Drilling device for automatic feeding

A technology of drilling equipment and automatic feeding, which is used in drilling/drilling equipment, boring/drilling, metal processing equipment, etc. To improve the accuracy of punching, eliminate positioning errors, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

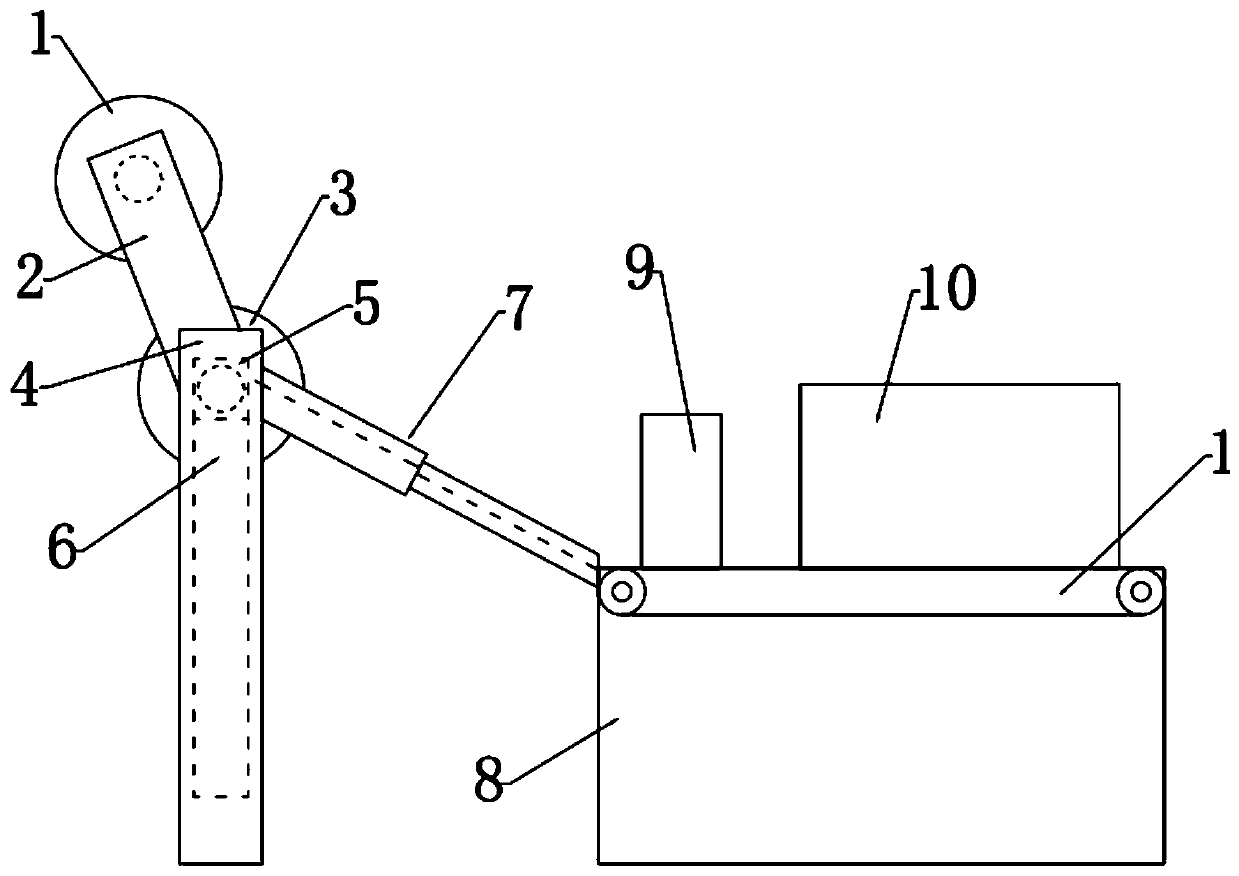

[0031] see Figure 1~4 , in the embodiment of the present invention, an automatic feeding drilling equipment includes a base 8, a feeding mechanism is provided on the left side of the base 8, and the feeding mechanism and the base 8 are connected by a conveying mechanism 7, so The top of the base 8 is fixedly connected with a fixing mechanism 9, the right side of the fixing mechanism 9 is provided with a protective shell 10 fixedly connected with the base 8, the inside of the protective shell 10 is provided with a punching mechanism, and the lower side of the punching mechanism A conveyor belt 11 is provided.

