Calibration system and method for a large workpiece

A technology for large workpieces and calibration methods, applied in measuring devices, instruments, optical devices, etc., can solve problems such as object deformation, data errors, visual errors, etc., and achieve high accuracy, easy operation, and good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

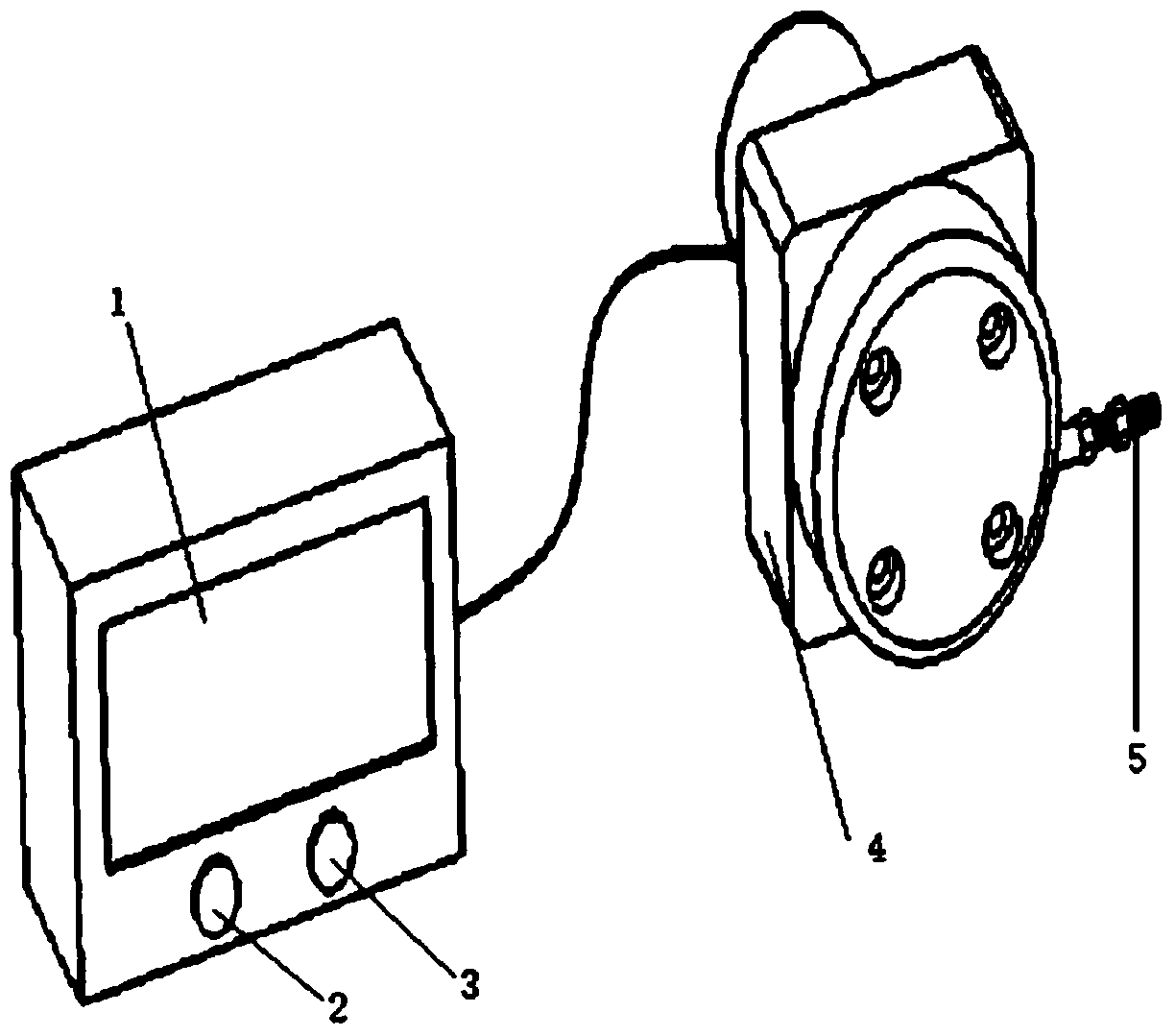

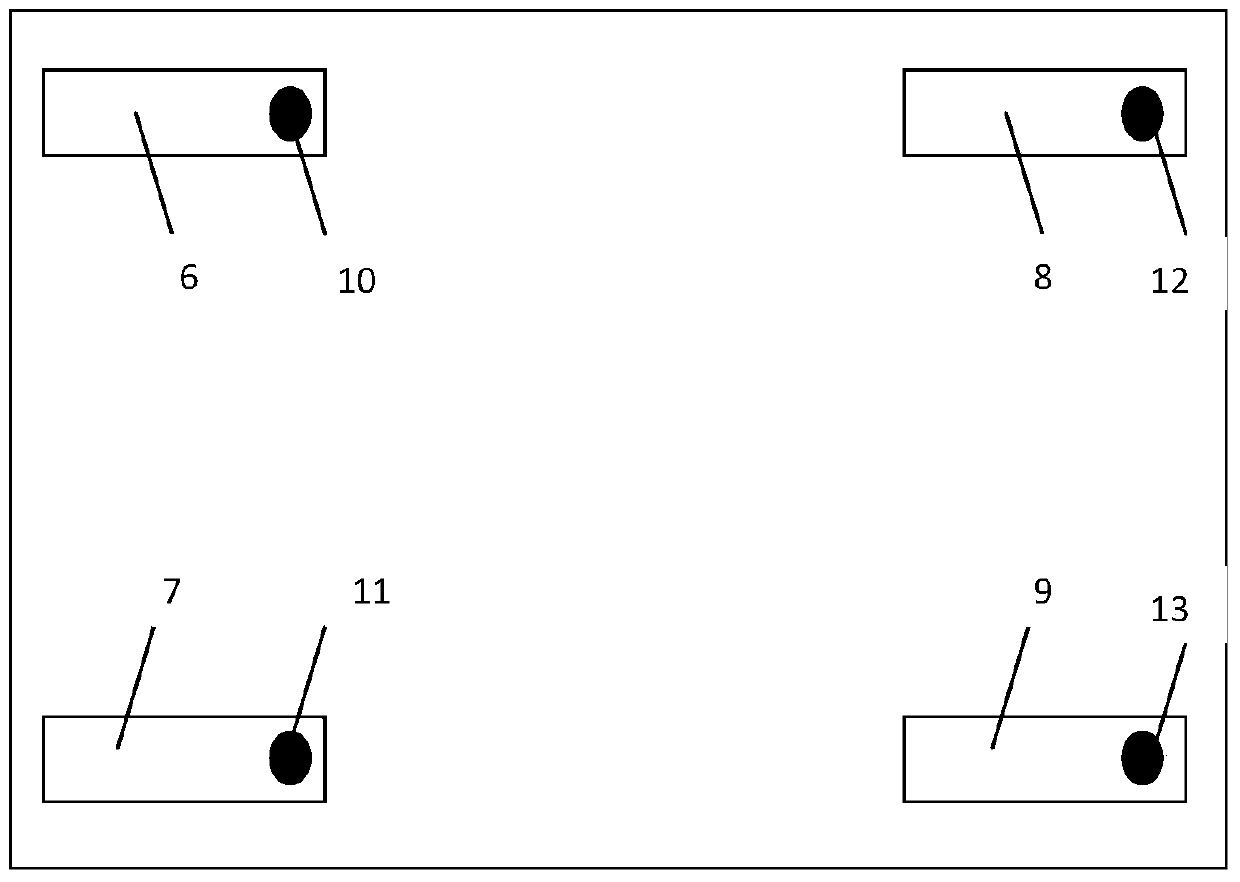

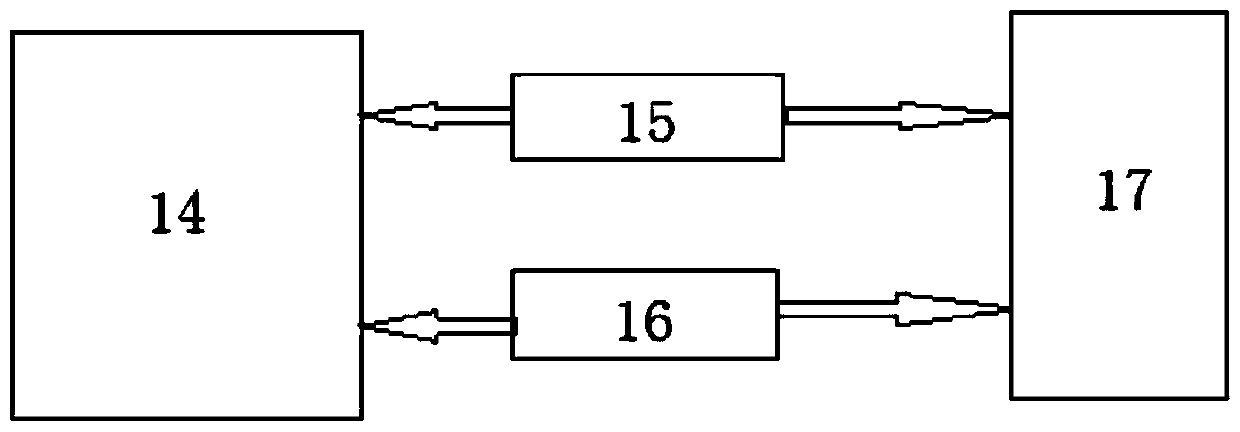

[0043] Such as figure 1 , figure 2 As shown, a calibration system for large workpieces, a calibration system for large workpieces, including one-dimensional code 6, one-dimensional code 7, one-dimensional code 8, one-dimensional code 9; mark point 10, mark point 11, mark point 12. Marker point 13 and distance measuring device 15, high-definition camera 16 and computer 17.

[0044] The distance measuring device 15 includes a distance measuring instrument 4, the distance measuring instrument 4 is provided with a pull wire end 6, and the distance measuring instrument 4 is also connected with the start measurement button 2, the stop measurement button 3 and the distance value display Screen 1 is connected,

[0045] The distance measuring instrument 4 and the camera 16 are all connected to the computer 17 .

[0046]Among them, the one-dimensional code 6, the one-dimensional co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com