Transmission gear

A technology of transmission gears and ring gears, which is used in transmissions, transmission parts, gear transmissions, etc., can solve the problems that the output components cannot be accurately positioned, cannot be correctly controlled and combined with the output components, etc., and achieves long service life and simple transformation. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment

[0016] The present invention is described further:

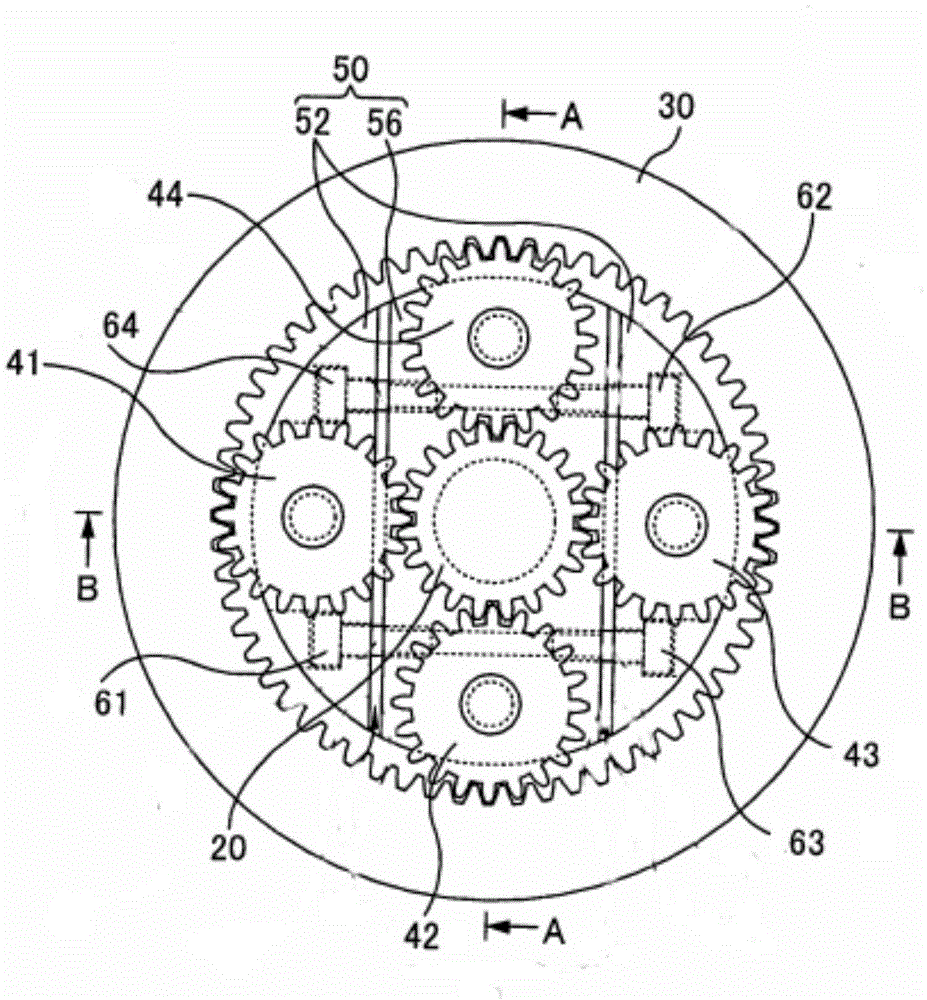

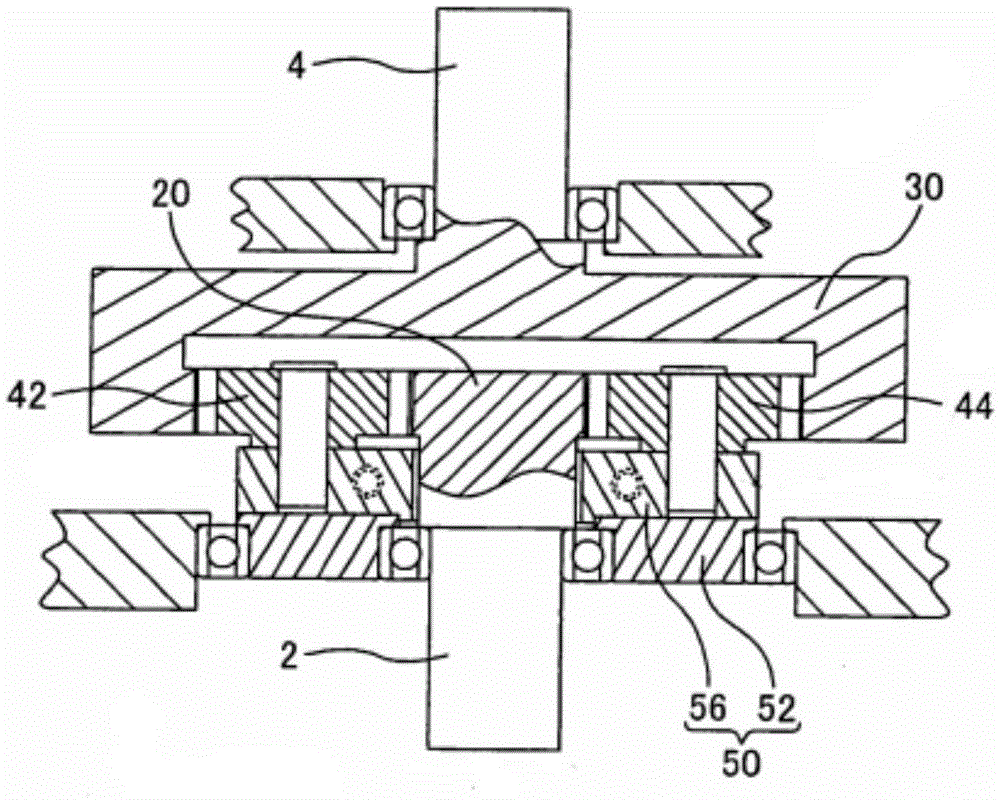

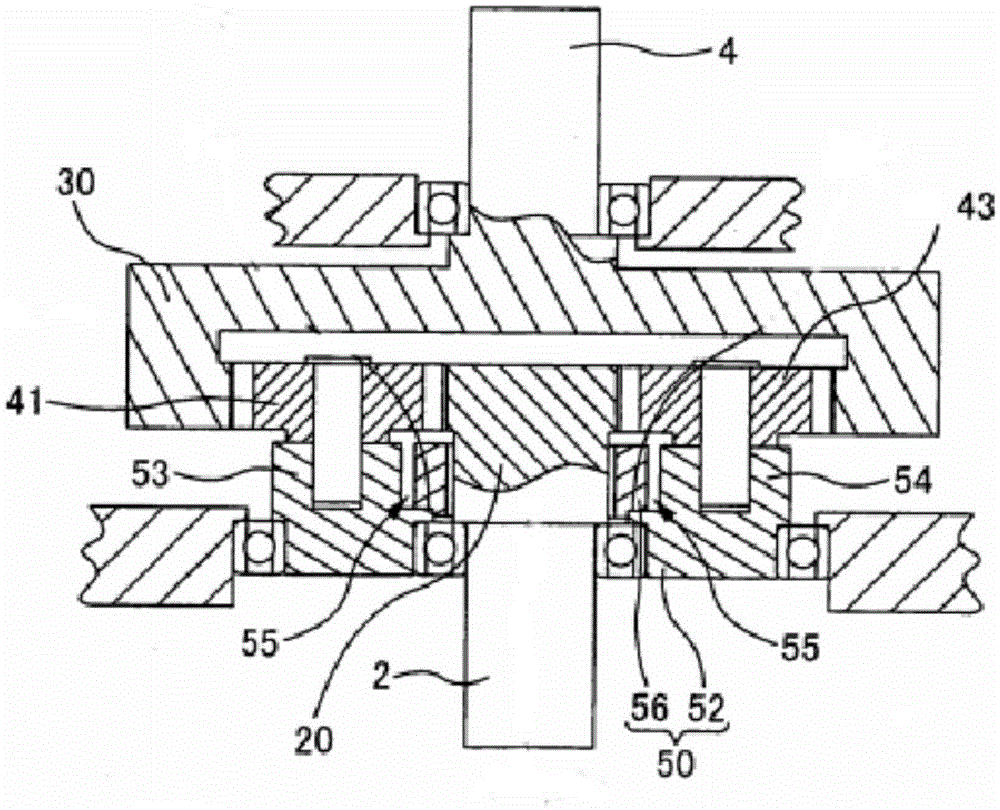

[0017] like Figure 1-Figure 3 As shown, a transmission gear includes a sun gear 20, a ring gear 30 and a frame body 50, the sun gear 20 is sleeved on the input shaft 2, the ring gear 30 is sleeved on the output shaft 4, and the sun gear 20 A first planetary gear 41, a second planetary gear 42, a third planetary gear 43 and a fourth planetary gear 44 are arranged between the ring gear 30;

[0018] The first planetary gear 41 , the second planetary gear 42 , the third planetary gear 43 and the fourth planetary gear 44 mesh with the sun gear 20 and the ring gear 30 simultaneously;

[0019] The frame 50 includes a first frame 52 and a second frame 56, the first frame 52 includes a first planetary gear support portion 53, and the second frame 56 includes a second planetary gear support portion 54;

[0020] The first planetary gear 41 and the third planetar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com