Single-pneumatic disc fixing device

A technology of fixing devices and discs, which is applied in the field of tooling and fixtures, can solve the problems of low production efficiency, low pass rate of workpiece products, difficulty in clamping and positioning, and reduced production efficiency, so as to improve quality and work efficiency, and accurately punch holes , the effect of quick pick and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

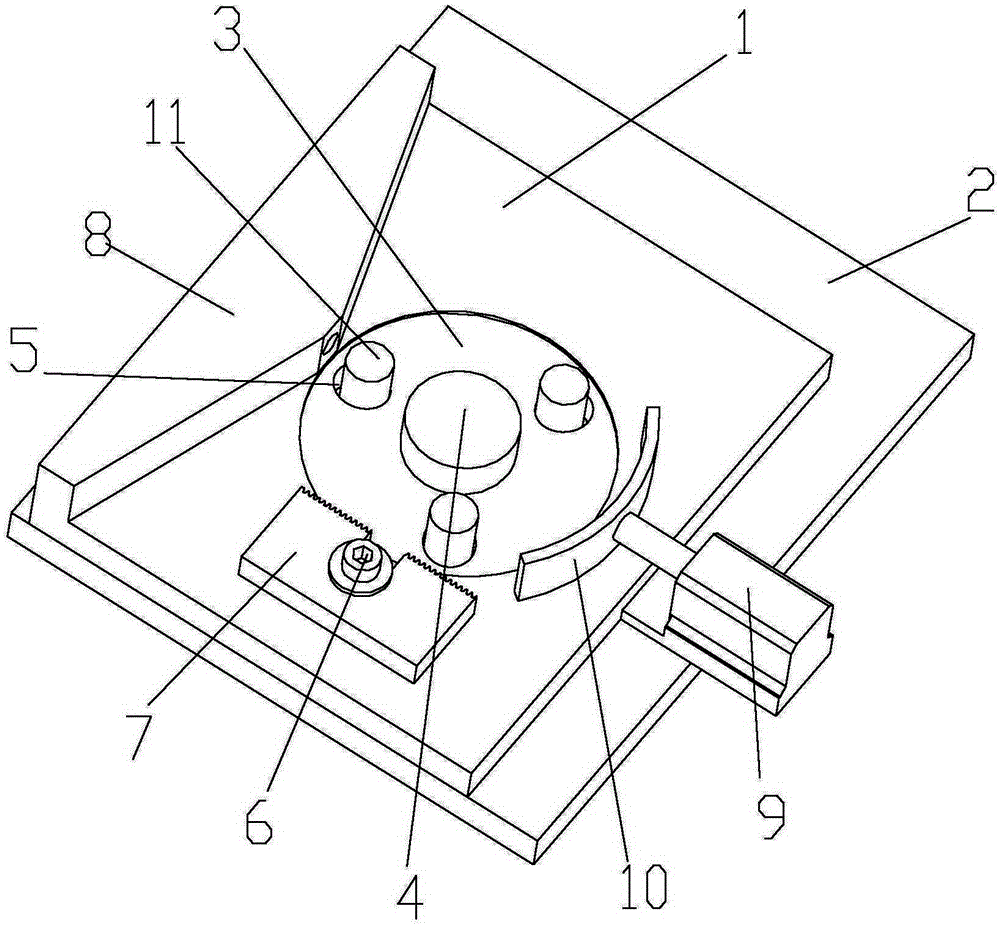

[0013] as attached figure 1 Shown is a single pneumatic disc fixing device according to the present invention, which includes a base 1 and a push rod seat 2; a disc groove 3 is provided on the base 1; Column 4; ejector pin holes 5 are uniformly distributed in the disc groove 3, and there are three ejector pin holes 5 distributed at 120° in the disc groove 3; one side of the disc groove 3 is provided with a The bolt 6 is connected with the clamping block 7 with the bolt 6 as the center of rotation, and the end face of the clamping block 7 towards the side of the disc groove 3 is provided with locking teeth; one end of the base 1 is provided with a baffle plate 8; the periphery of the disc groove 3 There is also an arc-shaped plate 10 controlled by the clamping cylinder 9; the ejector rod seat 2 is provided with a ejector rod 11 matched with the ejector rod hole 5 on the disk groove 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com