Automatic locking structure of adjusting screw rod for flow-adjustable metering pump

A technology for adjusting screw and flow measurement, which is applied to the components of the pumping device for elastic fluid, the pump, and the pump control. The effect of easy availability of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

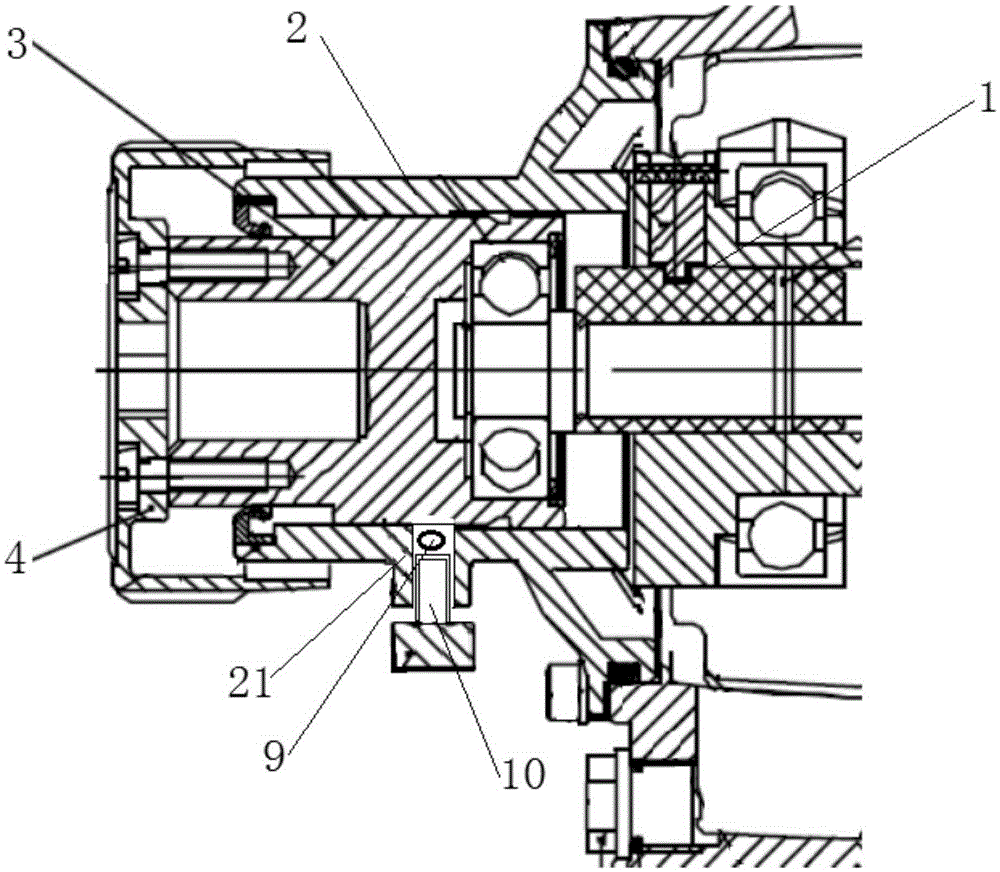

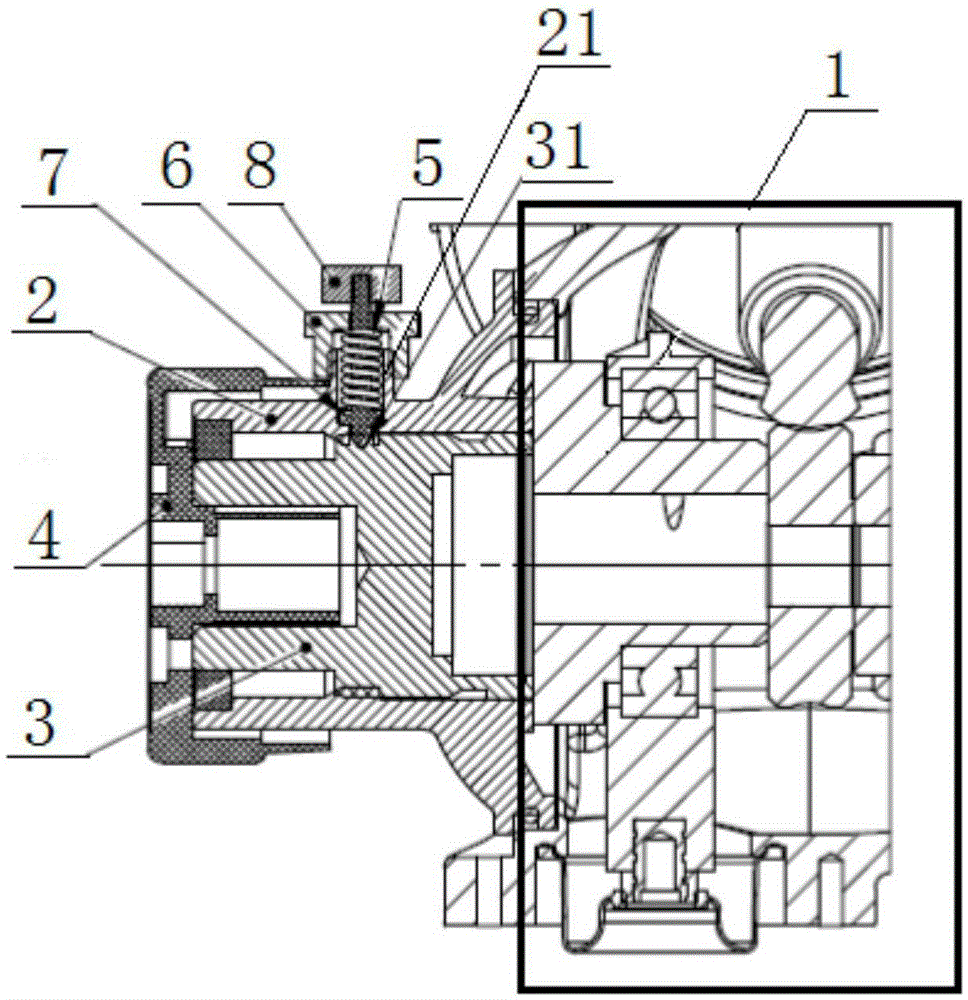

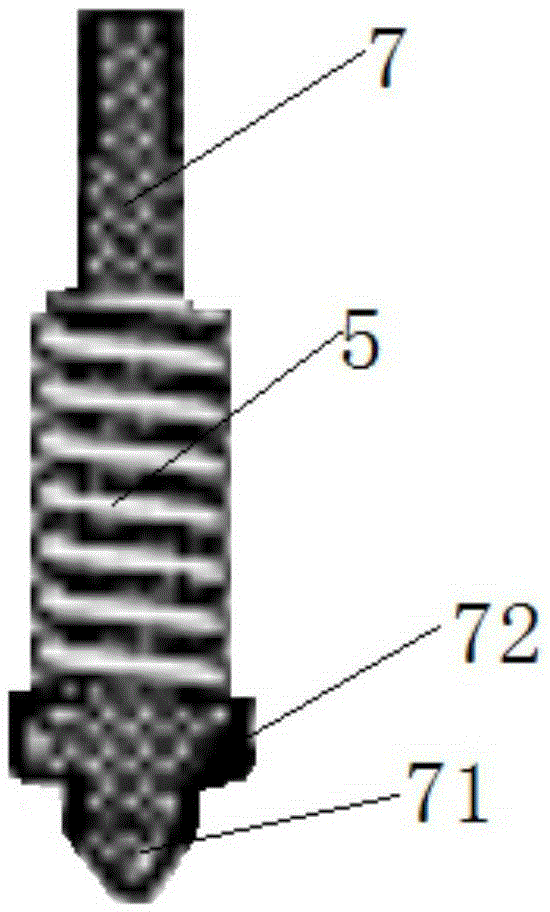

[0022] Such as figure 2 , image 3 As shown, the adjustable flow metering pump uses the automatic locking structure of the adjusting screw. The adjustable flow metering pump includes a driving end 1, a side cover 2, an adjusting screw 3 and an adjusting handle 4. The side cover 2 is connected with the driving end 1 to adjust The screw rod 3 is located inside the side cover 2, and is driven by threads with the side cover 2. The adjustment handle 4 is located outside the side cover 2 and connected with the adjustment screw rod 3. When the adjustment handle 4 is rotated, the adjustment handle 4 drives the adjustment screw rod 3 to move Finally adjust the eccentricity, and then adjust the flow rate of the adjustable flow metering pump. The automatic locking structure includes a spring 5, a spring cover 6 and a locking spring seat 7. The inner end of the locking spring seat 7 is the locking end, and the outer end is the free end. end, and the middle part is the guide rod for sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com