Belt arrangement structure of a petroleum coke water tank at the bottom of the tank

A configuration structure and petroleum coke technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as increased energy consumption in calcination workshops, reduced economic benefits of enterprises, and reduced dehydration effects of drain bins, etc., to achieve drainage system design Simple and easy, optimized dehydration effect, good draining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

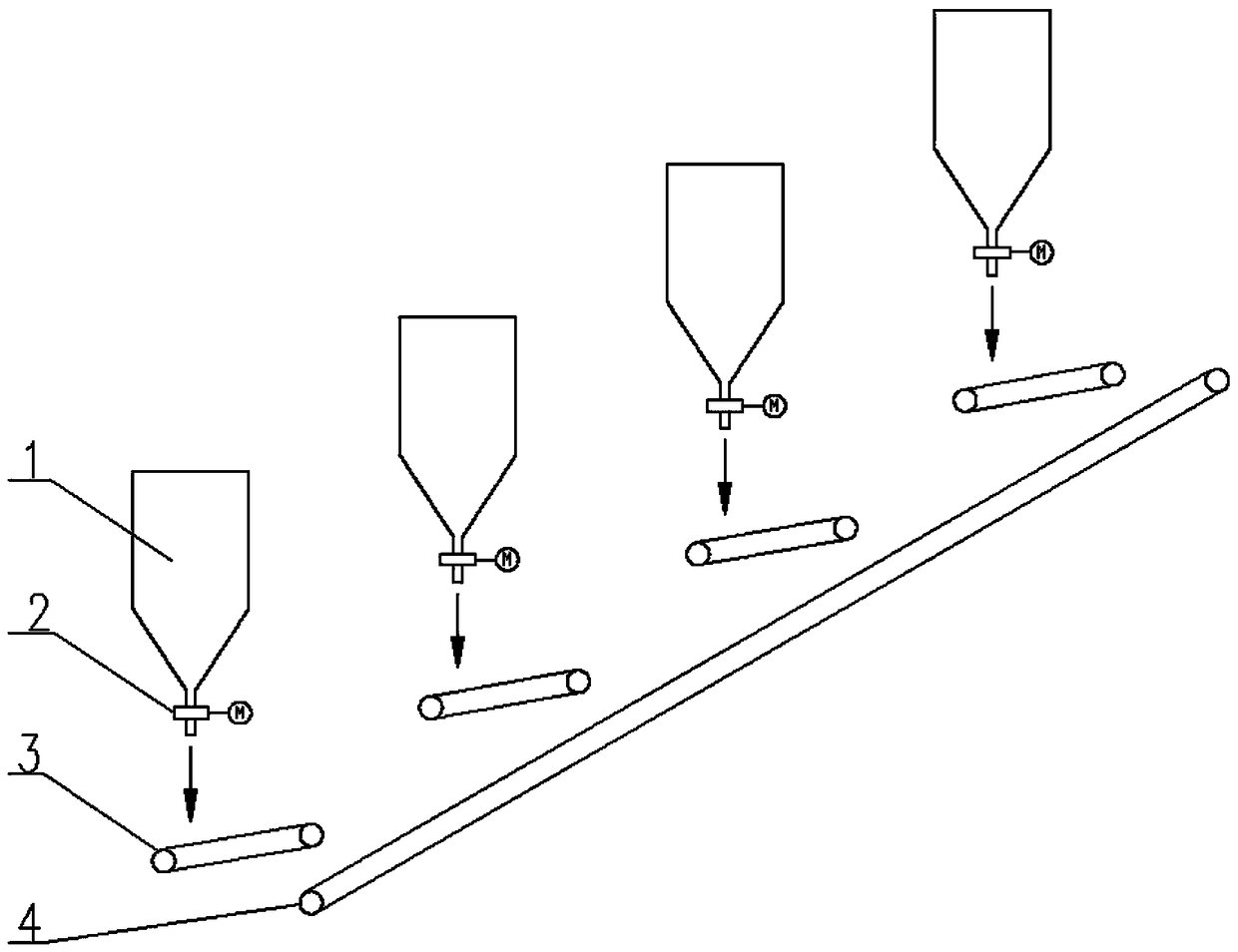

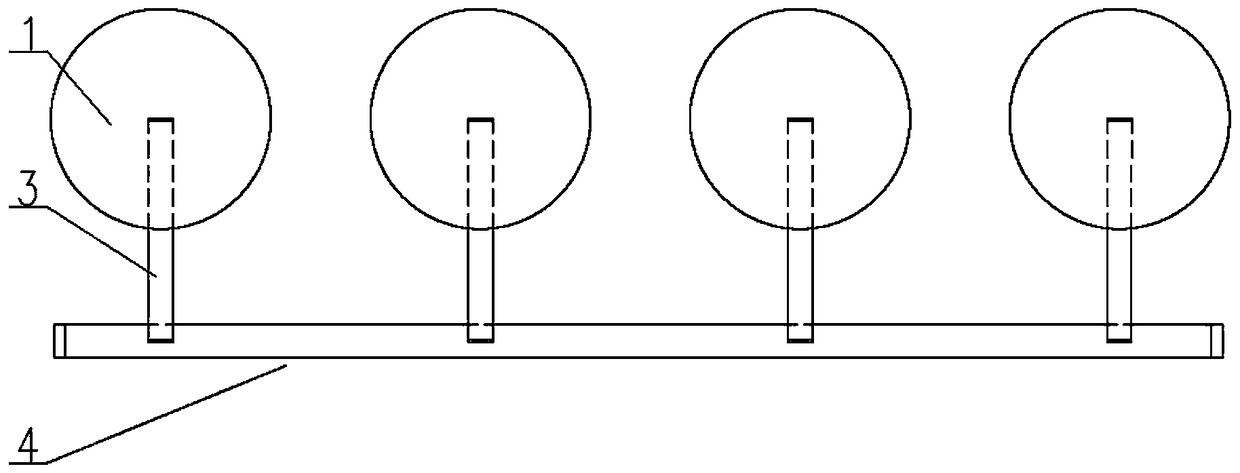

[0015] As shown in the figure, a belt configuration structure at the bottom of a petroleum coke drain bin of the present invention, a transfer belt 3 is placed under each drain bin 1, the discharge end of the transfer belt 3 is higher than the feed end, and the transfer belt 3 The material on the feeder is sent to the main conveying belt 4 through the discharge end, and finally the material is conveyed to the subsequent section. The inclination angle of the transfer belt is 15 degrees. The water discharged from the drain bin directly drops to the drain along the transfer belt from the bottom of the belt under the action of gravity. The outlet of the drain bin 1 is provided with a feed valve 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com