Equipment for assembling front valve and rear valve of mechanism of diaphragm gas meter

A membrane gas meter and assembly equipment technology, which is applied in metal processing equipment, assembly machines, measuring devices, etc., can solve the problems of low efficiency, large installation error, and complicated operation of the front and rear flags of the gas meter, and achieve accurate positioning and low manufacturing cost. Low, simple structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

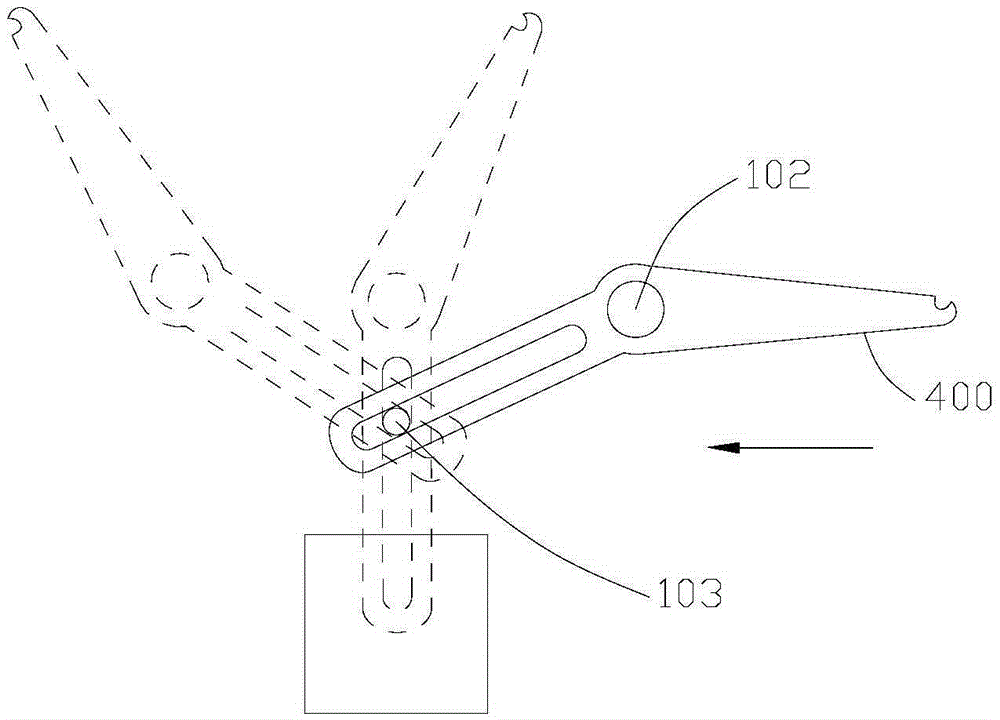

[0033] The installation of the front and rear flags of the existing gas meter is divided into three parts. The front and rear flags are respectively assembled into the bellows, and the vertical shaft is inserted; then, the front and rear flags are raised with gaskets, and the vertical shaft is pressed into place on the press-fitting device. ;Finally, the sealing ring gland on the vertical shaft that is pressed into place is pressed tightly. Because it is divided into three parts, the operation requires more manpower, and at the same time, the operators are prone to fatigue and the efficiency is not high.

