A robot for detecting the inner wall of a large steel container

A technology for steel containers and robots, applied in manipulators, motor vehicles, manufacturing tools, etc., can solve the problems of high height, time-consuming and laborious, and large stainless steel containers, and achieve the effect of strengthening magnetic adsorption and preventing deep corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

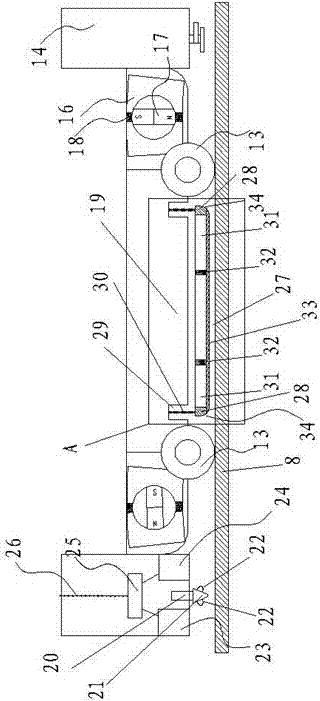

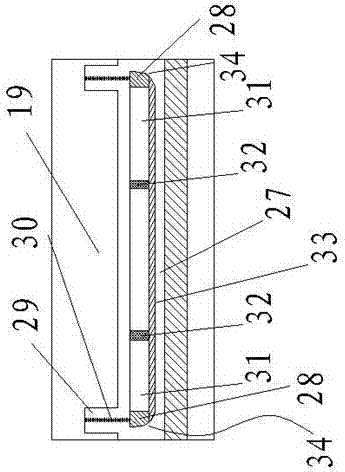

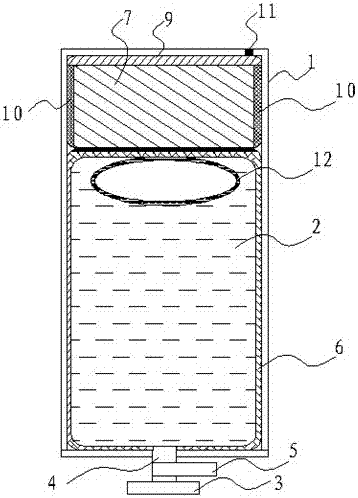

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0029] Such as Figure 1-Figure 3 As shown, a large-scale steel container inner wall detection robot includes a vehicle frame 19 and rollers 13 arranged at the bottom of the vehicle frame 19 for cooperating with the container inner wall 8. Close to the magnetic adsorption part of container inner wall 8; Described vehicle frame 19 is also provided with the image acquisition assembly that is used to collect container inner wall 8 graphic information, and described vehicle frame 19 is also provided with spraying assembly 14; Described magnetic adsorption part is Magnetic seat, described magnetic seat comprises external soft magnetic material shell 16 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com