Adjusting method for division error of angle measuring equipment

A kind of angle measurement equipment and indexing error technology, which is applied in angle/taper measurement and other directions, can solve the problems that the adjustment effect is difficult to meet the precise requirements, the efficiency is low, the size and direction of the eccentricity cannot be accurately determined, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The invention provides a method for adjusting and repairing the indexing error of angle measuring equipment, which is characterized in that: the method for adjusting and repairing the indexing error of angle measuring equipment:

[0080] 1) The influence of eccentricity on the indexing error of angle measuring equipment

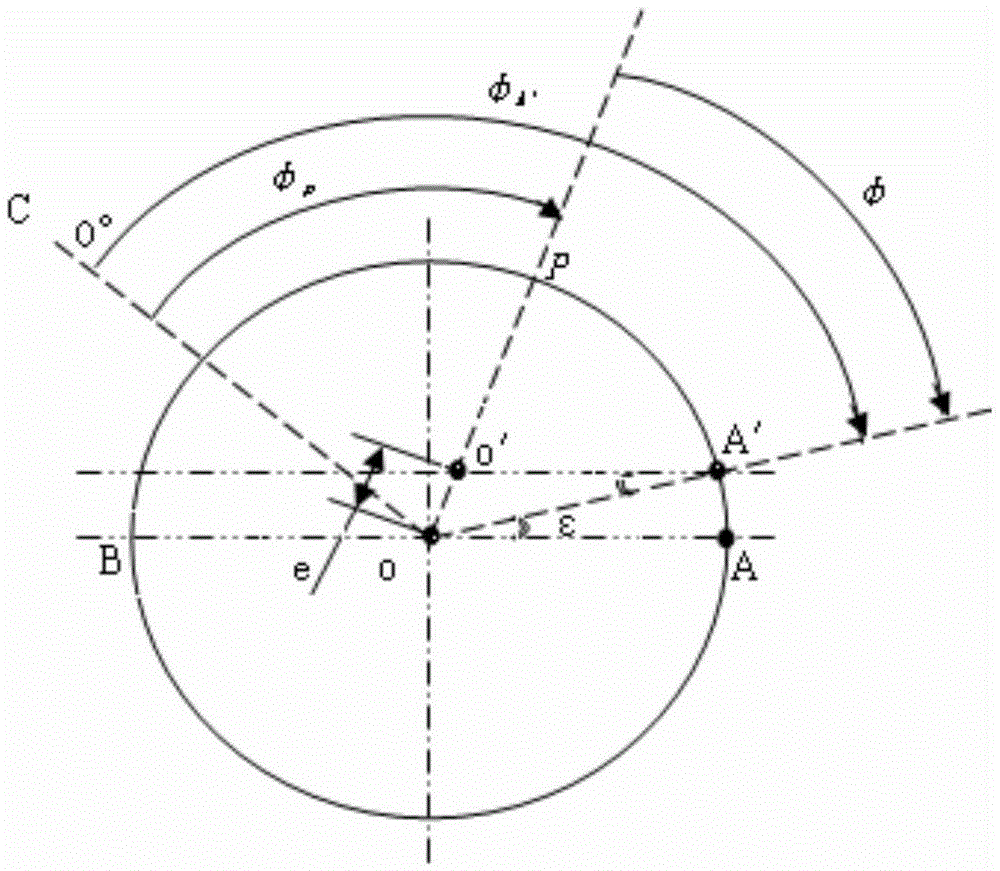

[0081] When the dial used as the angle measurement standard is installed on the main shaft of the angle measurement equipment, it often happens that the circle center of the scale line does not coincide with the rotation center of the instrument shaft system, such as figure 1 . If the center of the graduation line of the dial is O, the center of rotation of the shaft system of the instrument is O', the length of the eccentricity is represented by e, the direction of the eccentricity is at the position of the graduation line p, and the angle value of the p graduation line to the 0° graduation line is φ p .

[0082] When O and O' do not coincide and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com