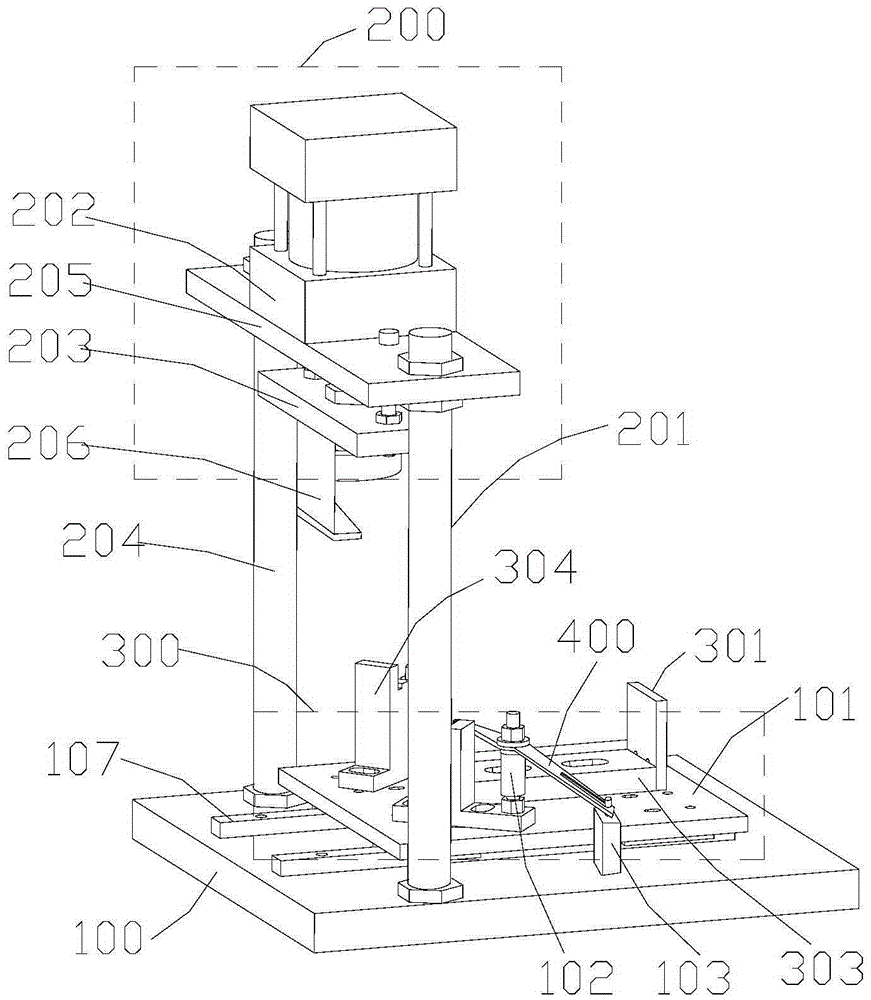

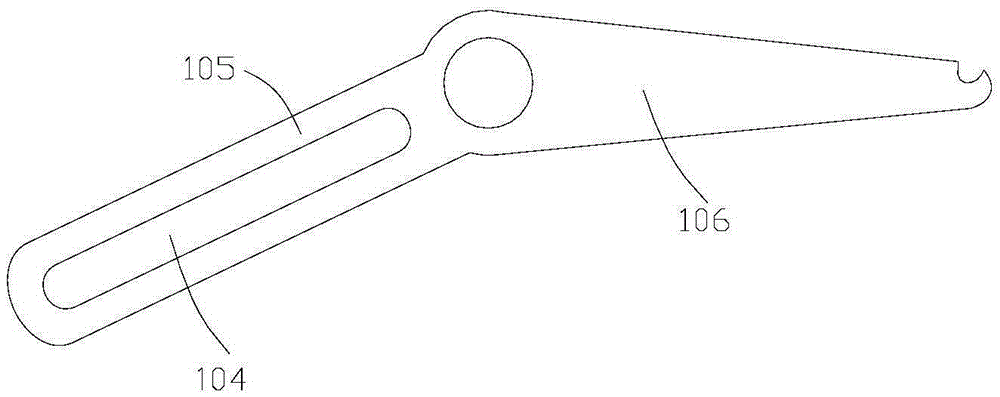

[0034] In view of this, the designer of the present invention has designed a kind of membrane type gas meter movement front and rear flag assembly equipment, and this assembly equipment structure is simple and reasonable, easy to use; Slide to make the membrane gas meter movement below the press-fitting mechanism. At the same time, the gasket is located at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com