A telescopic belt conveyor

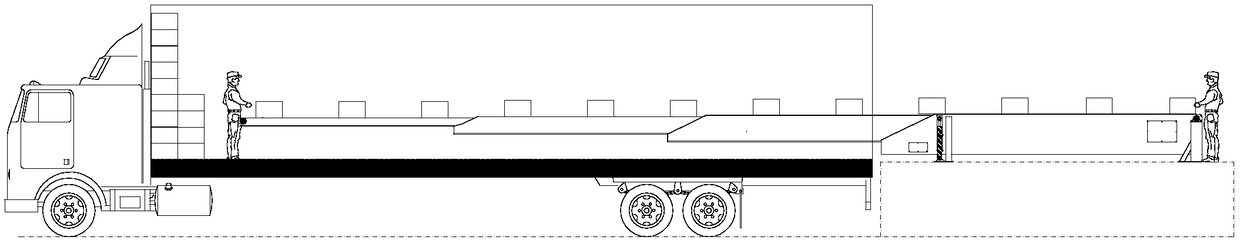

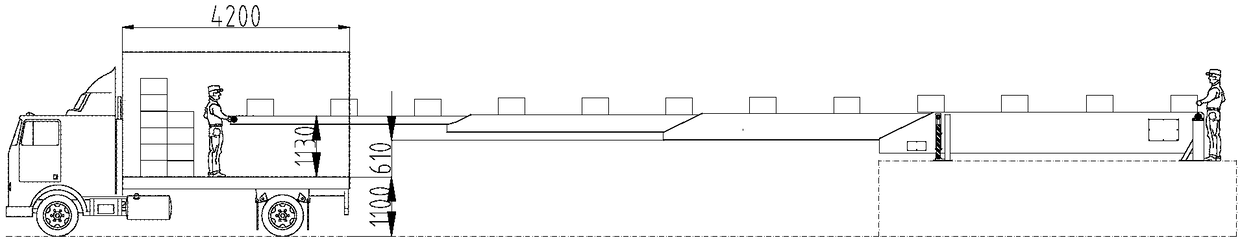

A telescopic belt conveyor and telescopic machine technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of cumbersome use, waste of resources, and large use limitations, and achieve the effects of avoiding accidental injury, stable rotation and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

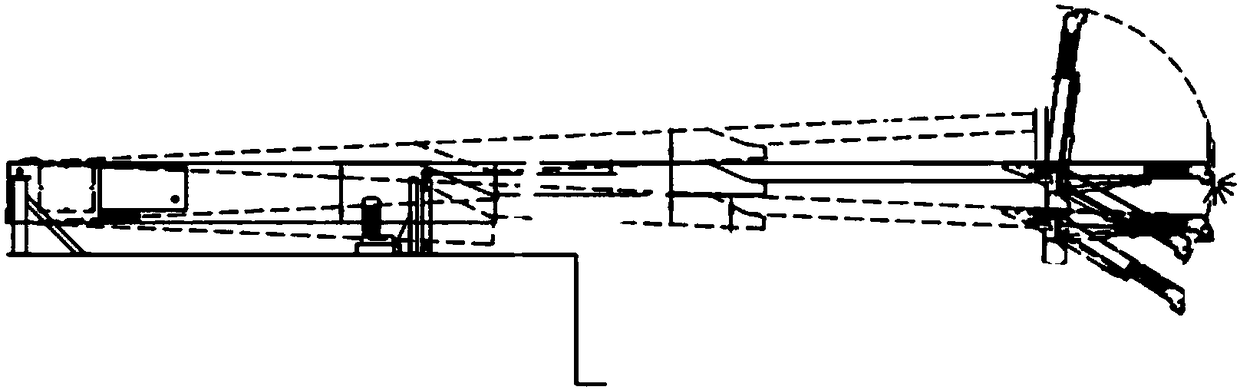

[0025] Embodiment 1: A telescopic belt conveyor includes a telescopic frame and a driving device. The telescopic frame is composed of several telescopic sections nested. A telescopic section is the front telescopic section, and the front telescopic section is composed of two telescopic sections, such as Figure 4 As shown, one end of the first telescopic section 1 is connected to the second telescopic section 2 through a rotating support mechanism, and the other end is nested in the next telescopic section. The rotating support mechanism includes a connecting piece 3 and a supporting piece:

[0026] The connecting piece 3 is composed of a first connecting piece 31 and a second connecting piece 32, the second connecting piece 32 is fixed on the second expansion joint 2, and the first connecting piece 31 is fixed on the first expansion joint 1, as Figure 5 , 6 As shown, both the first connector 31 and the second connector 32 are composed of a front end and a rear end, the fro...

Embodiment 2

[0030] Embodiment 2: The only difference between this embodiment and Embodiment 1 is that the rotating support mechanism is a rotating gear set, one end of the first expansion joint is connected with the second expansion joint through the rotating gear set, and the second expansion joint is connected to the rotating gear set. Driven by the drive, it rotates longitudinally around the first expansion joint and remains in the rotating position. When the telescopic machine needs to be retracted, the rotating gear set drives the second telescopic joint to rotate to its original position, that is, it is located on the same level as the first telescopic joint, and the first telescopic joint and the second telescopic joint are retracted to the original position driven by the driving device. in the next telescopic segment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com