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

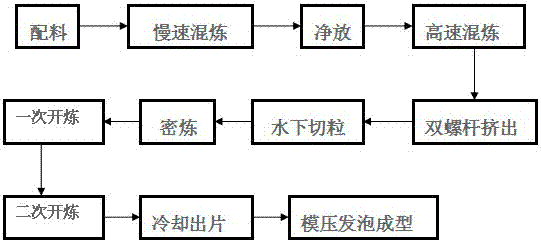

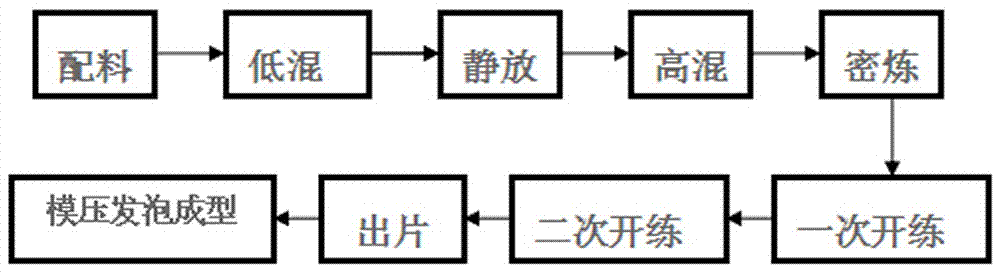

[0060] A kind of SEBS / EVA blended material closed-cell foaming process of the present invention comprises the following steps:

[0061] ①Batching and low speed mixing

[0062] Take 26 parts by weight of SEBS and 50 parts by weight of white mineral oil and mix them in a low-speed mixer, control the speed at 1455 rpm, mix at a temperature of 40°C, and take 12 minutes to fully mix and absorb SEBS powder and white mineral oil;

[0063] ②Stay

[0064] Place the above-mentioned mixture in the trough and let it stand for 48 hours, so that the SEBS powder can further absorb white mineral oil;

[0065] ③High-speed mixing

[0066] Put the SEBS powder that has fully absorbed white mineral oil in a high-speed mixer, control the speed at 2850 rpm, mix at a temperature of 65°C, and mix for 8 minutes; the SEBS high-mixture is obtained;

[0067] ④ Banbury

[0068] Get above-mentioned SEBS high compound 40 weight parts, Vinyl acetate 5 parts by weight of EVA with a content of 18%, Vinyl ac...

Embodiment 2

[0082] A kind of SEBS / EVA blended material closed-cell foaming process of the present invention comprises the following steps:

[0083] ①Batching and low speed mixing

[0084] Take 23 parts by weight of SEBS and 40 parts by weight of white mineral oil and mix them in a low-speed mixer, control the speed at 1450 rpm, mix at a temperature of 30°C, and mix them for 10 minutes to fully mix SEBS powder and white mineral oil;

[0085] ②Stay

[0086] Place the above-mentioned mixture in the trough and let it stand for 24 hours, so that the SEBS powder can further absorb the white mineral oil;

[0087] ③High-speed mixing

[0088] Put the SEBS powder that has fully absorbed white mineral oil in a high-speed mixer, control the rotation speed at 2600 rpm, mix at a temperature of 60°C, and mix for 8 minutes; the SEBS high-mixture is obtained;

[0089] ④ Banbury

[0090] Get 10 parts by weight of the above-mentioned SEBS high compound, 10 parts by weight of EVA, CaCO 3 50 parts by wei...

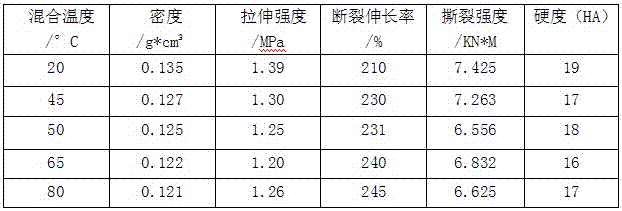

Embodiment 3

[0093] A kind of SEBS / EVA blended material closed-cell foaming process of the present invention comprises the following steps:

[0094] ①Batching and low speed mixing

[0095] Take 28 parts by weight of SEBS and 60 parts by weight of white mineral oil and mix them in a low-speed mixer, control the rotation speed at 1470 rpm, mix at a temperature of 40°C, and take 15 minutes to fully mix SEBS powder and white mineral oil;

[0096] ②Stay

[0097] Above-mentioned mixed material is placed in feed tank and left standstill for 50 hours, SEBS powder is further absorbed white mineral oil;

[0098] ③High-speed mixing

[0099] Put the SEBS powder that has fully absorbed white mineral oil in a high-speed mixer, control the speed at 2900 rpm, mix at a temperature of 70°C, and mix for 10 minutes; the SEBS high-mixture is obtained;

[0100] ④ Banbury

[0101] Get 40 parts by weight of the above-mentioned SEBS high compound, 40 parts by weight of EVA, CaCO 3 50 parts by weight, 25 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com