A multi-element synergistic plug-removing agent

A technology of synergistic effect and plug-removing agent, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of narrow application range, low success rate of plug-removal, unsatisfactory plug-removal effect, etc., reaching the scope of application Wide, high success rate of plugging removal, improve the effect of plugging removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a multivariate synergistic block-removing agent, and its component mass ratio is composed of: 80-120 parts of water (tap water), 5-10 parts of cleaning and dissolving agent, 15-20 parts of corrosion agent, ammonium bifluoride 0.5-1 part, 0.4-0.6 part of Ninar, 2.5-3 parts of dodecyltrimethylammonium chloride, 0.1-0.3 part of ammonium persulfate, 2.5-3 parts of SA-3 corrosion inhibitor, HY215 for acidification 3-5 parts of iron ion stabilizer.

[0039] For example, the multi-element synergistic plug-removing agent has the following composition mass ratio: 120 parts of tap water; 5 parts of cleaning solvent; 15 parts of corrosion agent; 0.5 parts of ammonium bifluoride; 0.4 parts of Ninar; 2.5 parts of alkyltrimethylammonium chloride; 0.1 part of ammonium persulfate; 2.5 parts of SA-3 corrosion inhibitor; 3 parts of iron ion stabilizer for HY215 acidification. When in use, the multi-component synergistic plug-removing agent is transported to the ...

Embodiment 2

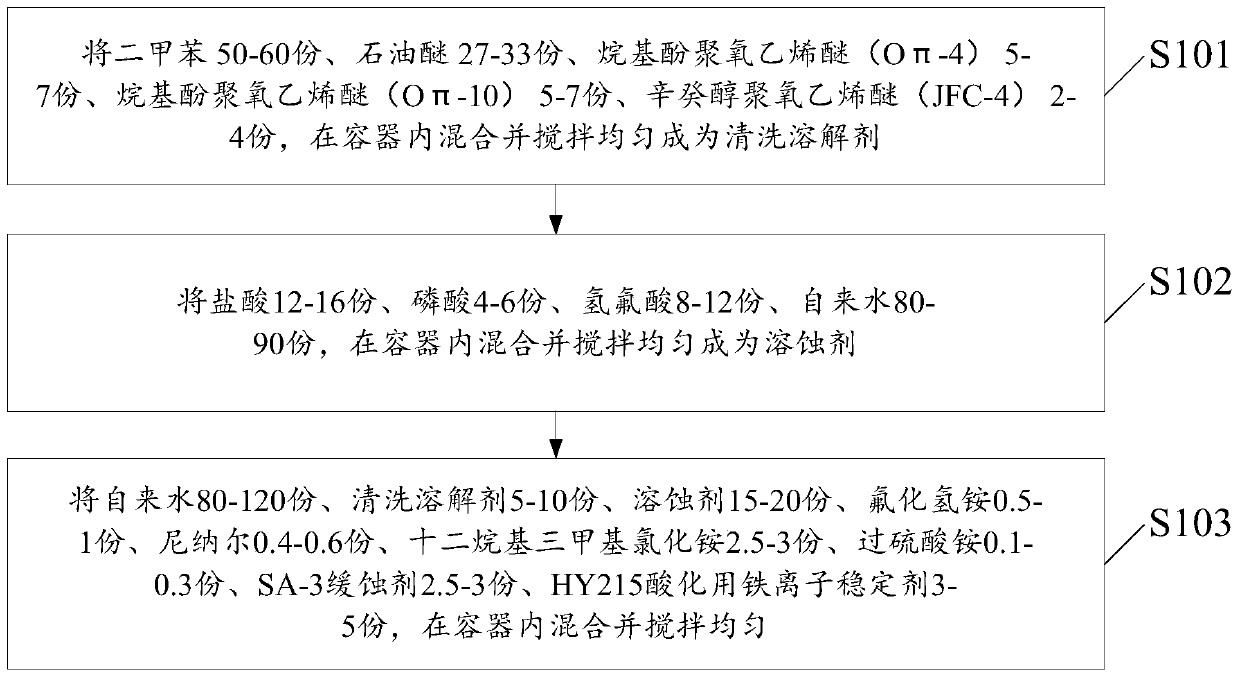

[0061] Based on the same inventive concept, this embodiment provides a method for preparing a multi-element synergistic plug-removing agent, such as figure 1 shown, including:

[0062] Step S101: 50-60 parts of xylene, 27-33 parts of petroleum ether, 5-7 parts of alkylphenol polyoxyethylene ether (Oπ-4), 5-7 parts of alkylphenol polyoxyethylene ether (Oπ-10) Parts, 2-4 parts of octadecyl alcohol polyoxyethylene ether (JFC-4), mix and stir in the container to become a cleaning solvent.

[0063] Step S102: Mix 12-16 parts of hydrochloric acid, 4-6 parts of phosphoric acid, 8-12 parts of hydrofluoric acid, and 80-90 parts of tap water in a container and stir evenly to form a corrosion agent.

[0064] Step S103: mix 80-120 parts of tap water, 5-10 parts of cleaning solvent, 15-20 parts of corrosion agent, 0.5-1 part of ammonium bifluoride, 0.4-0.6 part of Ninar, dodecyltrimethylammonium chloride 2.5-3 parts, 0.1-0.3 parts of ammonium persulfate, 2.5-3 parts of SA-3 corrosion inh...

Embodiment approach

[0070] The first one can be 120 parts by mass of tap water, 5 parts of cleaning solvent, 15 parts of corrosion agent, 0.5 part of ammonium bifluoride, 0.4 part of Ninar, 2.5 parts of dodecyltrimethylammonium chloride, persulfuric acid 10 tons of the multi-component synergistic plug-removing agent were prepared at the ratio of 0.1 parts of ammonium, 2.5 parts of SA-3 corrosion inhibitor, and 3 parts of iron ion stabilizer for HY215 acidification. When in use, it is transported to the construction site and injected into the target layer by a cement truck. According to indoor tests, the dissolution rate of organic plugs is 81%, the dissolution rate of inorganic plugs is 91%, the degradation rate of polymer plugs is 72%, and the recovery rate of core permeability is 86%.

[0071] The second one can be 80 parts of tap water, 10 parts of cleaning solvent, 20 parts of corrosion agent, 1 part of ammonium bifluoride, 0.6 parts of Ninar, 3 parts of dodecyltrimethylammonium chloride, 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com