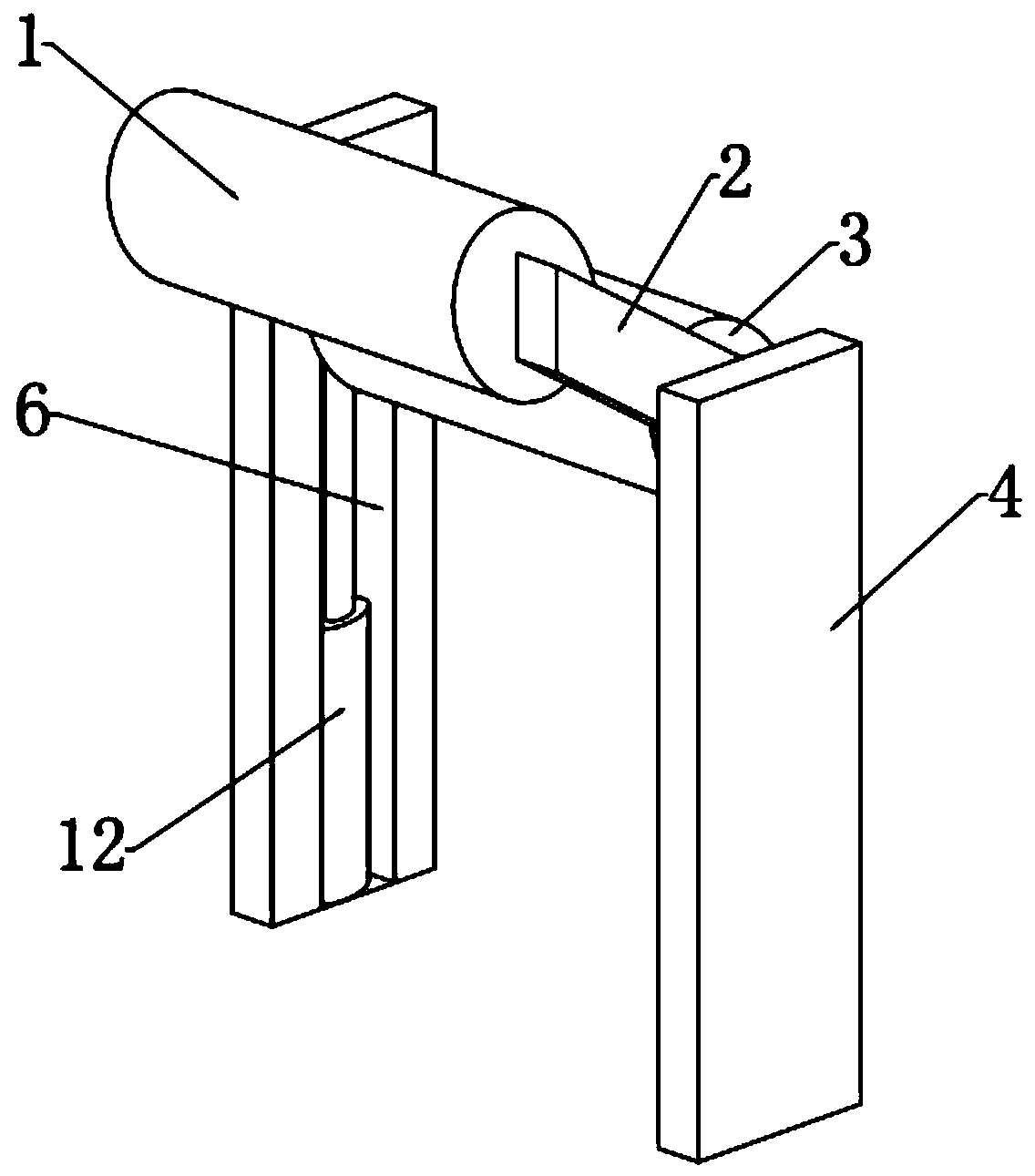

[0032] In this embodiment, the feeding mechanism includes a first conveying roller 1, a connecting rod 2, a second conveying roller 3, a support column 4, a slider 5, a slide rail 6 and a first telescopic rod 12, and the support column 4 It is arranged on the left side of the base 8, and the second transmission roller 3 is arranged between the support columns 4 on the ...

Embodiment 2

[0041] A drilling mechanical equipment, comprising the automatic feeding drilling equipment described in Embodiment 1.

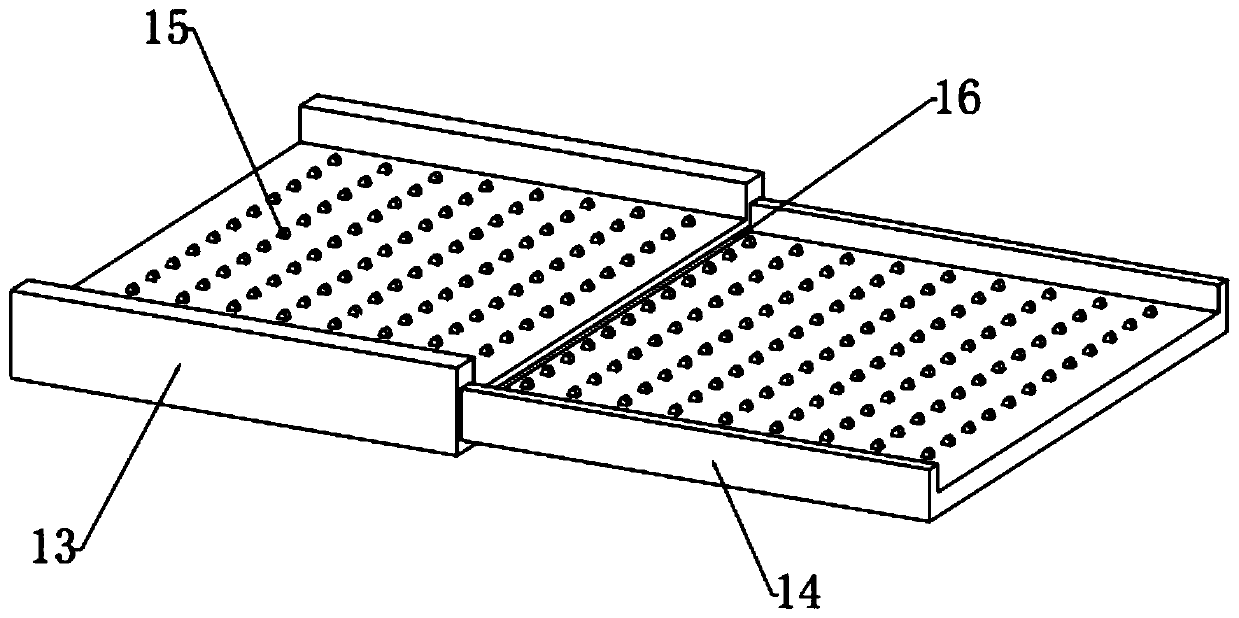

[0042] The automatic feeding drilling equipment can make the first conveying roller 1 contact with the raw material and drive the material to move to the right, and pass through the second conveying roller 3. Make the material fall into the conveying mechanism 7, realize the automatic feeding of raw materials, reduce the labor consumption, and improve the production efficiency. By setting the conveying mechanism 7, the material can be avoided to move back and forth, thereby eliminating the positioning error and improving the drilling efficiency. Accuracy, by adopting the conveying wheel 15 of rubber material, it can play the role of shock absorption and buffering, and at the same time, it can protect the surface of the raw material. By setting the fixing device, the raw material can be fixed horizontally, avoiding the side slip of the raw material Set fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com