Auto-levelling device of carding machine

An autoleveling and carding technology, which is applied to deburring devices, spinning machines, spinning machines with continuous winding, etc., can solve the problems of complicated machinery and high renovation costs, and achieves improved quality, simple renovation, Highly generalizable and adaptive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

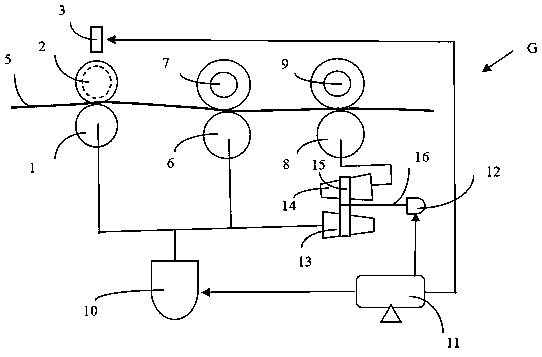

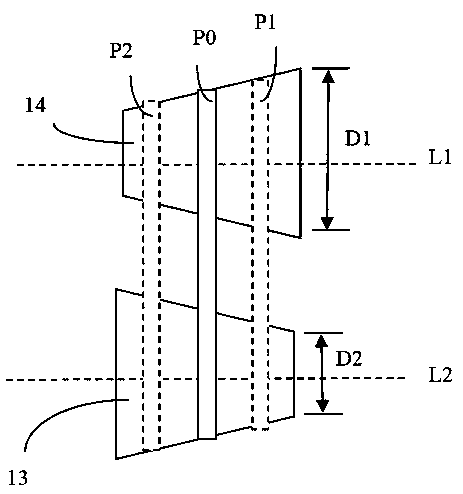

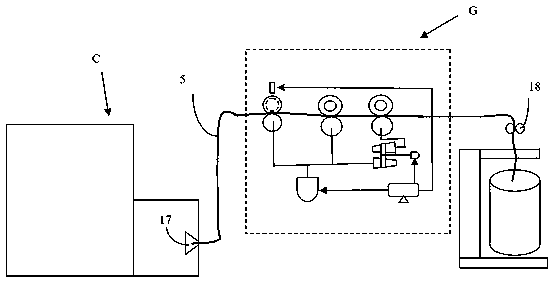

[0055] figure 1 It is a schematic diagram of an embodiment of an autoleveling device for a carding machine in the present invention. The carding machine autoleveling device G consists of a pair of rollers consisting of a pair of convex rollers 2 and concave rollers 1, a pair of rollers consisting of a pair of front bottom rollers 6 and front top roller top rollers 7, a pair of rear bottom rollers Roller pairs consisting of 8 and rear top roller top rollers 9. Wherein, the frequency conversion motor 10 is connected with the front bottom roller 6 to drive the bottom front bottom roller 6 to rotate. The frequency conversion motor 10 is connected with the lower cone wheel 13 to drive the lower cone wheel 13 to rotate. The lower cone wheel 13 and the upper cone wheel 14 are connected by a belt 15, and the lower cone wheel 13 drives the upper cone wheel 14 to rotate through the belt 15. The upper conical wheel 14 is connected with the back bottom roller 8 to drive the bottom roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com