Testing device for simulating static pressure pile-sinking process of steel pipe pile under confining pressure condition and method of testing device

A technology of static pressure steel pipe pile and test device, which is applied in the test of basic structure, the use of stable tension/pressure to test the strength of materials, and basic structure engineering, etc. The effect of multiple industrial replication and standard unification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

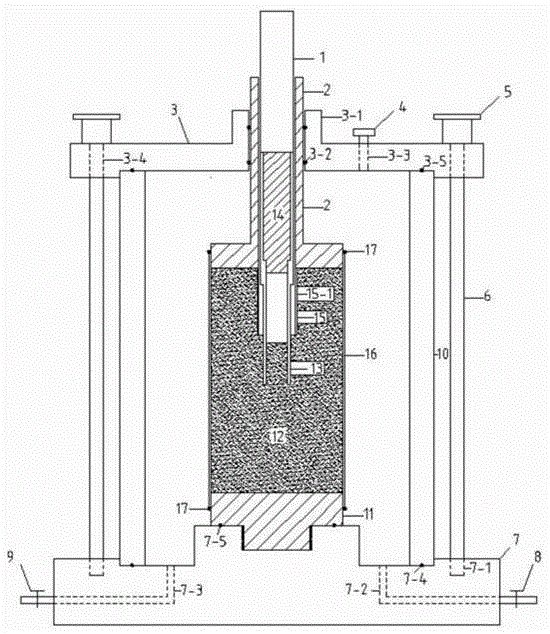

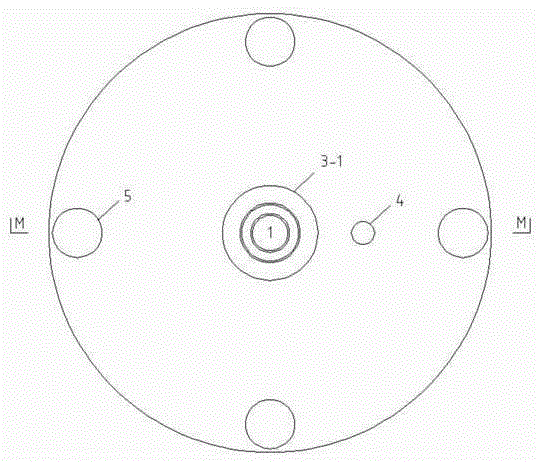

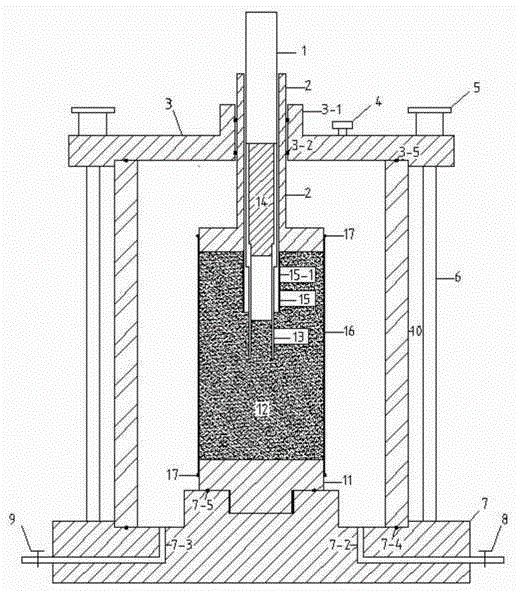

[0068] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0069] 1. Device

[0070] 1. Overall

[0071] like figure 1 , 2, 3. The device includes guide rod 1, guide pipe 2, upper cover plate 3, exhaust cap 4, nut 5, screw rod 6, lower cover plate 7, drain valve 8, water injection valve 9, pressure chamber 10, base 11 , rock sample 12, steel pipe pile 13, rubber plug 14, round hole 15, latex film 16 and rubber band 17;

[0072] The upper cover 3 is provided with a guide hole 3-1, a guide hole sealing ring 3-2, an exhaust hole 3-3, a perforation 3-4 and an upper cover sealing ring 3-5;

[0073] The lower cover 7 is provided with a threaded hole 7-1, a drainage hole 7-2, a water injection hole 7-3, a lower cover sealing ring 7-4 and a base sealing ring 7-5;

[0074] The steel pipe pile 13 is bounded by the pile shoulder 13-1, and is composed of an upper thick cylinder and a lower thin cylinder, and a rubber plug 14 is placed in the thick cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com